Heat dissipation device based on semiconductor wafer and photovoltaic panel power station

A heat dissipation device and semiconductor technology, applied in photovoltaic power generation, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as poor heat dissipation performance and lack of temperature difference power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

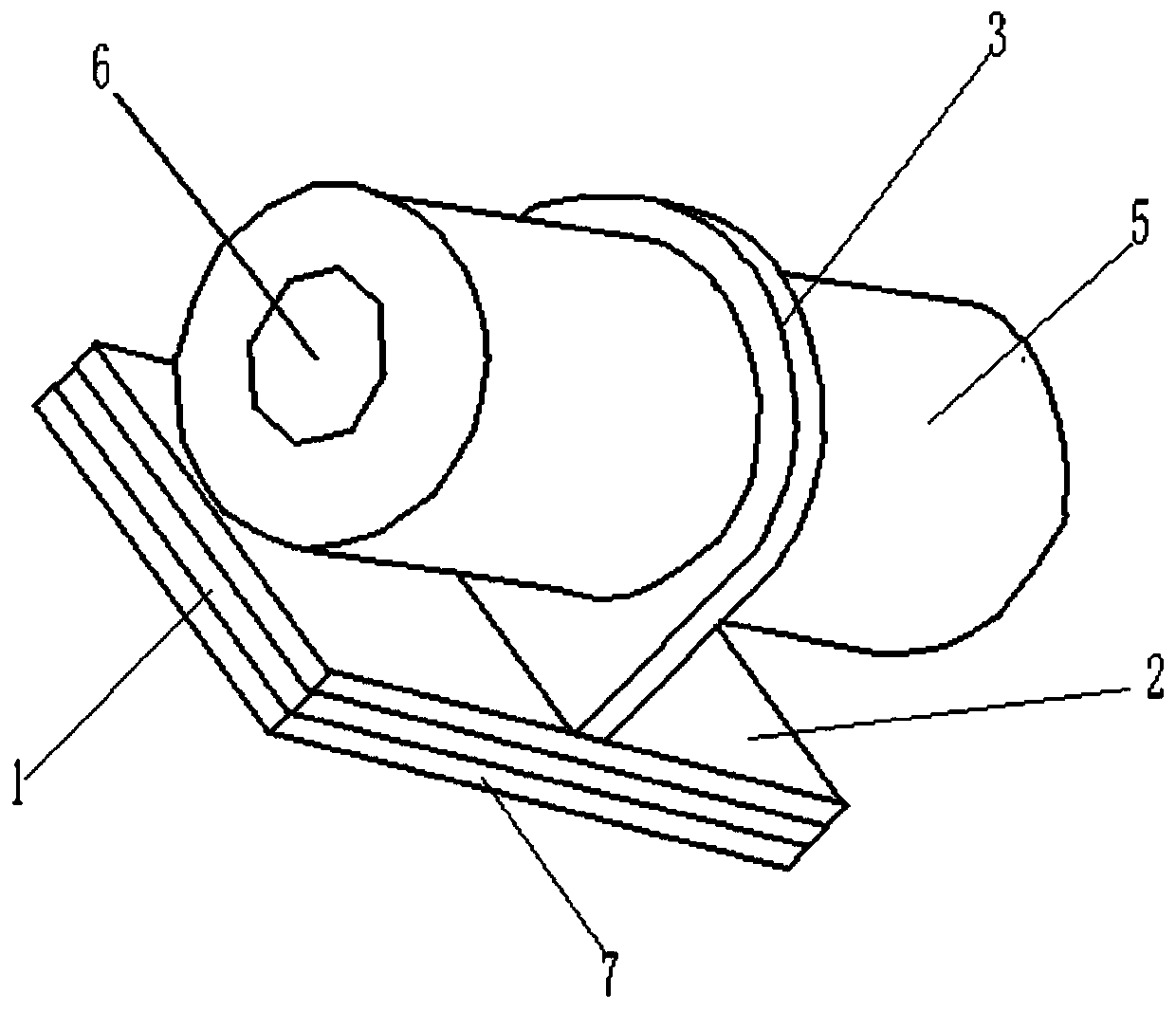

[0074] see figure 1 The heat dissipation device based on the semiconductor wafer provided by the present invention includes a semiconductor wafer 1 and at least one heat conduction component; The heat conduction plate 2, the heat conduction element 5 runs through the heat conduction rib 3, and a fluid channel 6 is formed on the heat conduction element 5;

