Quick-setting emulsified asphalt cold patch material and preparation method thereof

A technology of emulsified asphalt and cold patch, which is applied in the field of road construction materials, can solve problems such as insufficient adhesion between the cold patch and the original base surface, shortened service life of the cold patch, and delamination of the interface to improve mechanical properties. Performance and bonding performance, fast strength formation, rapid formation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

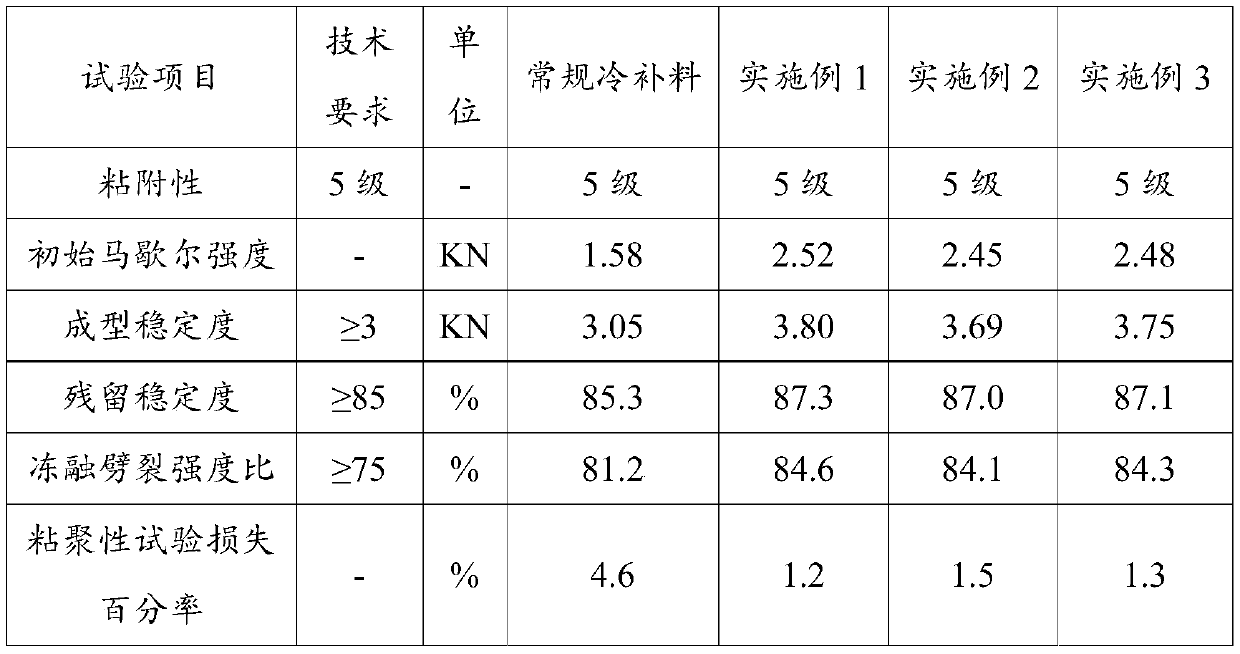

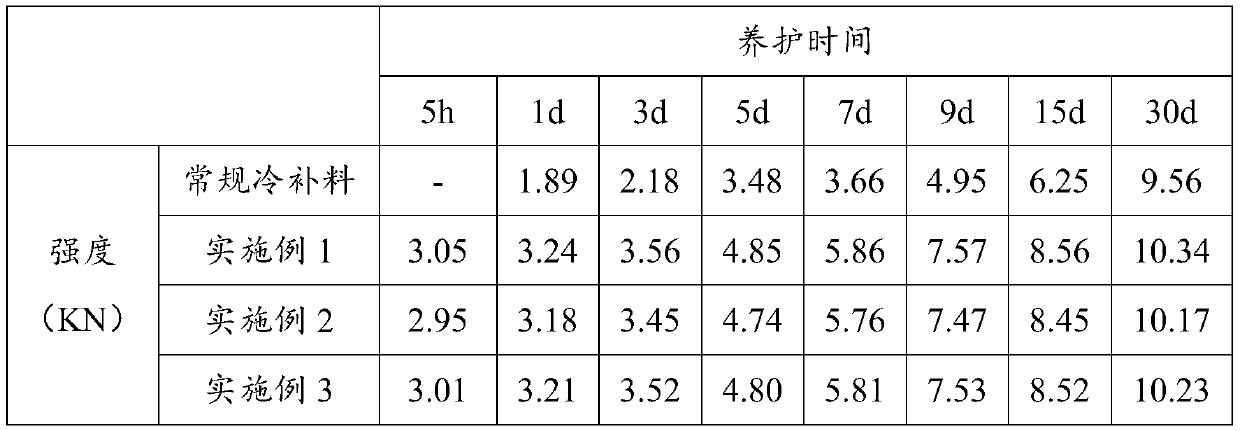

Embodiment 1

[0039] This embodiment provides a quick-setting emulsified asphalt cold patch, which is composed of quick-setting anionic emulsified asphalt, a coagulation-accelerating film-forming agent and mineral materials in a weight ratio of 1:1.8:16.6. in,

[0040] The coagulant film-forming agent is composed of calcium chloride powder and water in a weight ratio of 15:85.

