Engineering plastic with stable size, and preparation method thereof

An engineering plastics, dimensionally stable technology, applied in the field of plastics, can solve the problems of insufficient, unstable product size, easy shrinkage and deformation, etc., to achieve the effect of simple processing technology, improved processing stability, and not easy to change color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

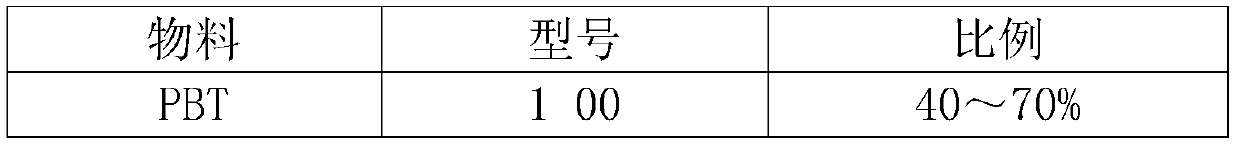

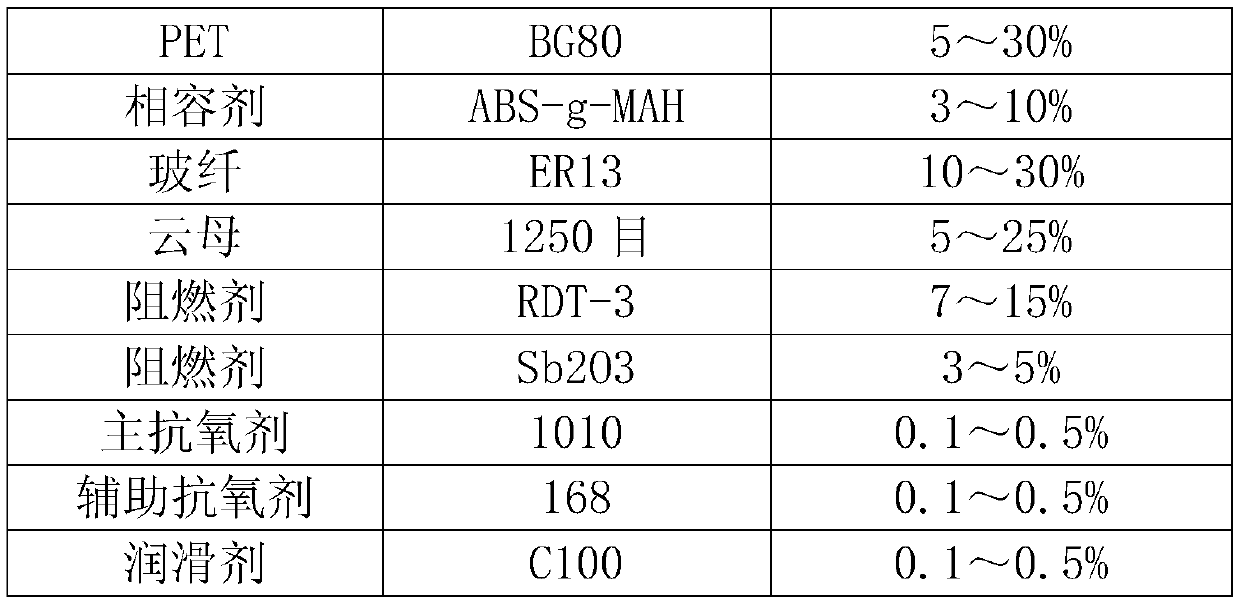

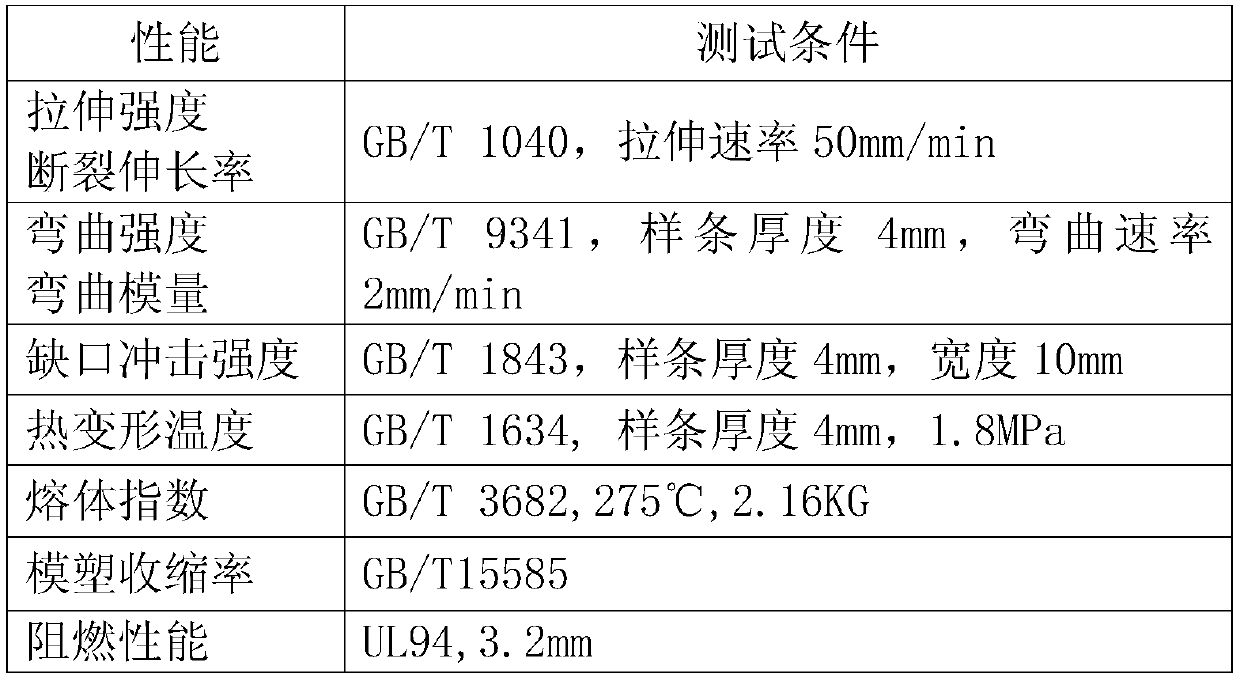

[0027] The dimensionally stable engineering plastics include 40-70% of PBT, 5%-30% of PET, 3%-10% of compatibilizer, 10%-30% of glass fiber, 5%-25% of mica, flame retardant 10% to 20% of antioxidants, 0.1% to 0.5% of primary antioxidants, 0.1% to 0.5% of auxiliary antioxidants and 0.1% to 0.5% of lubricants. This engineering plastic blends PBT and PET with alloys, which not only maintains the excellent properties of the original polymers, but also improves the performance of the respective polymers. The PBT material obtained by blending PBT and PET has both dimensional stability. Good, and has good heat resistance and processability. At present, many electrical appliances such as the upper cover of the induction cooker use PBT / PET alloy engineering materials.

[0028] The compatibilizer is a compound mixture of ABS-g-MAH; ABS resin is acrylonitrile-butadiene-styrene terpolymer, which has good dimensional stability, and ABS-g-MAH is a good compatibilizer , can increase the com...

no. 2 example

[0044] This dimensionally stable engineering plastic is different from the first embodiment in that it includes 50% by weight of PBT, 15% of PET, 3% of compatibilizer, 10% of glass fiber, 10% of mica, and 9% of decabromodiphenylethane , antimony trioxide 3%, primary antioxidant 0.15%, auxiliary antioxidant 0.15% and lubricant 0.5%.

[0045] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

no. 3 example

[0047] This dimensionally stable engineering plastic is different from the first embodiment in that it includes 45% by weight of PBT, 15% of PET, 3% of compatibilizer, 10% of glass fiber, 15% of mica, and 9% of decabromodiphenylethane , antimony trioxide 3%, primary antioxidant 0.15%, auxiliary antioxidant 0.15% and lubricant 0.5%.

[0048] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com