A method of in-situ pyrolysis gas fluidized mining in high gassy coal seams

A technology of in-situ pyrolysis and mining method, which is applied in gas discharge, mining equipment, earthwork drilling and mining, etc., and can solve problems such as coal spontaneous combustion or gas explosion, poor controllability of catastrophe, and blockage of gas flow channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

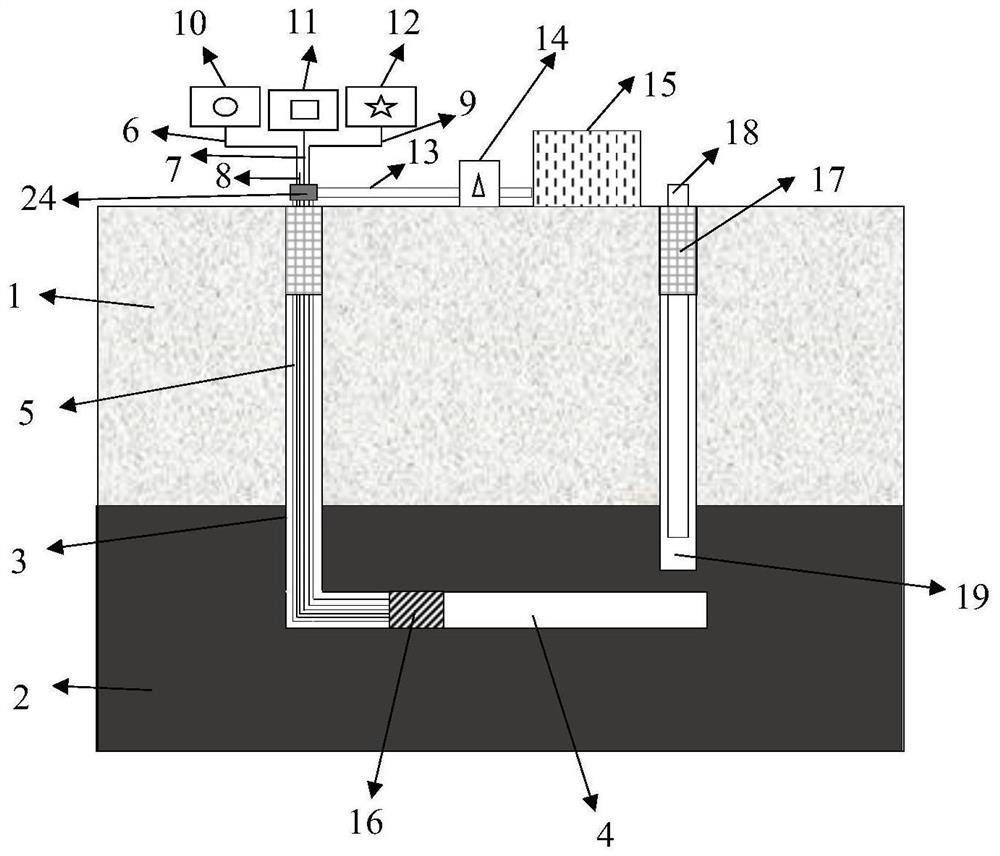

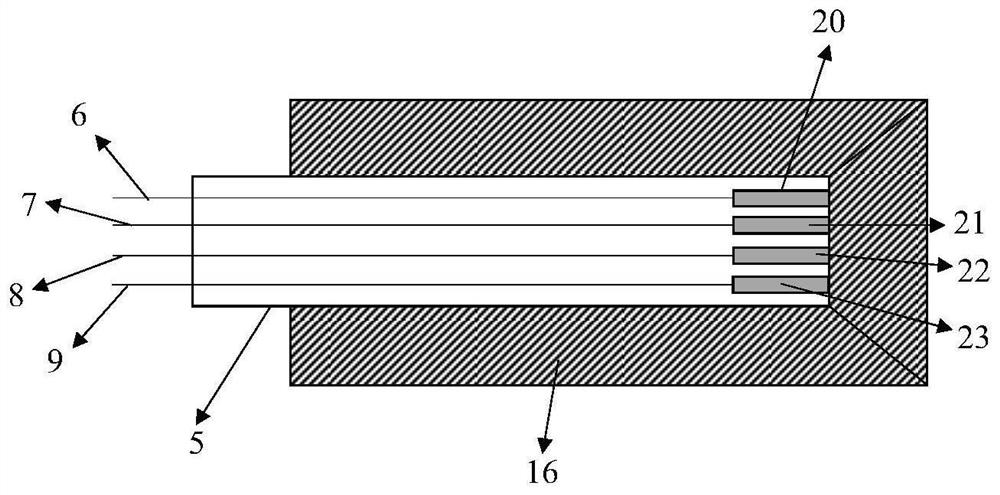

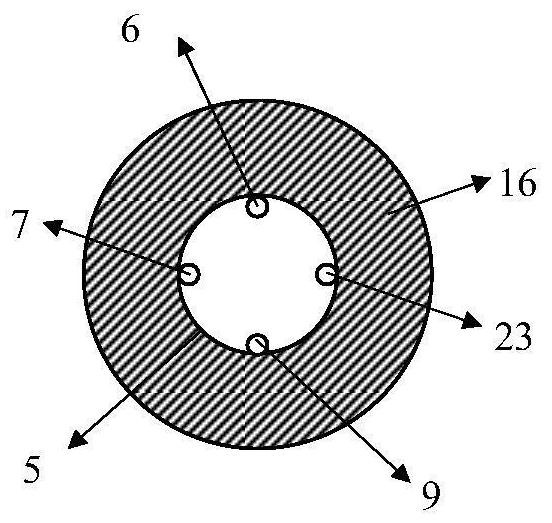

[0025] Such as figure 1 , figure 2 with image 3 As shown, the in-situ pyrolysis gas fluidization mining method of high gas coal seams of the present invention uses a multifunctional assembly device 16, and a temperature sensor 20, a gas detector 21, and a sparker head are respectively fixed in the multifunctional assembly device 16. 22 and a pressure sensor 23, the multifunctional assembly device 16 is arranged on the head of the copper tube 5, and the copper tube 5 is provided with a temperature sensor line 6, a gas detector line 7, a sparker line 8 and a pressure sensor line 9, and the copper tube 5. A temperature monitoring device 10, a multi-component gas monitoring device 11 and a pressure monitoring device 12 are provided at the tail. The other spaces in the copper pipe 5 provide air flow space. The air flow space of the copper pipe 5 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com