[0041] The quick-setting anionic emulsified asphalt is composed of the following raw materials in terms of weight percentage: 60% linear SBS modified asphalt, 1.5% anionic emulsifier and 38.5% water. The solid content of the quick-setting anionic emulsified asphalt is 55% to 60%, and the linear SBS content in the linear SBS modified asphalt is 4.5%.

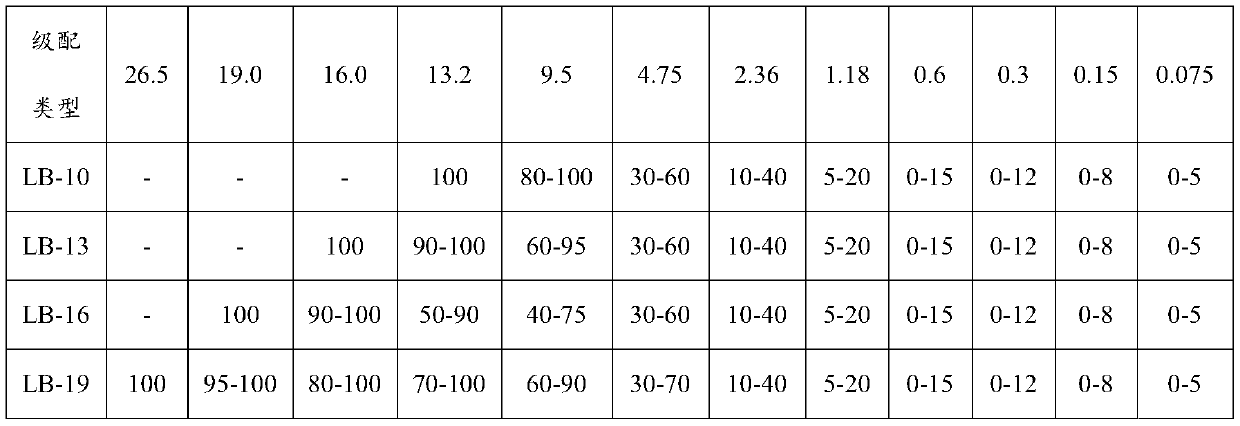

[0042] The mineral material is composed of coarse aggregate, fine aggregate, waste recycled RAP and mineral powder, and the weight ratio of coarse aggregate, fine aggregate, waste recycled RAP and mineral powder is 28:26:42:4. Coarse aggregates are selected from grav...

Embodiment 2

[0054] This embodiment provides a quick-setting emulsified asphalt cold patch, which is composed of quick-setting anionic emulsified asphalt, a coagulation-accelerating film-forming agent and mineral materials in a weight ratio of 1:1.2:12.5. in,

[0055] The film-accelerating agent is composed of magnesium chloride powder and water in a weight ratio of 10:90.

[0056] The quick-setting anionic emulsified asphalt is composed of the following raw materials in terms of weight percentage: 55% of linear SBS modified asphalt, 1.2% of anionic emulsifier and 43.8% of water. The solid content of the quick-setting anionic emulsified asphalt is 55% to 60%, and the linear SBS content in the linear SBS modified asphalt is 4.5%.

[0057] The mineral material is composed of coarse aggregate, fine aggregate, waste recycled RAP and mineral powder, and the weight ratio of coarse aggregate, fine aggregate, waste recycled RAP and mineral powder is 22:22:50:6. Coarse aggregates are selected fro...

Embodiment 3

[0069] This embodiment provides a quick-setting emulsified asphalt cold patch, which is composed of quick-setting anionic emulsified asphalt, a coagulation-accelerating film-forming agent and mineral materials in a weight ratio of 1:1.5:14. in,

[0070] The coagulant film-forming agent is composed of sodium chloride powder and water in a weight ratio of 13:87.

[0071] The quick-setting anionic emulsified asphalt is composed of the following raw materials in terms of weight percentage: 58% linear SBS modified asphalt, 1.4% anionic emulsifier and 40.6% water. The solid content of the quick-setting anionic emulsified asphalt is 55% to 60%, and the linear SBS content in the linear SBS modified asphalt is 4.5%.

[0072] Mineral materials are composed of coarse aggregate, fine aggregate, waste recycled RAP and mineral powder. The weight ratio of coarse aggregate, fine aggregate, waste recycled RAP and mineral powder is 35:32:30:3. Coarse aggregates are selected from gravel or was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com