[0075] The first end surface of the semiconductor chip 1 is attached to the heat conducting plate 2, and the second end surface of the semiconductor chip 1 is attached to the external heat sink 7; the cold fluid passes through the fluid channel 6;

[0076] Wherein, the electric arm on the first end surface of the semiconductor wafer 1 and the electric arm on the second end surface are connected to a DC power supply device, so as to realize heat transfer between the first end surface and the second end surface of the semiconductor wafer 1;

[0077] Alternatively, the electrical arm on the first end surface of the semiconduct...

no. 2 example

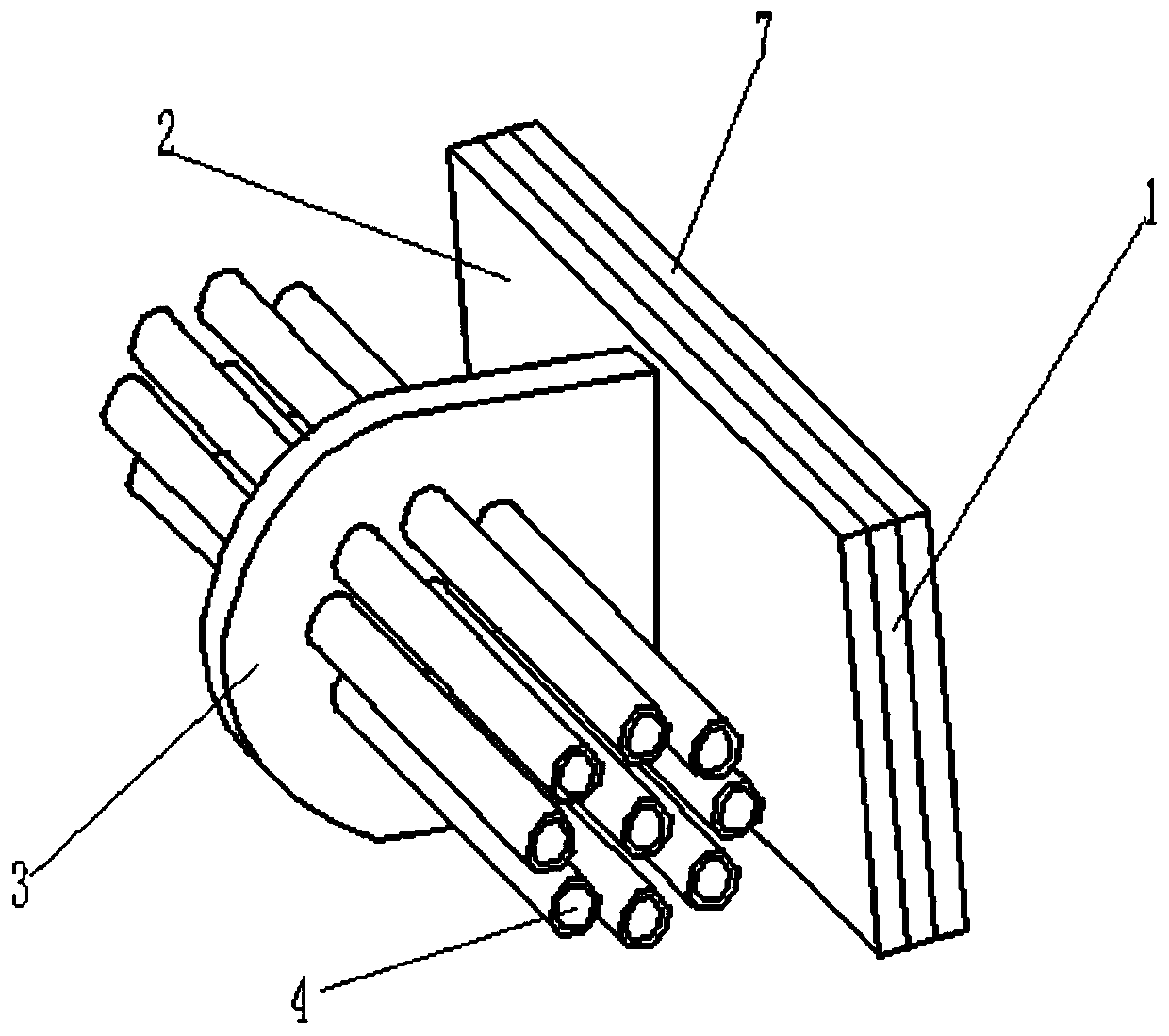

[0099] see figure 2 , based on the semiconductor wafer-based heat dissipation device proposed in the first implementation of the present invention, the second embodiment of the present invention proposes another heat dissipation device, the difference is that the number of the conduction and heat transfer elements 4 is Multiple, the conduction and heat transfer elements 4 are guide tubes.

