Biconcave metal semiconductor resonant cavity for nano laser

A metal semiconductor and nano-laser technology, applied in the structure of optical resonators, lasers, laser parts, etc., can solve the problems of large radiation loss, large metal loss, mode dispersion, etc., to reduce radiation loss, easy to manufacture, reduce Effect of Threshold Current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

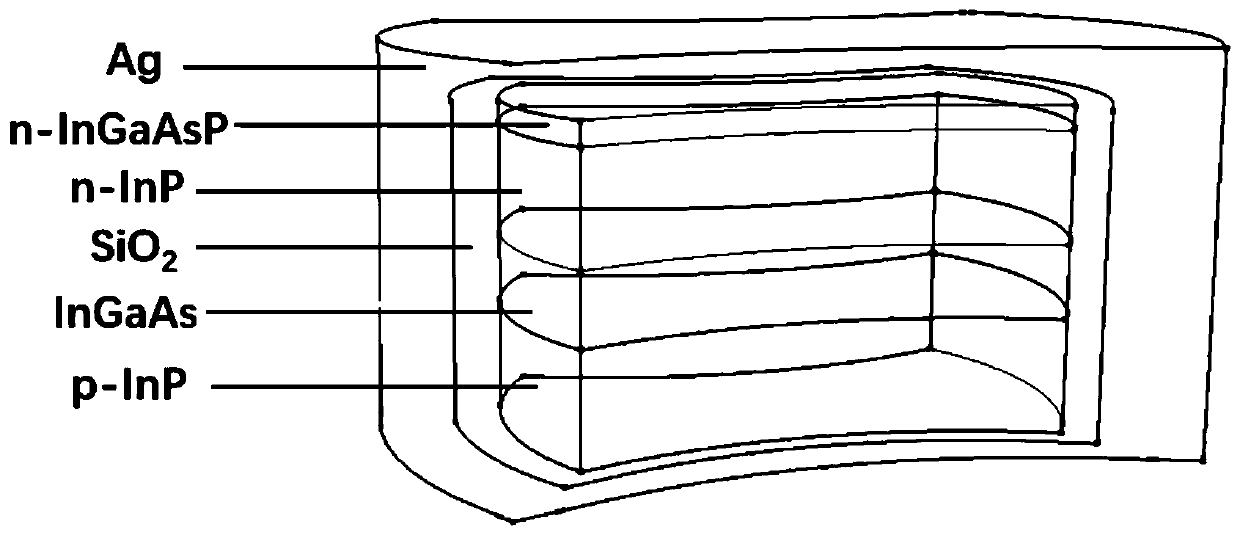

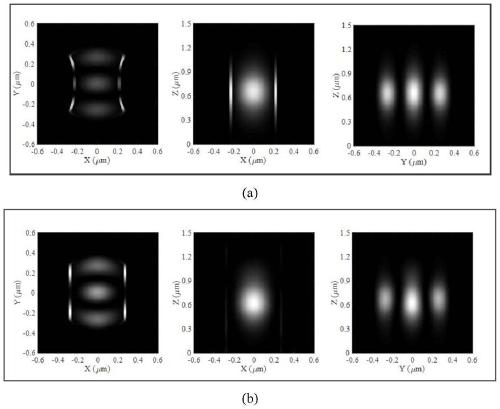

[0030] figure 1 It is a three-dimensional schematic diagram of a double-concave metal-semiconductor resonator for nano-lasers in this embodiment. The curved sidewall shape of the sidewall of the metal-semiconductor resonator is suitable for any concave curve. The cubic function resonator in this embodiment has a curved sidewall. The curve is:

[0031] y=a x 3 +W 0 / 2

[0032] Among them, y represents the width of the side wall curve in the y direction, which changes with the coordinate x, a represents the degree of curvature of the side wall curve in the concave curve, W 0 Indicates the beam waist width of the concave curve of the resonator.

