Process method of SGT device

A process method and device technology, applied in the field of semiconductor device manufacturing, can solve problems such as large gate-source leakage, and achieve the effects of uniform thickness, increased thickness, and smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

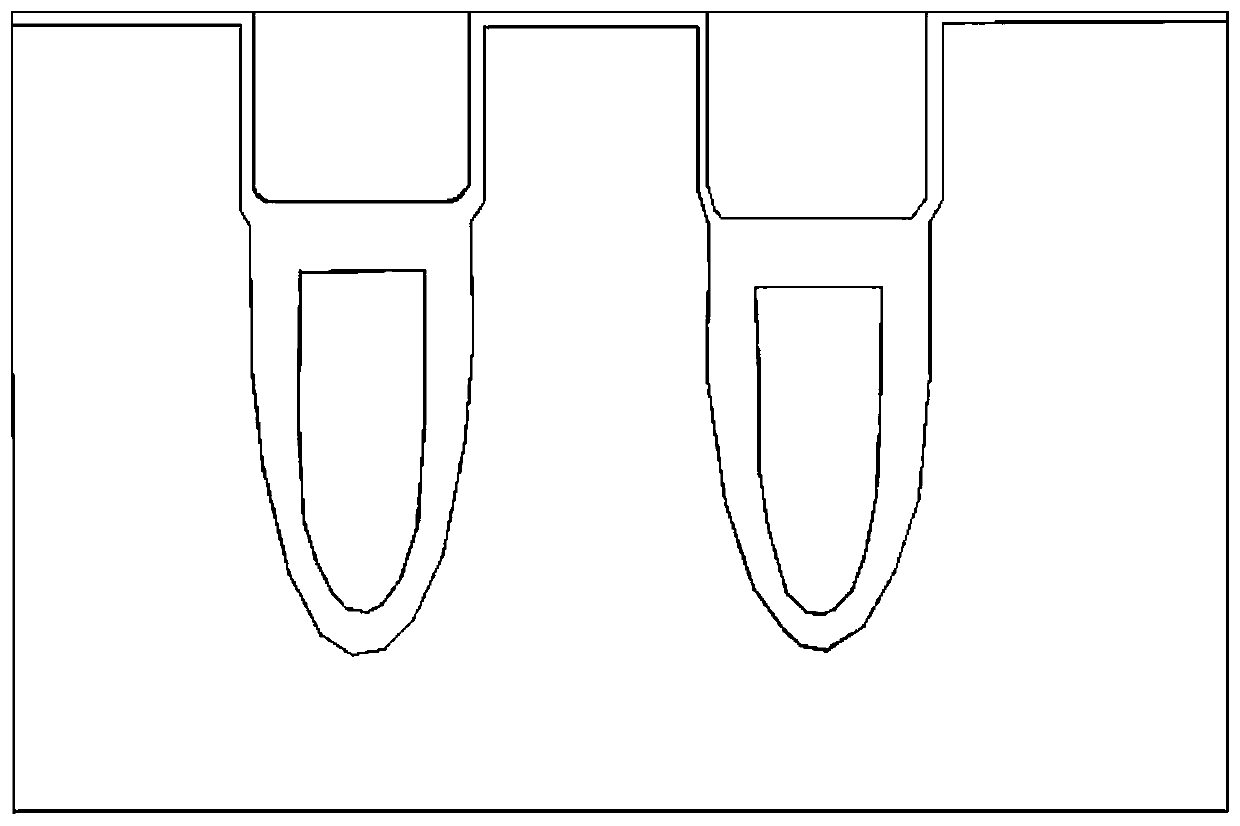

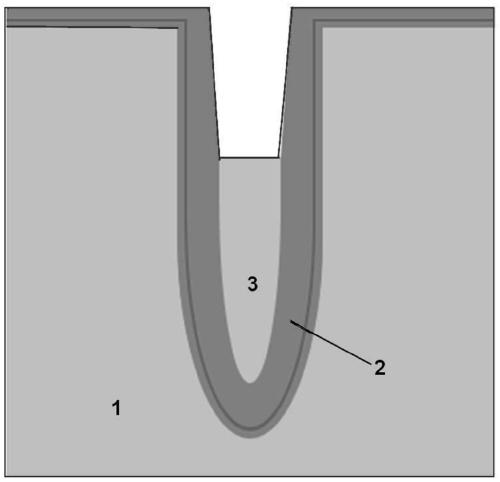

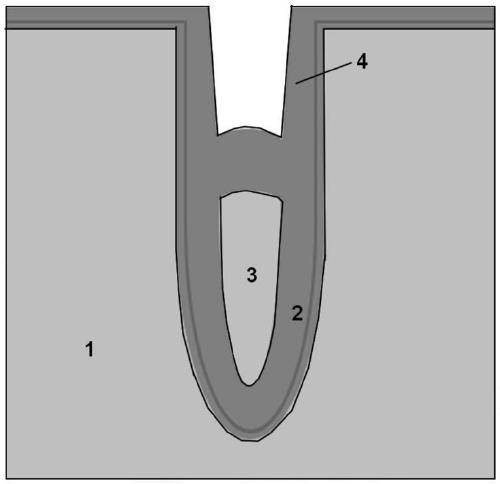

[0024] The process method of the SGT device according to the present invention is mainly aimed at forming a polysilicon source electrode and a polysilicon gate in the trench, and optimizing the morphology of its section, including the following process steps:

[0025] The first step is to form a trench gate on a heavily doped semiconductor substrate (or epitaxial). The trench gate is to form a trench on the substrate, and then deposit a dielectric layer ( The dielectric layer is a layer of silicon oxide layer close to the substrate or epitaxy on the inner wall of the trench, no reference numerals are used) and a layer of pad oxide layer, and then polysilicon is deposited and etched back to form source polysilicon, or shielding electrode polysilicon . Such as figure 2 As shown, the dielectric layer is a gate dielectric layer, such as a silicon oxide layer, and the oxide layer is attached to the inner wall of the trench as an isolation dielectric layer between the polysilicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com