A kind of packaging paper for cold chain liquid and its production process

A wrapping paper and liquid technology, applied in the directions of wrapping paper, wrapping paper, packaging, etc., can solve the problems of low roughness, low requirements on printing surface clarity, and extremely high requirements, so as to improve the degree of smoothness and fineness, improve the color and luster. Brightness, the effect of improving the stiffness of the finished paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The cold chain liquid wrapping paper and its production process of the present invention adopt the dual-component sizing process in the machine, and simultaneously meet the dual requirements of continuous water resistance and lactic acid resistance of the liquid-wrapped paper; The combined coating method maximizes the smoothness and fineness of the printed surface of the finished paper. In addition, the coating can not only quickly absorb the printing ink, but also effectively prevent the ink from migrating to the inside of the fiber, improving the color and vividness of the printed pattern; high quality is preferred Commodity coniferous pulp and its ratio are increased, thereby greatly improving the stiffness of the finished paper and ensuring that the cup body is firm and thick.

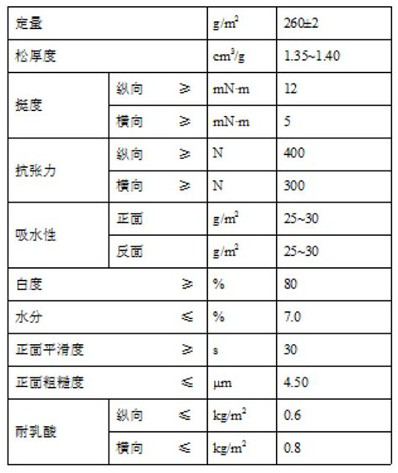

[0020] The cold chain liquid packaging paper of the present invention comprises a base paper, and a water-resistant and lactic acid-resistant sizing material arranged on the base paper, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com