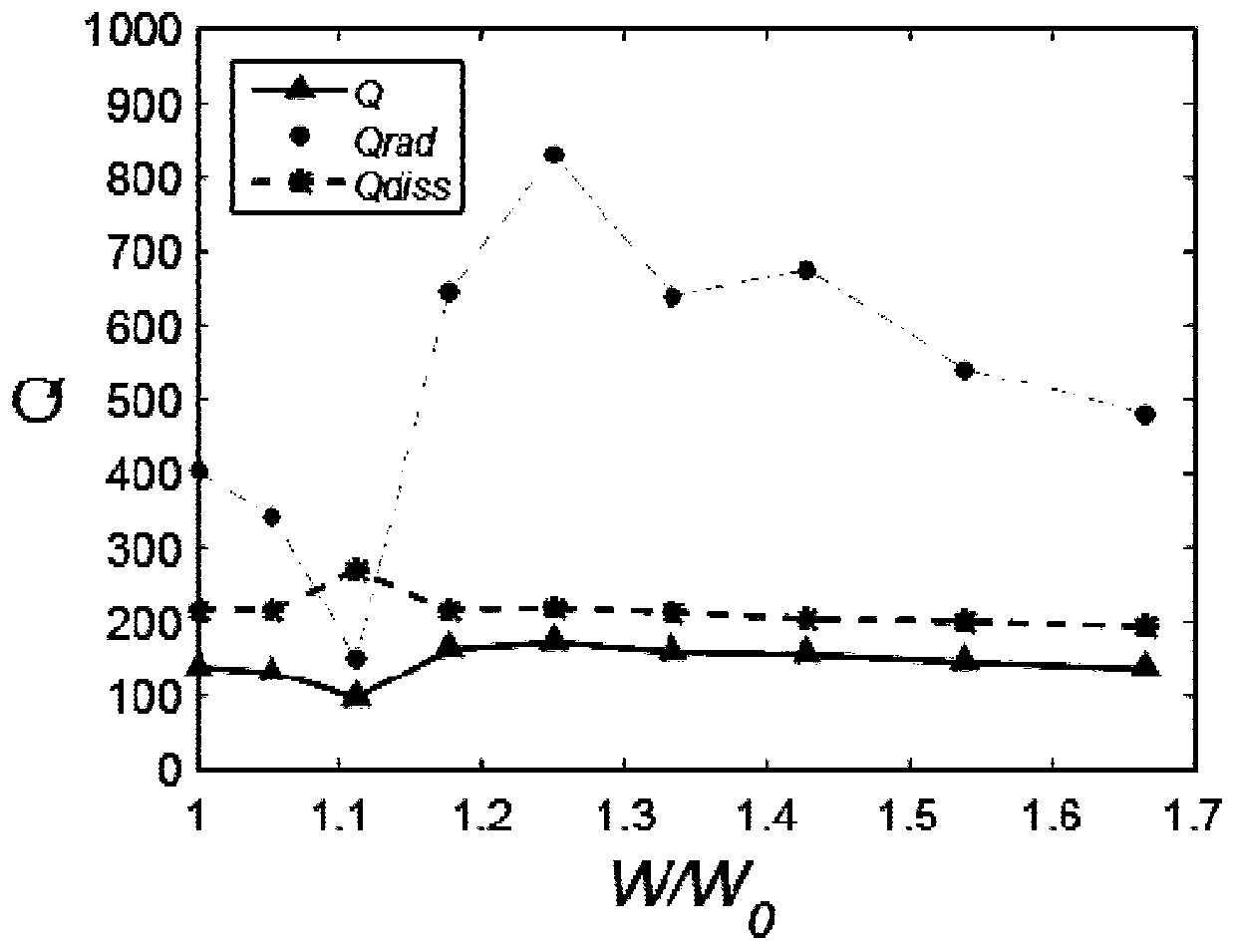

[0033] Taking the cubic function curve as an example, the given function constitutes a double-concave side wall concave curve, the cavity length of the resonant cavity is L=700nm, the maximum width of the resonant cavity is W=520nm, and the beam waist width of the concave curve of the resonant cavity is W 0 =0.8W, L / R=1.43. The sem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cavity length | aaaaa | aaaaa |

| Maximum width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com