Method for improving texture of high-protein yoghurt and high-protein yoghurt

A high-protein, yogurt technology, applied in milk preparations, milking equipment, bacteria used in food preparation, etc., can solve the problems of rough state, clots, caking, etc., to improve quality and taste, and improve smoothness Fineness, the effect of solving protein particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]In the preparation step of the sugar substitute component of the method of the present invention, the above fermented milk after whey separation is included and a sweetener is mixed. Wherein, the sugar substitute component may include one or more sweeteners selected from the group consisting of erythritol, xylitol, maltitol and isomalt, and optionally cream. Among them, whether or not to add cream and the amount of addition are determined by the protein content requirements of high-protein yogurt products. Preferably, the sweetener is erythritol. According to a specific embodiment, the mass ratio of the cream to the sweetener is (94-98):(6-2), preferably 95:5.

[0044] Cream is usually sterilized, eg, pasteurized at 70-75°C, before being mixed with sweeteners. The pasteurized cream is mixed with sweetener, then sterilized and cooled in the ingredient tank. At this time, the sterilization temperature is 90-95°C, and the time is 10-20min; the cooling temperature is belo...

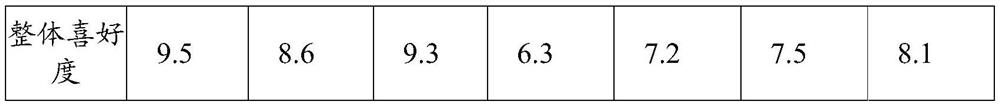

Embodiment 1

[0052] The present embodiment provides a concentrated high-protein yogurt, prepared through the following steps:

[0053] Milk fat separation: First, use a milk fat separator to separate skim milk and cream from raw milk, and then pasteurize to obtain pasteurized skim milk and pasteurized cream;

[0054] Preparation of fermented skim milk: the raw materials include pasteurized skim milk, lactase and fermented strains, based on 1000 parts of raw materials, including the following components by mass, the content of skim milk is 999.6 parts, lactase 0.4 parts, starter 100U / T (Streptococcus thermophilus 0.04U, Lactobacillus bulgaricus 0.04U, Bifidobacterium lactis 0.02U).

[0055] Cream recipes include: Pasteurized Cream, Erythritol. Based on 1000 parts of raw materials, including the following components by mass, the content of pasteurized cream is 950 parts, and the content of erythritol is 50 parts.

[0056] The concentrated high-protein yogurt is prepared by the following m...

Embodiment 2

[0063] The present embodiment provides a concentrated high-protein yogurt, prepared through the following steps:

[0064] Milk fat separation: First, use a milk fat separator to separate skim milk and cream from raw milk, and then pasteurize to obtain pasteurized skim milk and pasteurized cream;

[0065] Preparation of fermented skim milk: the raw materials include pasteurized skim milk, lactase and fermented strains, based on 1000 parts of raw materials, including the following components by mass, the content of skim milk is 999.6 parts, lactase 0.4 parts, starter 100U / T (Streptococcus thermophilus 0.04U, Lactobacillus bulgaricus 0.04U, Bifidobacterium lactis 0.02U).

[0066] Cream recipes include: Pasteurized Cream, Erythritol. Based on 1000 parts of raw materials, including the following components by mass, the content of pasteurized cream is 950 parts, and the content of erythritol is 50 parts.

[0067] The concentrated high-protein yogurt is prepared by the following m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com