Foam control method in a kind of rhamnolipid fermentation process

A fermentation process and rhamnolipid technology, applied in the biological field, can solve problems such as affecting the fermentation efficiency, reducing the effective utilization volume of the fermenter, etc., achieving the effects of simple process operation, reducing the risk of contamination, and solving liquid escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

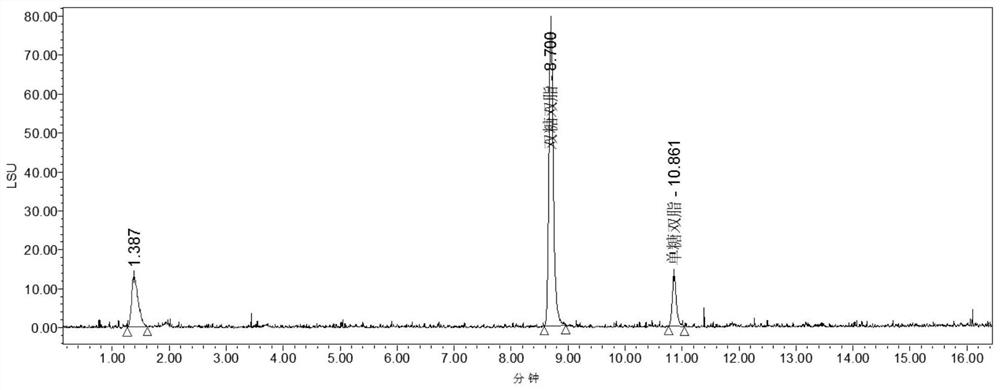

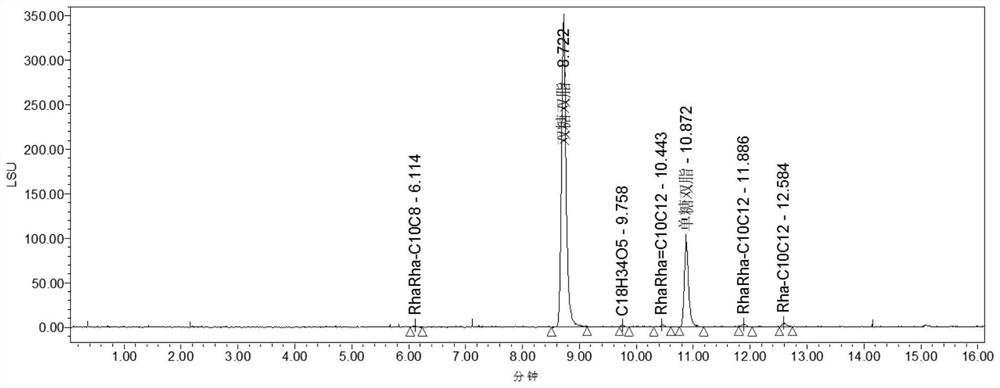

Image

Examples

Embodiment 1

[0037] 1. Pick a single colony of Pseudomonas aeruginosa (Pseudomonas aeruginosa) KT1115 from the agar solid plate with an inoculation loop and inoculate it into the seed medium, culture at 30° C. and 200 rpm for 21 hours to obtain a seed solution.

[0038]The composition of the above-mentioned seed medium is as follows: peptone 10g / L, yeast powder 5g / L, NaCl 10g / L, and the balance is water.

[0039] 2. The seed liquid cultivated in step 1 is inoculated in the fermentation medium of a 7L fermenter (50% of filling capacity) by an inoculum size of 10% (volume ratio) to start fermentation and cultivation, and the initial OD600 after inoculation is 4.2, The fermentation conditions are: temperature 30° C., ventilation rate 1 vvm, stirring speed 300 rpm. During the fermentation process, the pH of the fermentation broth and the pressure of the fermenter are simultaneously adjusted at different stages, specifically: 0-6h, control the pH to 6.5, and the pressure of the fermenter to 0.0...

Embodiment 2

[0047] In addition to regulating the pH of the fermented liquid and the pressure of the fermenter simultaneously in different stages according to the following method during the fermentation process, repeat the steps of Example 1 to obtain the fermented liquid fermented for 10 days:

[0048] 0-6h, control the pH to 5, the pressure of the fermenter is 0.02MPa; 6-96h, control the pH to 6.5, the pressure of the fermenter is 0.04MPa; after 96h, control the pH to 5, the pressure of the fermenter is 0.015MPa.

[0049] After testing, the yield of rhamnolipid reached 0.52g / L / h.

Embodiment 3

[0051] In addition to regulating the pH of the fermented liquid and the pressure of the fermenter simultaneously in different stages according to the following method during the fermentation process, repeat the steps of Example 1 to obtain the fermented liquid fermented for 10 days:

[0052] 0-6h, control the pH to 8.5, the pressure of the fermenter is 0.035MPa; 6-96h, control the pH to 5.3, the pressure of the fermenter is 0.015MPa; after 96h, control the pH to 7.5, the pressure of the fermenter is 0.04MPa.

[0053] After testing, the yield of rhamnolipid reached 0.54g / L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com