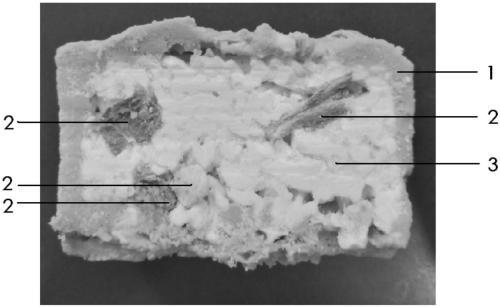

Non-fried instant noodles with core-wrapped structure and preparation method thereof

A technology for non-fried instant noodles and core wrapping, which is applied in food science and other directions, can solve the problems of brittleness of freeze-dried vegetable pieces, and achieve the effect of convenient eating, convenient processing and eating, and the best state and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The raw materials for preparing noodles provided by the invention include 60-120 parts by mass of high-strength flour, preferably 70-110 parts by mass, more preferably 80-100 parts by mass.

[0056] The raw materials for preparing noodles provided by the present invention further include 20-35 parts by mass of modified starch, preferably 23-32 parts by mass, more preferably 26-29 parts by mass. The modified starch is preferably tapioca hydroxypropyl distarch phosphate starch and / or potato acetate starch.

[0057] The raw materials for preparing noodles provided by the present invention further include 1-5 parts by mass of gluten powder, preferably 2-4 parts by mass, more preferably 2.5-3.5 parts by mass.

[0058] The raw materials for preparing noodles provided by the present invention further include 1-1.5 parts by mass of salt, preferably 1.1-1.4 parts by mass, more preferably 1.2-1.3 parts by mass.

[0059] The raw materials for preparing noodles provided by the pre...

Embodiment 1

[0124] The preparation method of the non-fried instant noodles with core-wrapped structure of the present embodiment is carried out according to the following steps:

[0125] (1) Weigh high-gluten flour 100g, hydroxypropyl distarch phosphate starch 25g, gluten powder 2.5g, salt 1.5g, egg liquid 1.5g, xanthan gum 0.1g, sodium dihydrogen phosphate 0.15g, lecithin 0.15g, gardenia yellow: 0.08g

[0126] (2) Dissolve the above-mentioned materials except flour, gluten and starch with 48ml of water, add egg liquid, stir at a speed of 40 rpm for more than 40 minutes, and make a saline solution for later use;

[0127] (3) Add flour, starch and gluten into the vacuum dough kneading machine, evacuate until the vacuum degree reaches 0.06Mpa, add the salt water prepared in (2) into the vacuum kneading pot, and stir at a speed of 80r / min 10 minutes, until a uniform flocculent is formed, and ripen for 20 minutes.

[0128] (4) Press the noodle strip into a noodle strip with a thickness of 1...

Embodiment 2

[0142] The preparation method of the non-fried instant noodles with core-wrapped structure of the present embodiment is carried out according to the following steps:

[0143] (1) Weigh 100g of high-gluten flour, 25g of potato acetate starch, 2g of gluten powder, 2g of salt, 2g of egg liquid, 0.1g of guar gum, 0.15g of sodium hexametaphosphate, 0.15g of sucrose fatty acid ester, turmeric 0.08g;

[0144] (2) Dissolve the above-mentioned materials except flour, gluten and starch with 46ml of water, add egg liquid, stir at a rate of 40 rpm for more than 40 minutes, and make a saline solution for later use;

[0145] (3) Add flour, starch and gluten into the vacuum dough kneading machine, evacuate until the vacuum degree reaches 0.06Mpa, add the salt water prepared in step (2) into the vacuum kneading pot at a speed of 80r / min Stir for 10 minutes until a uniform flocculent is formed, and ripen for 20 minutes.

[0146](4) Press the noodle strip into a noodle strip with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com