Coupling boiler applied to supercritical carbon dioxide and thermoelectric power generation

A carbon dioxide and thermoelectric power generation technology, applied in generators/motors, electrical components, steam generation, etc., can solve problems such as heat loss, greenhouse effect, energy waste, etc., and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

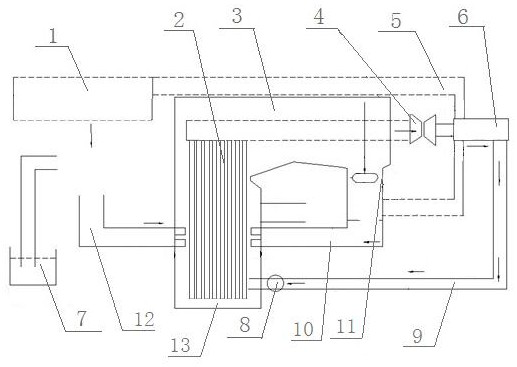

[0015] A coupling boiler applied to supercritical carbon dioxide and thermoelectric power generation, which consists of a supercritical carbon dioxide furnace 13, a steam turbine 4, a pulverized-coal furnace horizontal flue outlet 1 and a heat exchange temperature rise tube 6, the level of the supercritical carbon dioxide furnace The flue is respectively communicated with the steam turbine and the CO gas pipeline 10, the steam turbine is communicated with the heat exchange temperature rise tube, the high-temperature tail gas at the outlet of the horizontal flue of the pulverized coal boiler and the gas of the horizontal flue are The high-temperature tail gas in the flue reduction section is respectively bridged with the low-temperature tail gas passing through the steam turbine through the thermoelectric power generation sheet group 5, and the heat exchange and temperature rise tube is connected to the CO2 gas cooling of the supercritical carbon dioxide furnace through a pressur...

Embodiment 2

[0017] According to the coupling boiler applied to supercritical carbon dioxide and thermoelectric power generation described in Embodiment 1, the outlet of the horizontal flue of the pulverized coal boiler communicates with the CO channel 12 .

Embodiment 3

[0019] According to the coupling boiler applied to supercritical carbon dioxide and thermoelectric power generation described in embodiment 1 or 2, the outlet of the horizontal flue of the pulverized coal boiler is connected with the absorption pool 7 through pipelines.

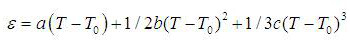

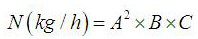

[0020] The thermoelectric power generation method is to use the thermoelectric power generation sheet group to bridge the high-temperature exhaust gas of the pulverized coal boiler and the low-temperature exhaust gas of the supercritical carbon dioxide circulating furnace, and the thermoelectric power generation sheet used is bismuth antimonide Bi 2 Te 3 , the high-temperature flue gas temperature T of the pulverized coal furnace is 160°C, and the supercritical carbon dioxide working medium parameter after temperature control and pressure control (heat conduction and pressure reduction) is T 0 =31.1°C, P=7.38MPa. According to Seebeck's law, for Bi 2 Te 3 As far as the thermoelectric power generation chip i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com