Tin surface protective agent and preparation method thereof

A technology of protective agent and mixture, applied in chemical/electrolytic methods to remove conductive materials, printed circuit manufacturing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

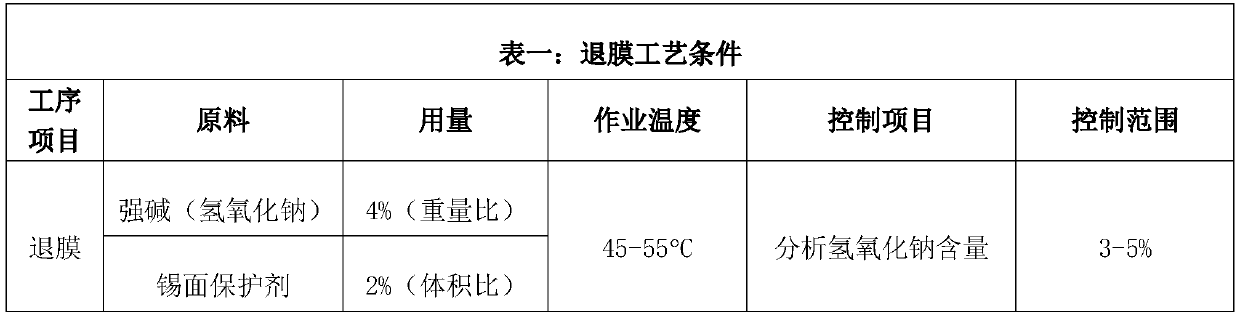

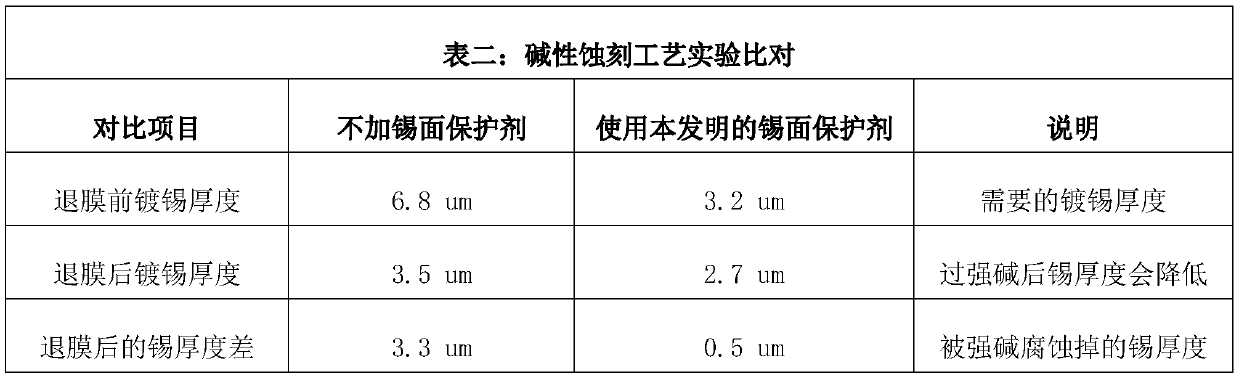

Method used

Image

Examples

Embodiment 1

[0022] S1. Mix and stir 0.5kg of monoethanolamine and 44kg of water until monoethanolamine is completely dissolved to obtain a primary mixture;

[0023] S2. Add 1.0 kg polyethylene glycol 300 into the primary mixture and mix and stir until the polyethylene glycol 300 is completely dissolved to obtain the secondary mixture;

[0024] S3, adding 5.0 kg of hexamethylenetetramine into the secondary mixture and stirring and mixing until the hexamethylenetetramine is completely dissolved to obtain the tertiary mixture;

[0025] S4, adding 5.0kg of urea to the three mixtures and stirring and mixing until the urea is completely dissolved to obtain the four mixtures;

[0026] S5. Add 0.2kg of benzotriazole into the mixture of four times and stir and mix until the benzotriazole is completely dissolved to obtain the mixture of five times;

[0027] S6. Add 0.1kg 2-thiouracil to the mixture for five times and stir and mix until the thiouracil is completely dissolved to obtain the mixture f...

Embodiment 2

[0031] S1. Mix and stir 1.0kg of monoethanolamine and 40kg of water until the monoethanolamine is completely dissolved to obtain a primary mixture;

[0032] S2. Add 0.5kg polyethylene glycol 300 into the primary mixture and mix and stir until the polyethylene glycol 300 is completely dissolved to obtain the secondary mixture;

[0033] S3, adding 8.0 kg of hexamethylenetetramine into the secondary mixture and stirring and mixing until the hexamethylenetetramine is completely dissolved to obtain the tertiary mixture;

[0034] S4, adding 10.0kg of urea to the three mixtures and stirring and mixing until the urea is completely dissolved to obtain the four mixtures;

[0035] S5. Add 0.2kg of benzotriazole into the mixture of four times and stir and mix until the benzotriazole is completely dissolved to obtain the mixture of five times;

[0036] S6. Add 0.1kg 2-thiouracil to the mixture for five times and stir and mix until the thiouracil is completely dissolved to obtain the mixtu...

Embodiment 3

[0040] S1. Mix and stir 0.8kg monoethanolamine and 46.3kg water until the monoethanolamine is completely dissolved to obtain a primary mixture;

[0041] S2. Add 0.9kg polyethylene glycol 300 into the primary mixture and mix and stir until the polyethylene glycol 300 is completely dissolved to obtain the secondary mixture;

[0042] S3. Add 3.0 kg of hexamethylenetetramine into the secondary mixture and stir and mix until the hexamethylenetetramine is completely dissolved to obtain the tertiary mixture;

[0043] S4, adding 2.0kg of urea to the three mixtures and stirring and mixing until the urea is completely dissolved to obtain the four mixtures;

[0044] S5. Add 0.1 kg of benzotriazole to the mixture of four times and stir and mix until the benzotriazole is completely dissolved to obtain the mixture of five times;

[0045] S6. Add 0.3kg 2-thiouracil to the mixture for five times and stir and mix until the thiouracil is completely dissolved to obtain the mixture for six times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com