no. 3 example

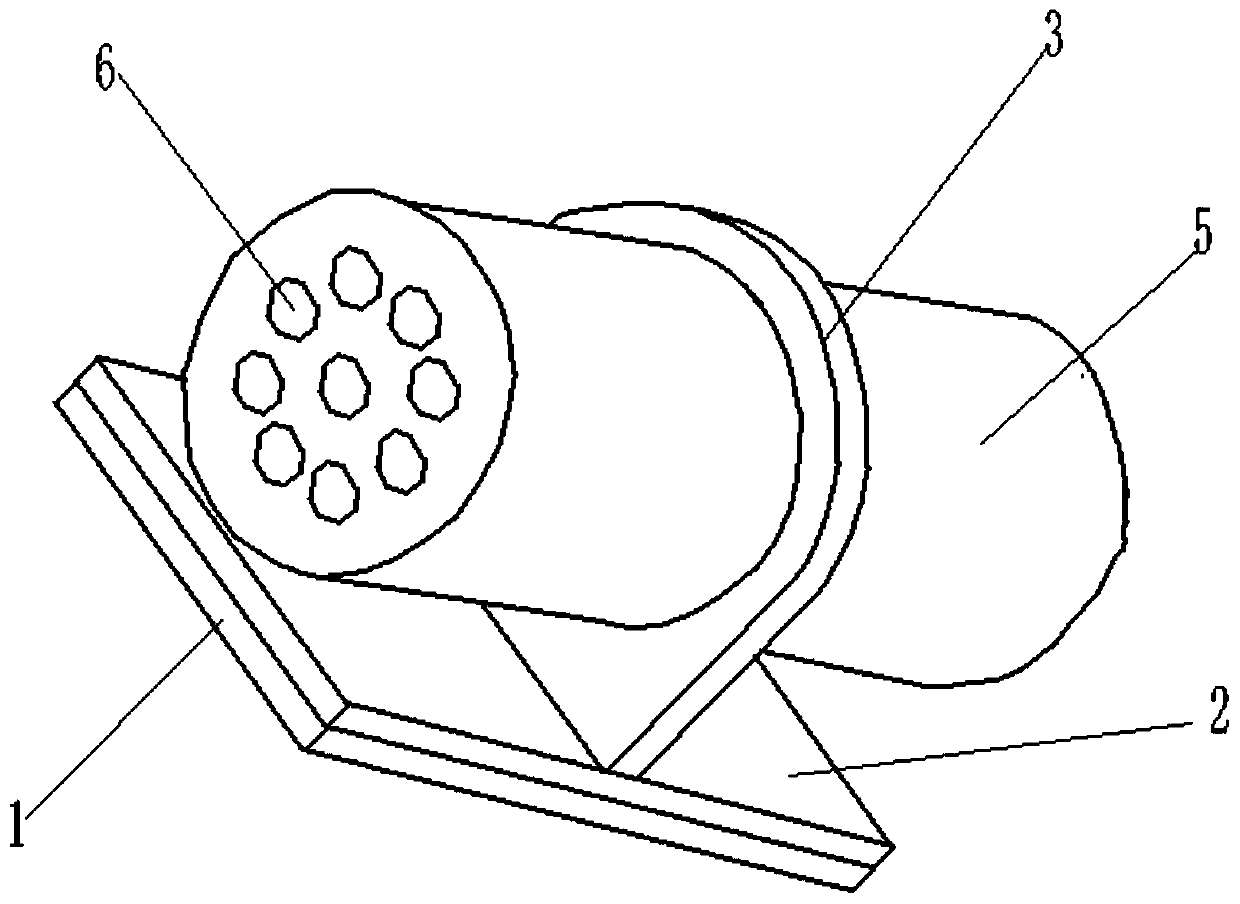

[0101] see image 3 , based on a heat dissipation device based on a semiconductor wafer proposed in the first implementation of the present invention, the third embodiment of the present invention proposes another heat dissipation device, the difference is that the number of the conduction and heat transfer elements 5 is One, the conduction and heat transfer element 5 is a guide post; the guide post is a porous guide post.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com