Plastic color master batch production equipment

A technology of production equipment and color masterbatch, which is applied in the direction of grain processing, etc., can solve the problems of high cost and machine wear, and achieve the effect of reducing grinding process, reducing waste and eliminating irritating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

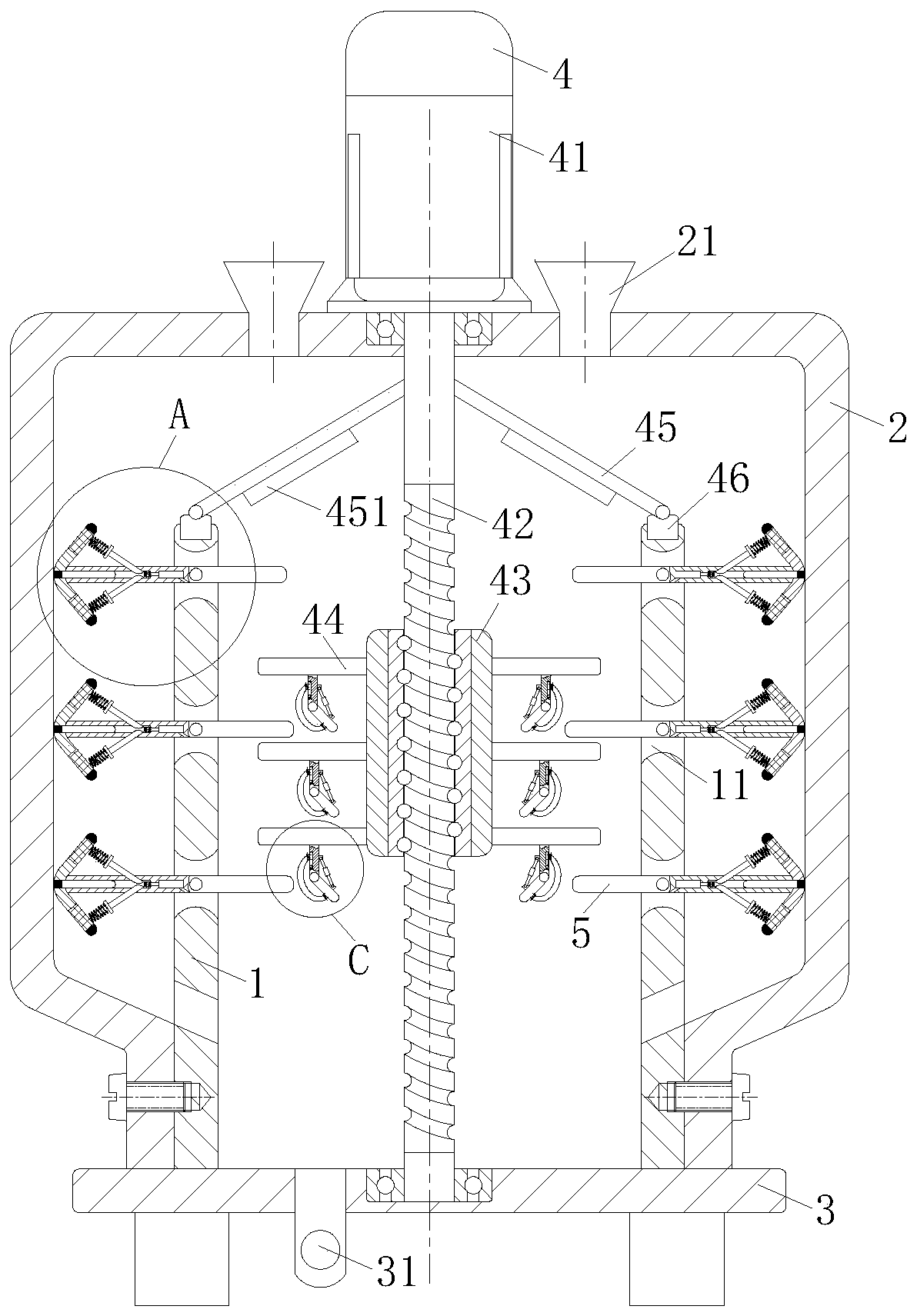

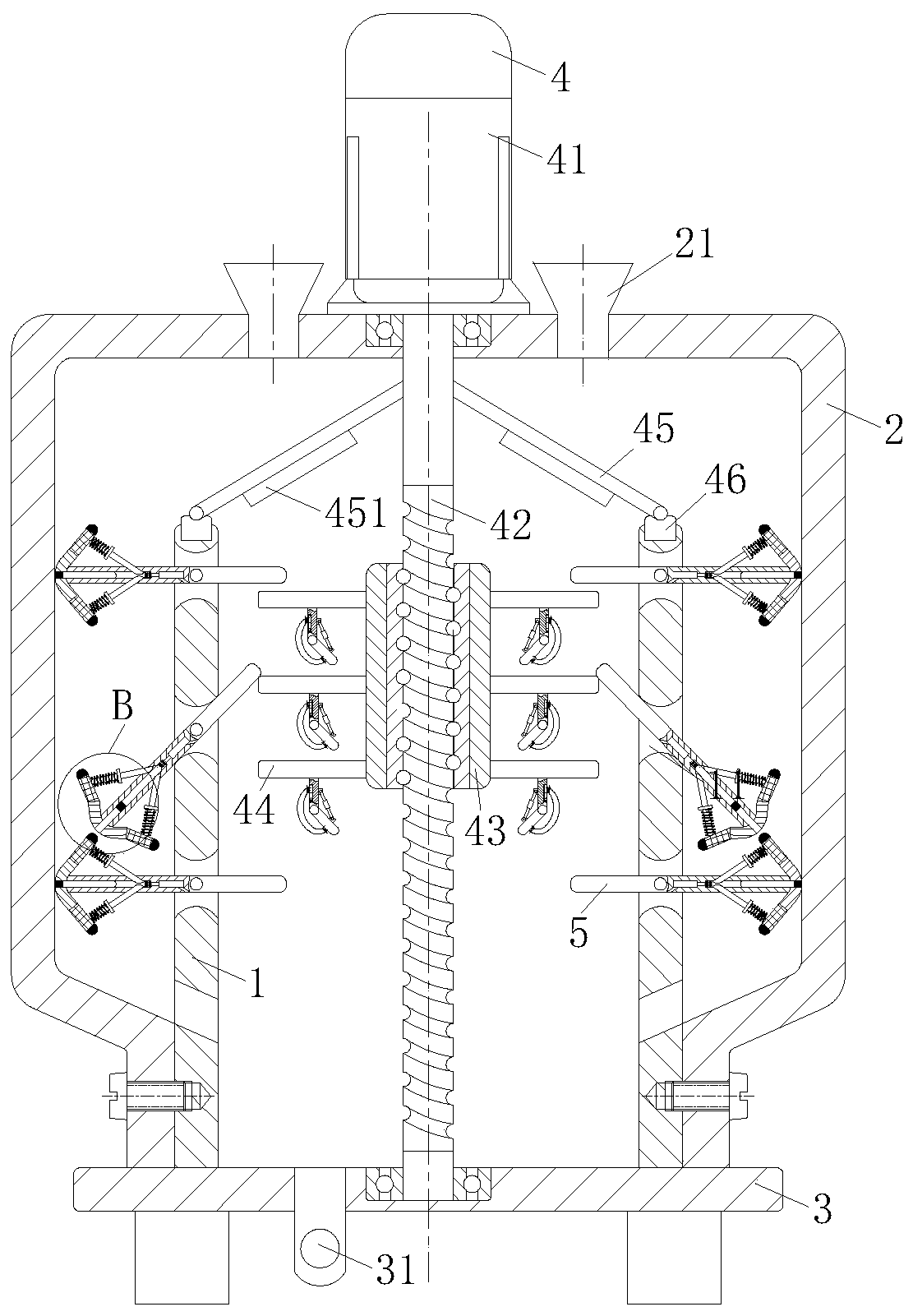

[0030] As a specific embodiment of the present invention, an ultraviolet lamp 451 is provided on the lower surface of the mounting plate 45, and the irritating gas in triphenyl phosphite is further eliminated by the rotating ultraviolet lamp 451; by setting the ultraviolet lamp 451 , the ultraviolet lamp 451 rotates with the rotation of the mounting plate 45 to further eliminate the pungent smell in the triphenyl phosphite and improve its elimination effect, thereby improving the production of the operators who produce its plastic color masterbatch environment.

