Power module packaging structure and packaging method thereof

A packaging structure and power module technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problem of small space for reducing inductance, and achieve the effects of reducing overshoot voltage, reducing switching oscillation, and improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing.

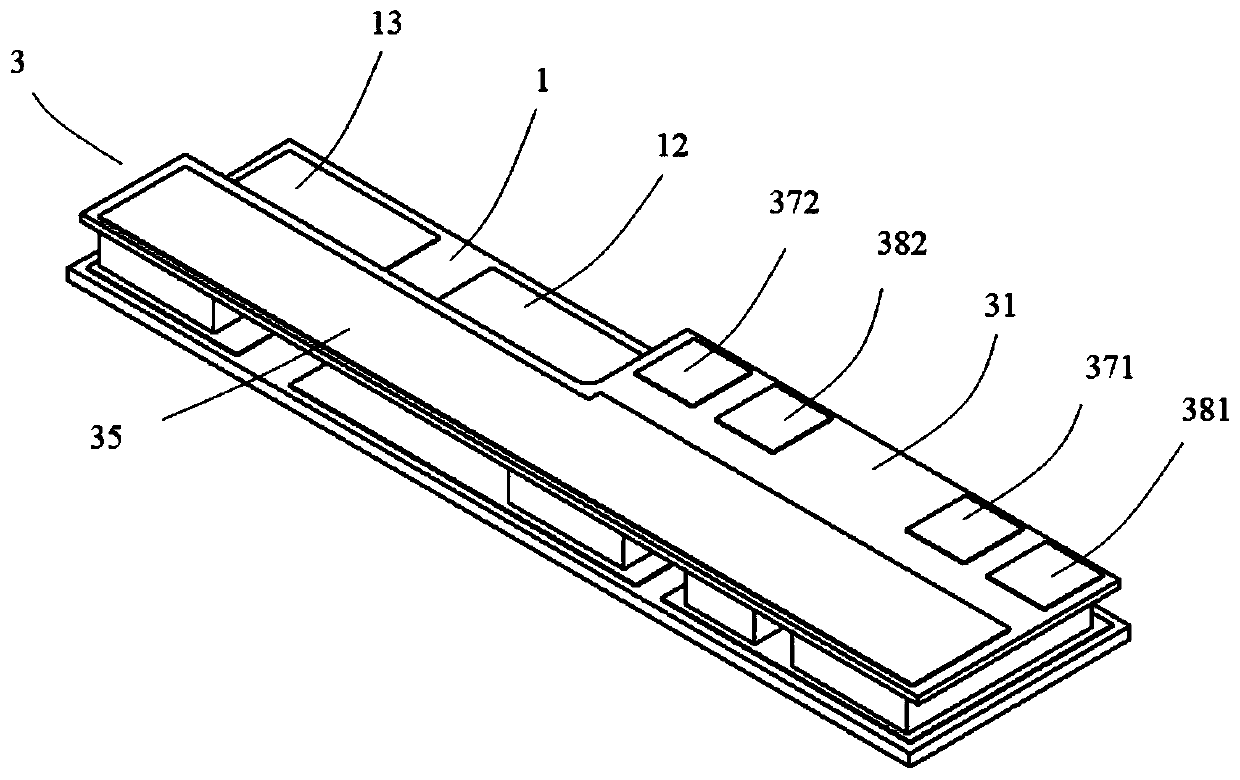

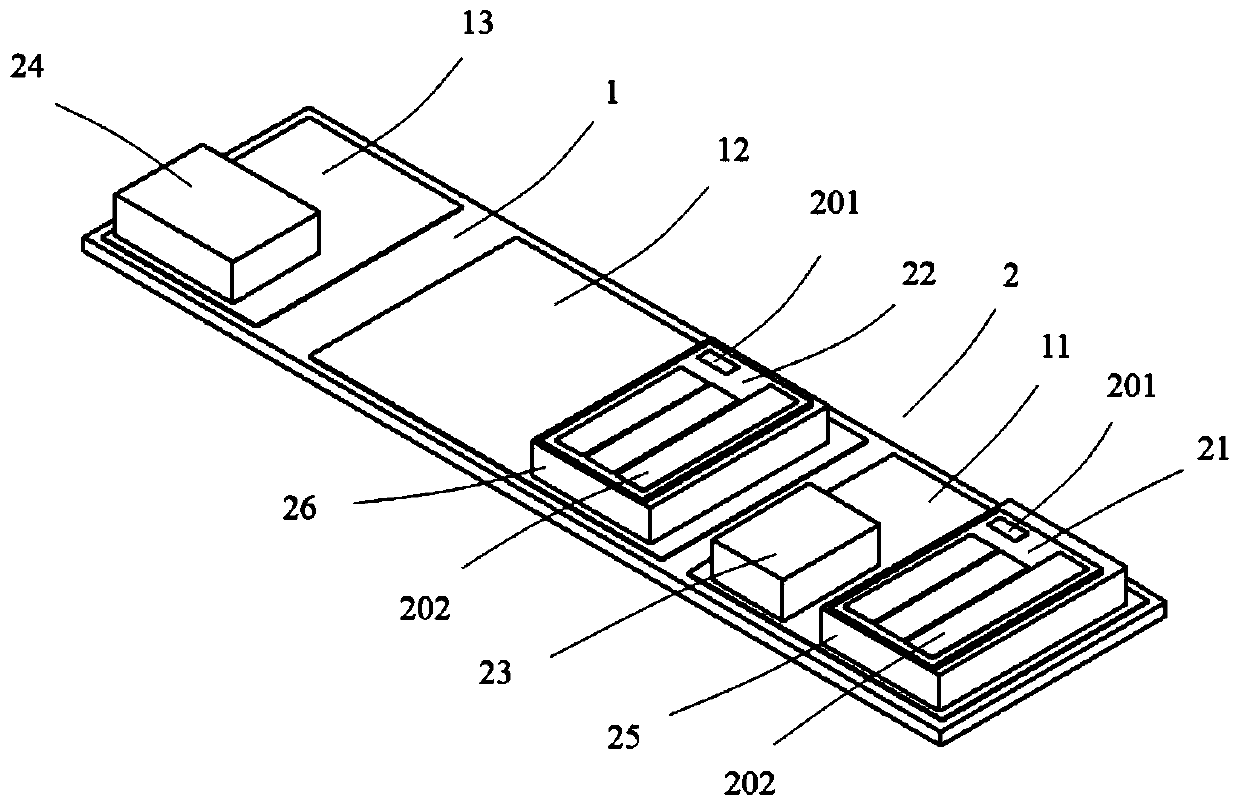

[0045] as attached figure 1 As shown, the power module packaging structure provided by the present invention includes a backing board 1, on which a module functional unit is arranged, and the upper surface of the module function unit is covered with a circuit board 3, and the circuit board 3 is used for bonding the backing board 1 and the module. functional unit.

[0046] Specifically, the circuit board 3 replaces the traditional bonding wires, together with the backing board 1 and the module functional unit, constitutes a current transmission loop for main current and control signals. as attached figure 1 As shown, the structure of the entire power module without bonding wires eliminates the need to reserve the position of bonding wires on the metal layer in the module, and does not need to consider the size of the bonding wires and whether it is convenient for the bondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com