Light-resistant fatting agent intermediate

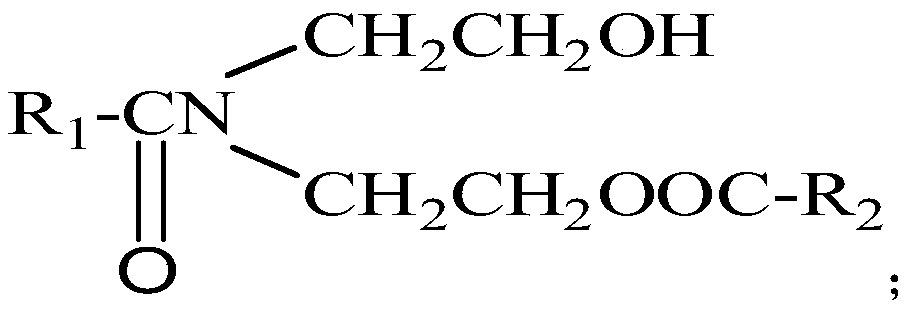

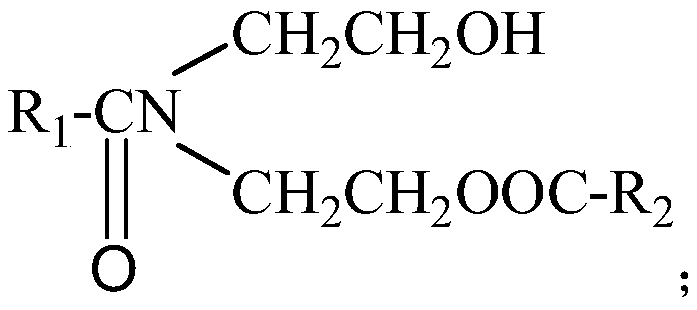

A fatliquoring agent and intermediate technology, which is applied in the field of lightfast fatliquoring agent intermediates, can solve the problems of poor lightfastness of fatliquor, not suitable for light-colored leather, and limited application range, etc., and achieve good lightfastness and good softness And natural luster, improve the effect of compounding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

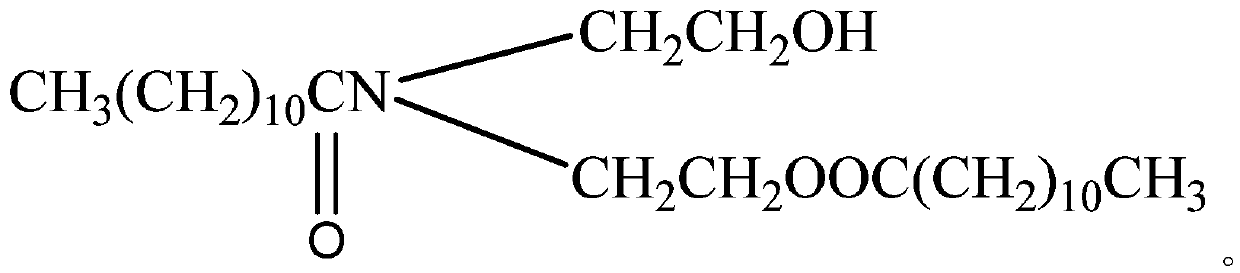

[0021] A preparation method of a light-resistant type fatliquoring agent intermediate, comprising the following steps:

[0022] Step 1: Add 1 mol of diethanolamine and 0.95 mol of lauric acid into the reaction vessel, stir and mix, and mix well to form the first mixed liquid; then raise the temperature of the first mixed liquid to 140°C and react until the first mixed liquid Amine value in liquid≤10.0mgKOH / g;

[0023] Step 2: At a temperature of 80°C, add 1.1 mol of lauric acid and catalyst p-toluenesulfonic acid into the reaction vessel of step 1, stir and mix, and form the second mixed solution after mixing evenly; then the temperature of the second mixed solution After rising to 140°C, the reaction is carried out until the amine value in the second mixed solution is ≤5.0mgKOH / g, and the acid value is ≤10.0mgKOH / g; after the reaction is completed, the material is discharged at a temperature of 70°C to obtain light resistance Type fatliquor intermediate. (wherein the cataly...

Embodiment 2

[0027] A preparation method of a light-resistant type fatliquoring agent intermediate, comprising the following steps:

[0028] Step 1: Add 1 mol of diethanolamine and 0.95 mol of myristic acid into the reaction vessel, stir and mix, and mix well to form the first mixed liquid; then raise the temperature of the first mixed liquid to 140°C and react until the first mixed liquid Amine value in liquid≤10.0mgKOH / g;

[0029] Step 2: At a temperature of 80°C, add 1.1 mol of myristic acid and the catalyst p-toluenesulfonic acid into the reaction vessel of step 1 and stir to mix, and form the second mixed liquid after mixing evenly; then the temperature of the second mixed liquid is After rising to 140°C, the reaction is carried out until the amine value in the second mixed solution is ≤5.0mgKOH / g, and the acid value is ≤10.0mgKOH / g; after the reaction is completed, the material is discharged at a temperature of 70°C to obtain light resistance Type fatliquor intermediate. (wherein t...

Embodiment 3

[0035] A preparation method of a light-resistant type fatliquoring agent intermediate, comprising the following steps:

[0036]Step 1: Add 1 mol of diethanolamine and 0.95 mol of palmitic acid into the reaction vessel, stir and mix, and mix uniformly to form the first mixed solution; then raise the temperature of the first mixed solution to 140°C and react until the first The amine value in the mixture is ≤10.0mgKOH / g;

[0037] Step 2: Add 1.1 mol of 12-hydroxystearic acid and catalyst p-toluenesulfonic acid into the reaction vessel of step 1 at a temperature of 80°C, stir and mix, and mix well to form a second mixed solution; then add the second After the temperature of the second mixed liquid is raised to 140°C, the reaction is carried out until the amine value in the second mixed liquid is ≤5.0mgKOH / g, and the acid value is ≤10.0mgKOH / g; material, to obtain light-resistant type fatliquoring agent intermediate. (wherein the quality of catalyst in step two is 0.4% of the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com