Imitation stone product as well as preparation method and application thereof

A technology of imitating stone and products, applied in the field of imitating stone products and their preparation, can solve the problems of not conforming to the trend of sustainable development, high price of natural stone, etc., and achieve good social and economic benefits, enrich the variety of products, and reduce the effect of mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

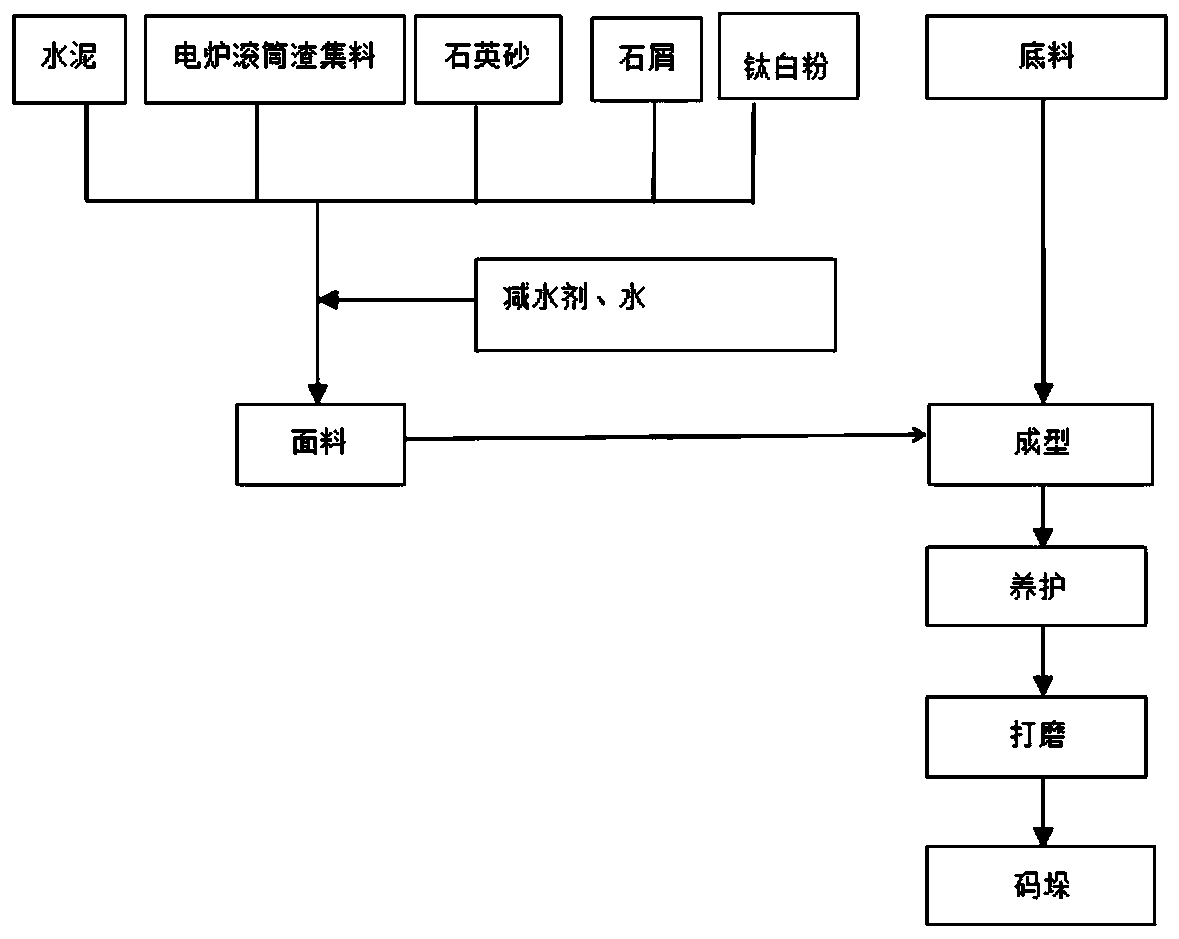

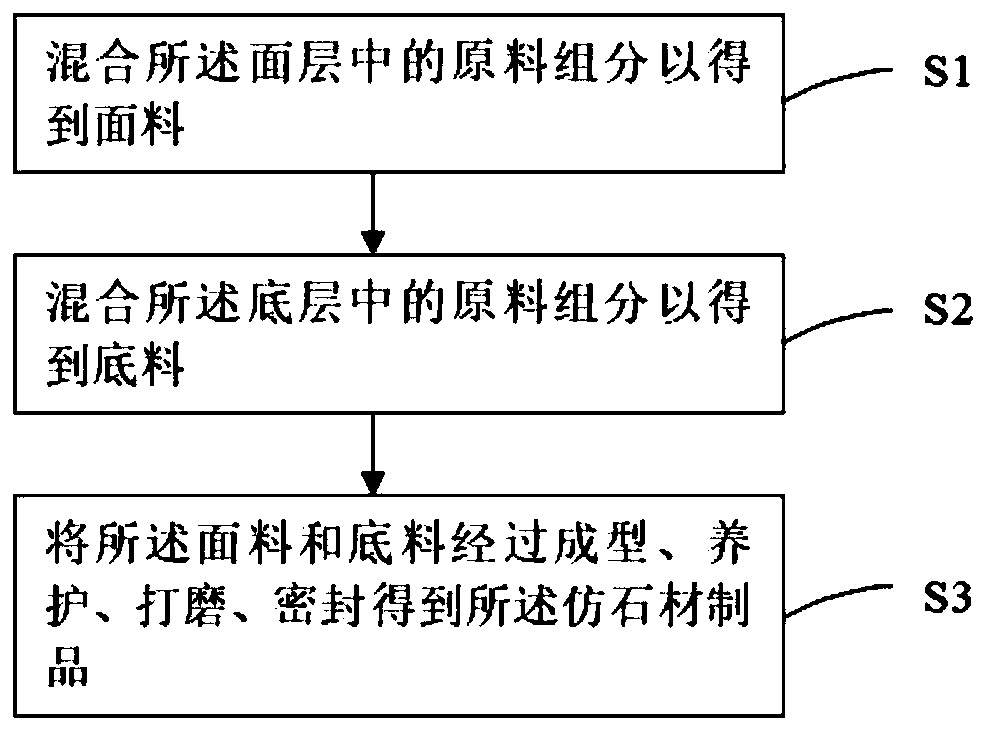

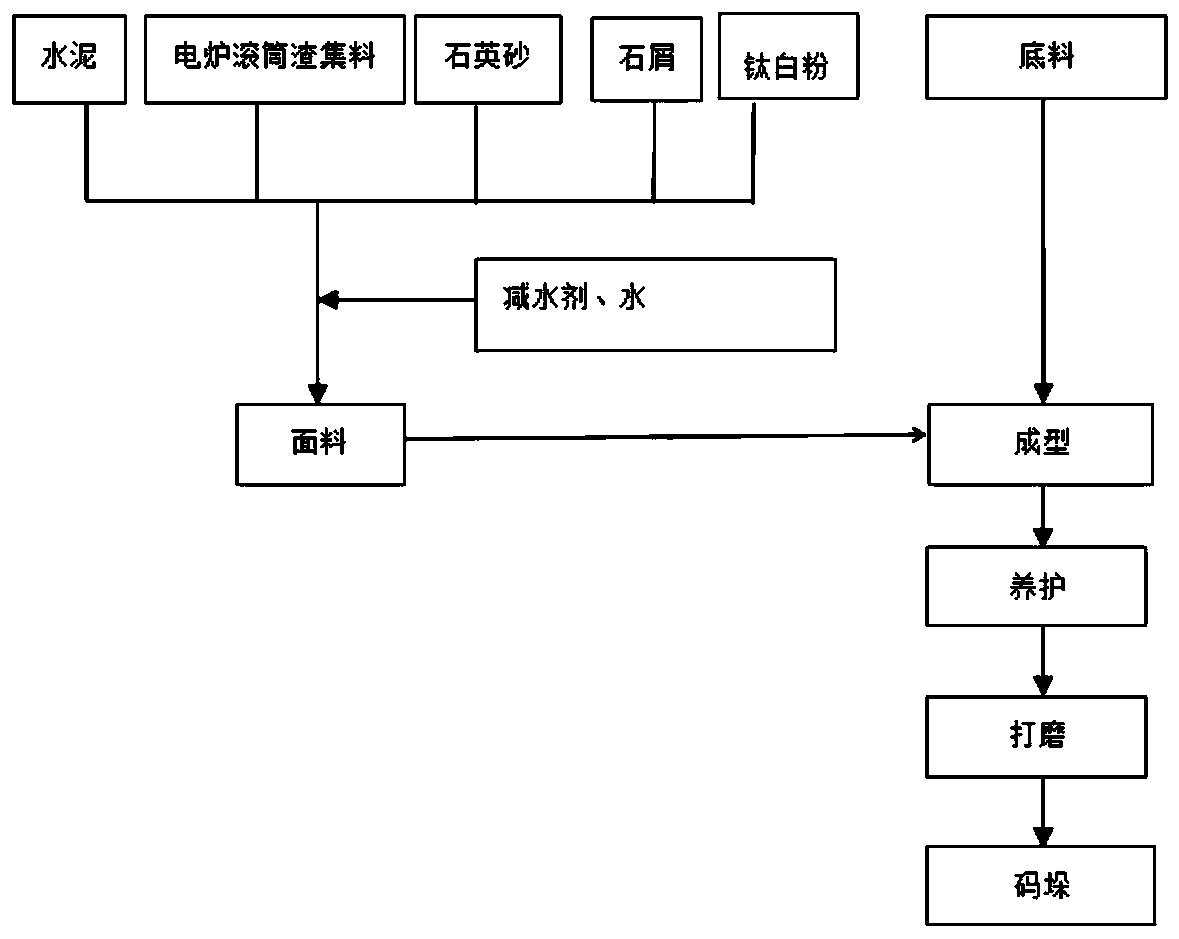

[0032] Such as figure 1 and figure 2 Shown, the present invention also provides a kind of preparation method of above-mentioned imitation stone material product, described method comprises three steps of S1-S3:

[0033] S1: mixing the raw material components in the surface layer to obtain a fabric;

[0034] S2: mixing the raw material components in the bottom layer to obtain the bottom layer;

[0035] S3: forming, curing, polishing, and sealing the surface material and base material to obtain the imitation stone product.

[0036]In step S1, the mixing of the raw material components in the surface layer may include first weighing the electric furnace drum slag aggregate, quartz sand, stone chips, and titanium dioxide, and feeding them into a fabric mixer for stirring for 20-30 seconds, and then weighing the Put the good cement and admixture into the fabric mixer and stir evenly for 40-50 seconds to become a uniformly mixed dry material, and then add water and stir at a cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com