All-metal double-row tapered gate high-frequency structure

A high-frequency structure and all-metal technology, which is applied in the field of all-metal double-row gradient gate high-frequency structures, can solve the problems of terahertz traveling wave tubes, such as difficult output power and interaction efficiency, insufficient coupling impedance, and large transmission loss. Achieve the effects of large coupling impedance, small transmission loss, and wide operating bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

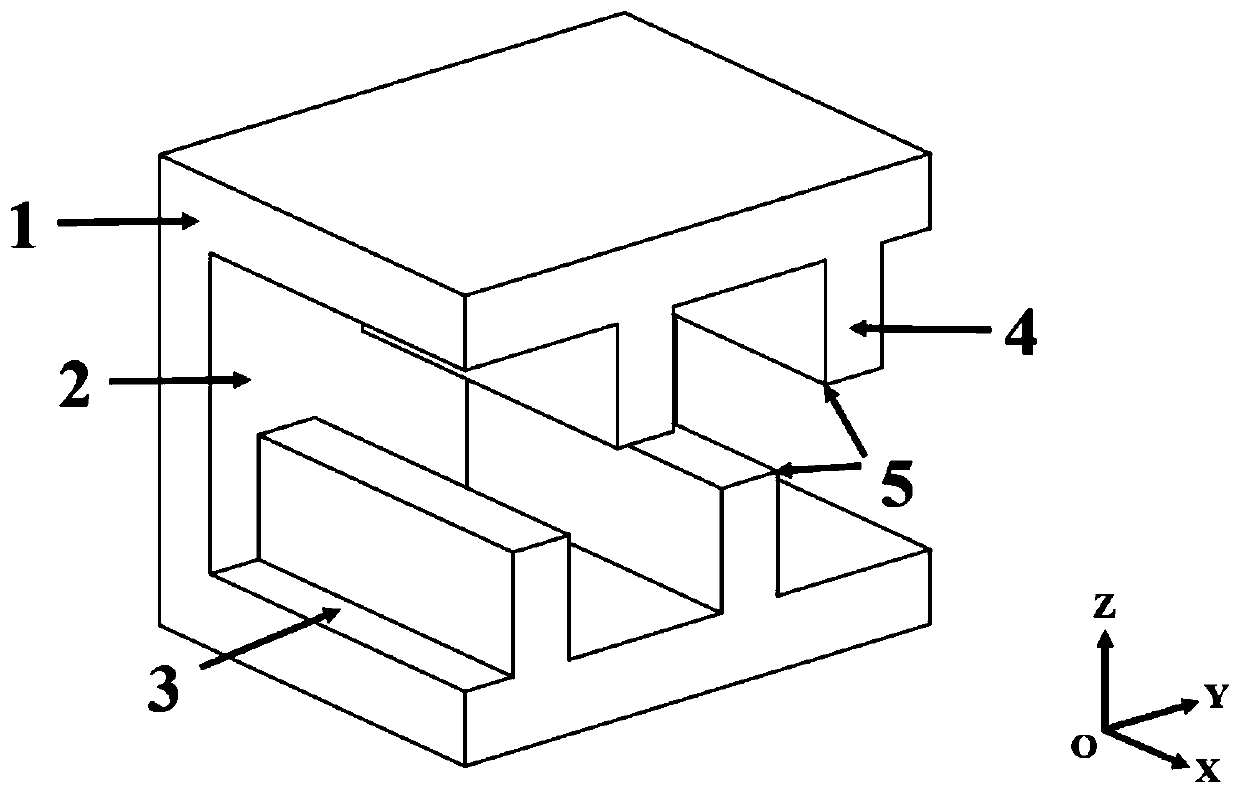

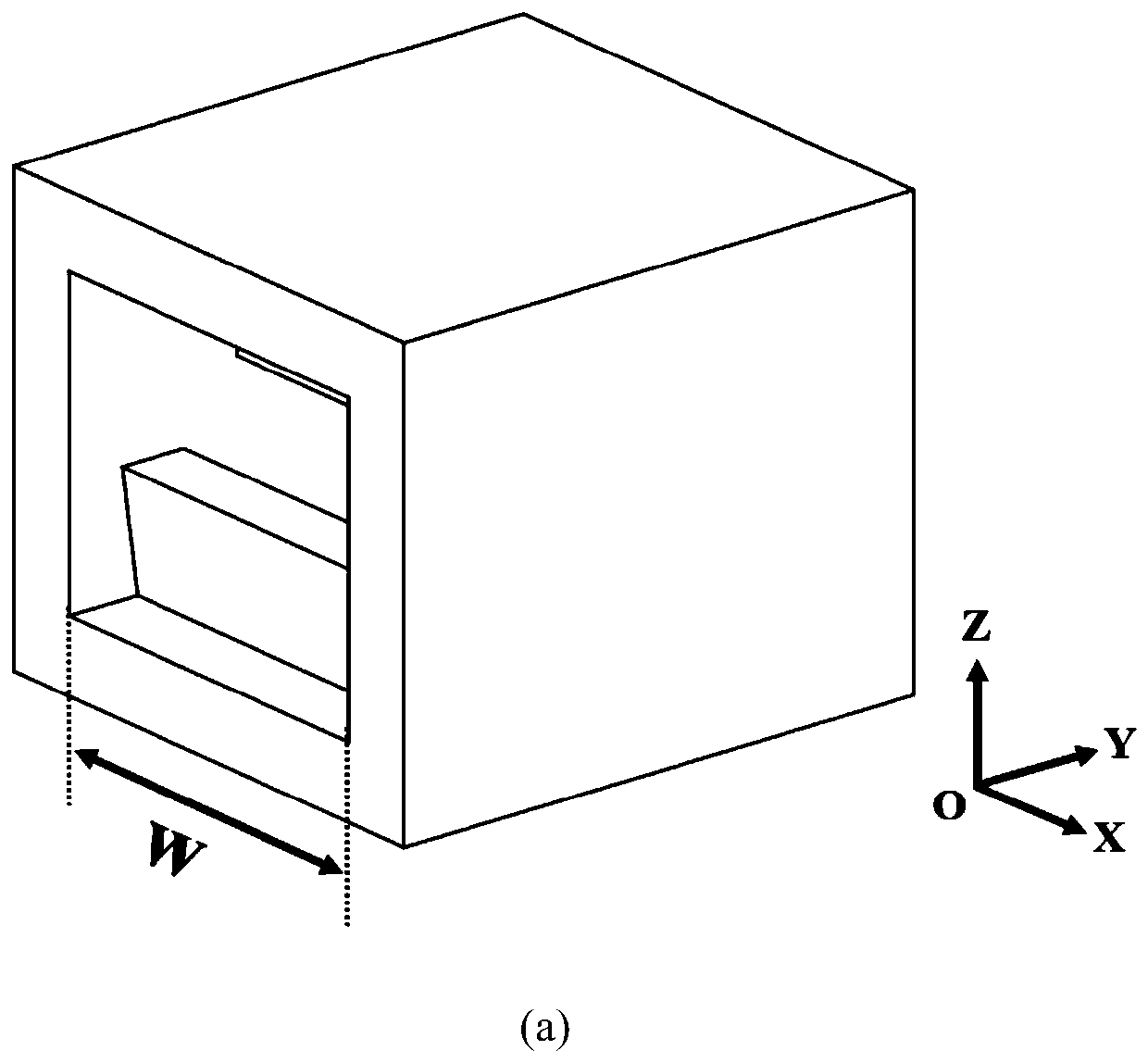

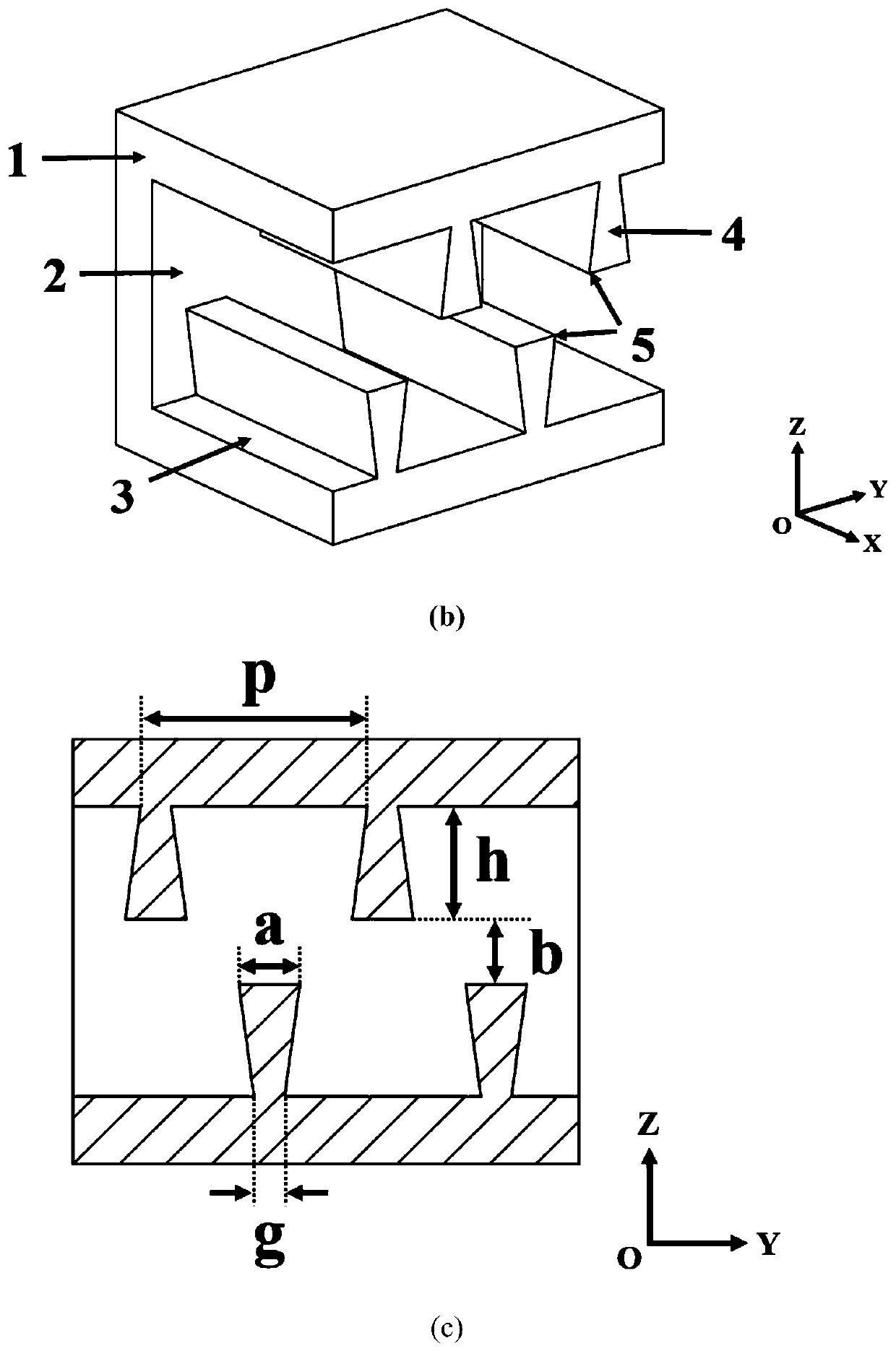

[0028] An all-metal double-row gradient gate high-frequency structure, such as figure 2 As shown, it includes a rectangular waveguide 1. The rectangular waveguide includes a wide side 3 and a narrow side 2, and grating teeth 4 arranged periodically