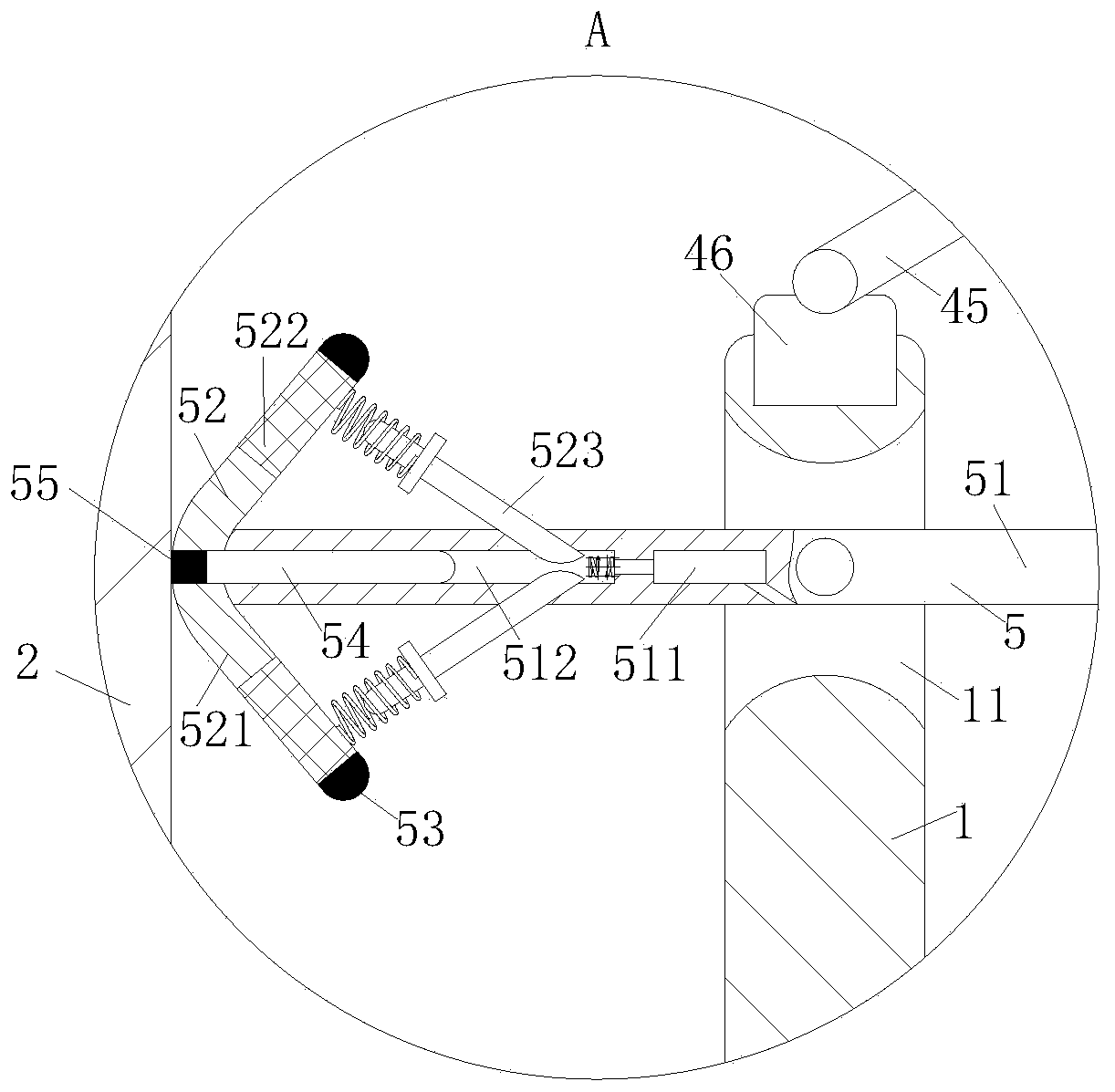

[0031]As a specific embodiment of the present invention, the pressure grinding block 52 is composed of a No. 1 grinding block 521 and an elastic No. 2 grinding block 522; one side of the pendulum plate 51 is symmetrically provided with a through groove, and a There is a push rod 523, one end of the push rod 523 is located in the No. 1 channel 512, and the other end is in contact with the No. Spring; through the effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com