LNG cold energy temperature difference power generation system based on seawater gasifier

A gasifier and seawater technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of inconvenient operation and maintenance of equipment, complex system equipment, restrictions on application and promotion, etc., so as to improve energy utilization efficiency, high power generation efficiency, reduce The effect of small thermal contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are listed hereby, and are described in detail in conjunction with the accompanying drawings:

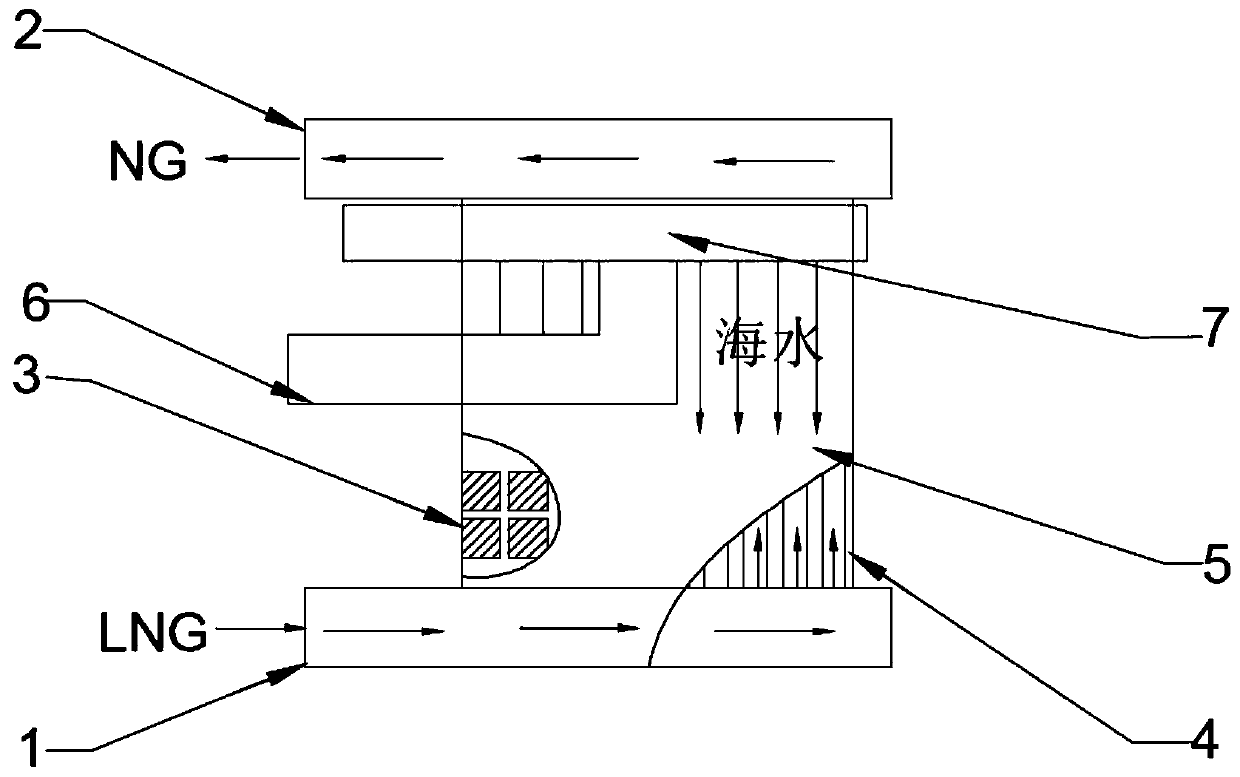

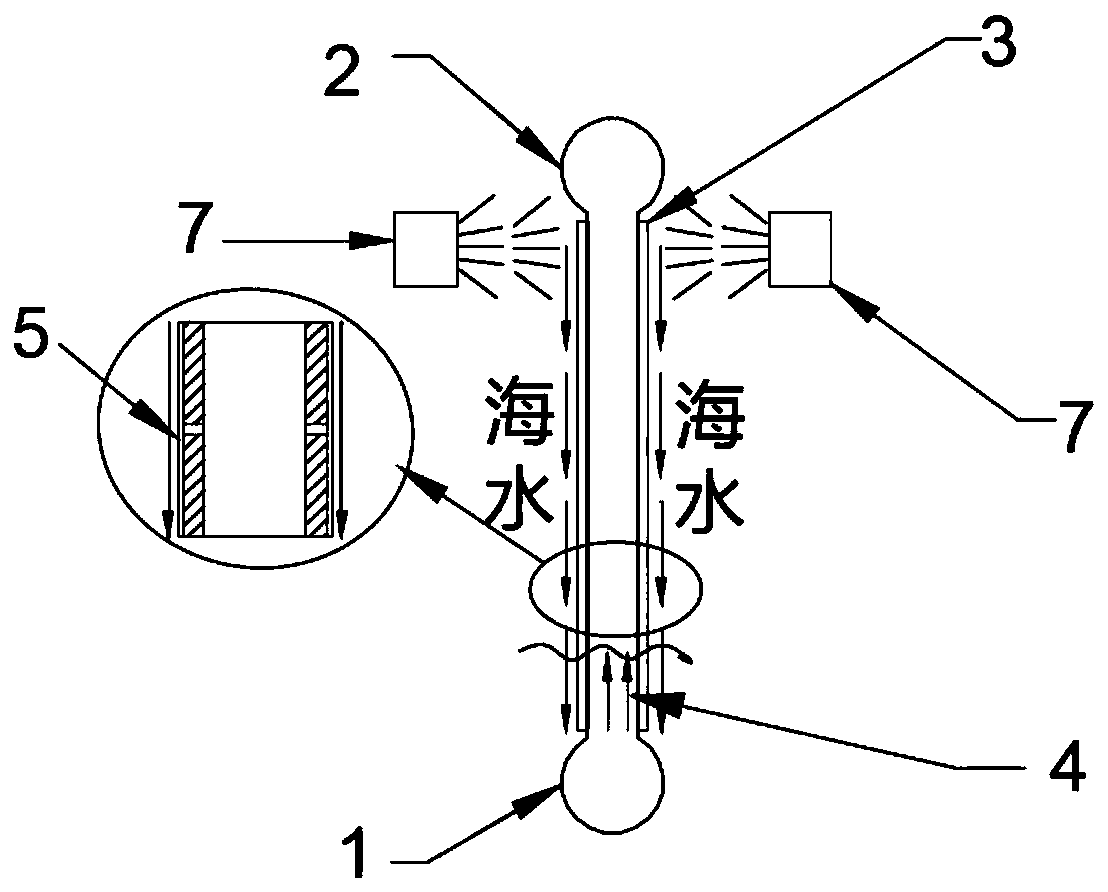

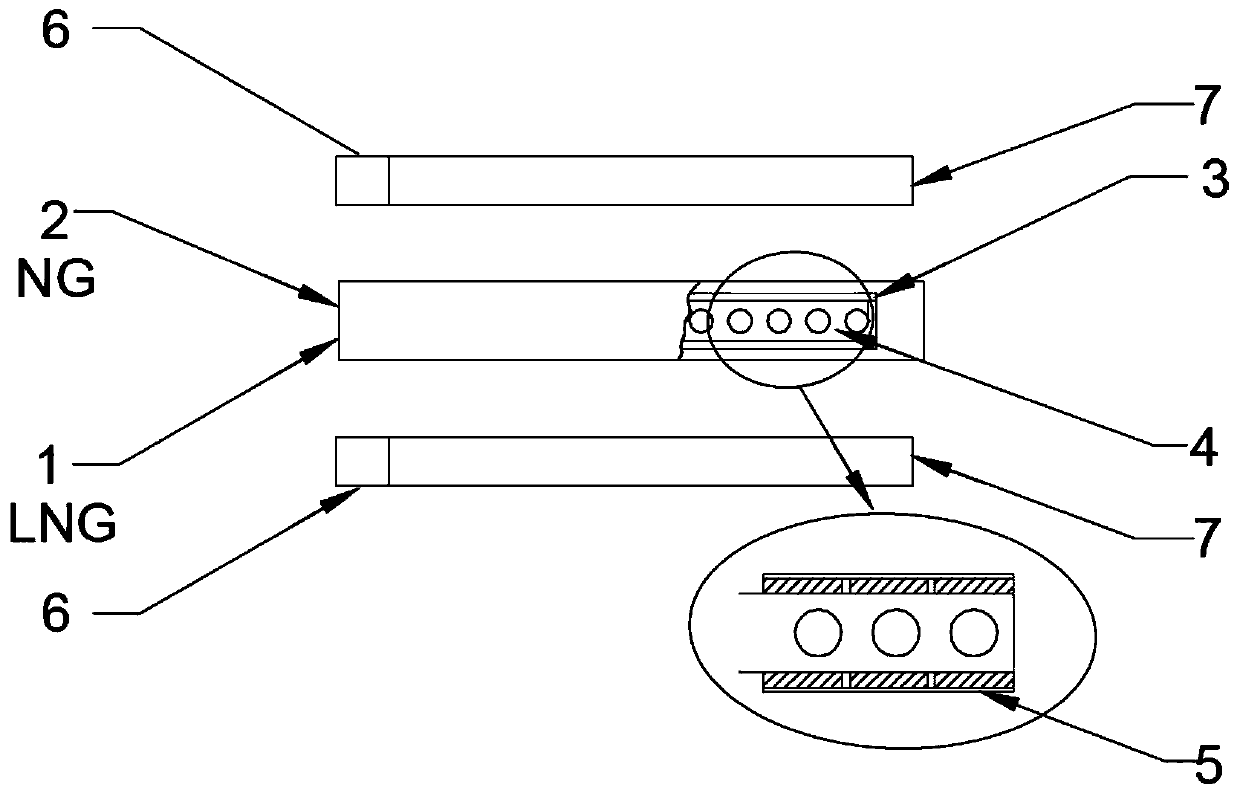

[0022] Such as Figure 1-3 As shown, the LNG cold energy thermoelectric power generation system based on seawater vaporizer of the present invention consists of LNG inlet pipe 1, natural gas outlet pipe 2, thermoelectric module 3, heat transfer tube bundle 4, equal temperature plate 5, seawater inlet pipe 6, seawater spray Device 7 is composed. The LNG inlet pipe 1 is connected to the bottom of the heat transfer tube bundle 4 , and the natural gas outlet pipe 2 is connected to the top of the heat transfer tube bundle 4 . The outer surface of the heat transfer tube bundle 4 is paved with a thermoelectric module 3 and a vapor chamber 5 in sequence, and the three can be fastened with bolts, and carbon paper is paved on both sides of the thermoelectric modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com