on the inner walls of the upper and lower wide sides of the rectangular waveguide. For half a period p / 2, the vertical section of the grid teeth is an isosceles trapezoid, and the lower base of the isosceles trapezoid is set on the side close to the electron injection channel, so that the bottom angle 5 of the grid is an acute angle.

[0029] When the high-frequency structure described in this embodiment works in the frequency range of 210GHz to 230GHz, its structural size parameters are as follows: w=0.78mm, b=0.15mm, h=0.26mm, p=0.52mm, g=0.07mm, a= 0.14mm. The high-frequency structure material selected in the simulation calculation is high-conductivity oxygen-free copper.

[0030] The high-frequency characteristics and transmi...

Embodiment 2

[0032] An all-metal double-row gradient gate high-frequency structure, such as image 3As shown, it includes a rectangular waveguide 1. The rectangular waveguide includes a wide side 3 and a narrow side 2, and grating teeth 4 arranged periodically on the inner walls of the upper and lower wide sides of the rectangular waveguide. For half a period p / 2, the vertical section of the grid teeth is in the shape of a biconcave lens, the upper base and the lower base of the biconcave lens are equal, the lower base is set on the side close to the electron injection channel, and the upper and lower bases The radius of curvature of the connecting sides of the sides is r, so that the bottom corner 5 of the grid is an acute angle.

[0033] When the high-frequency structure described in this embodiment works in the frequency range of 210GHz to 230GHz, its structural size parameters are as follows: w=0.78mm, b=0.15mm, h=0.26mm, p=0.52mm, r=0.198mm, a= 0.14mm. The high-frequency structure m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com