Buffering tray for solvent-free paper-plastic lamination or cigarette packet transferring technology and operation method

A technology of paper-plastic composite and operation method, which is applied in the directions of packaging, transportation and packaging, and containers for preventing mechanical damage. Avoid stress concentration and facilitate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

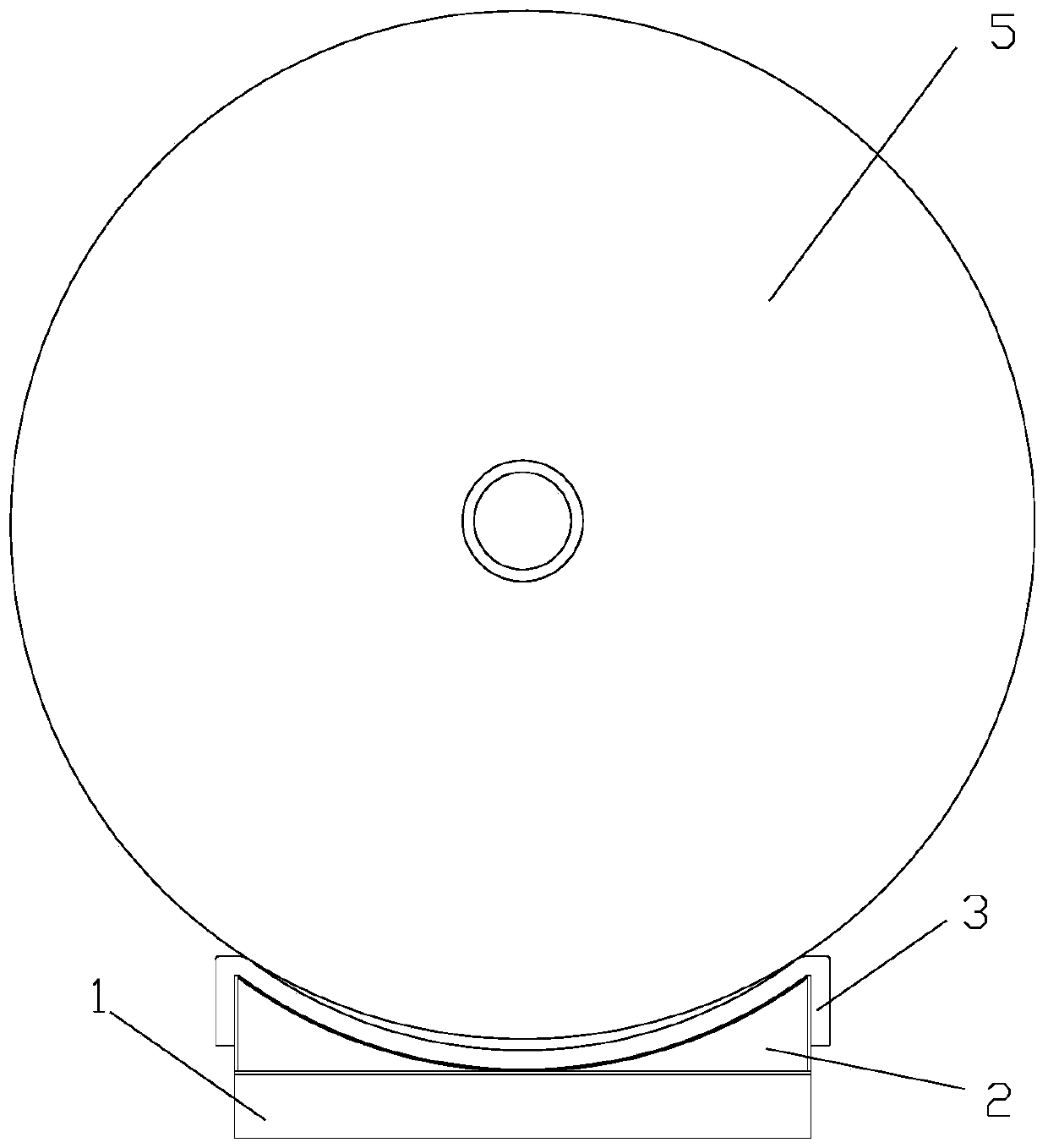

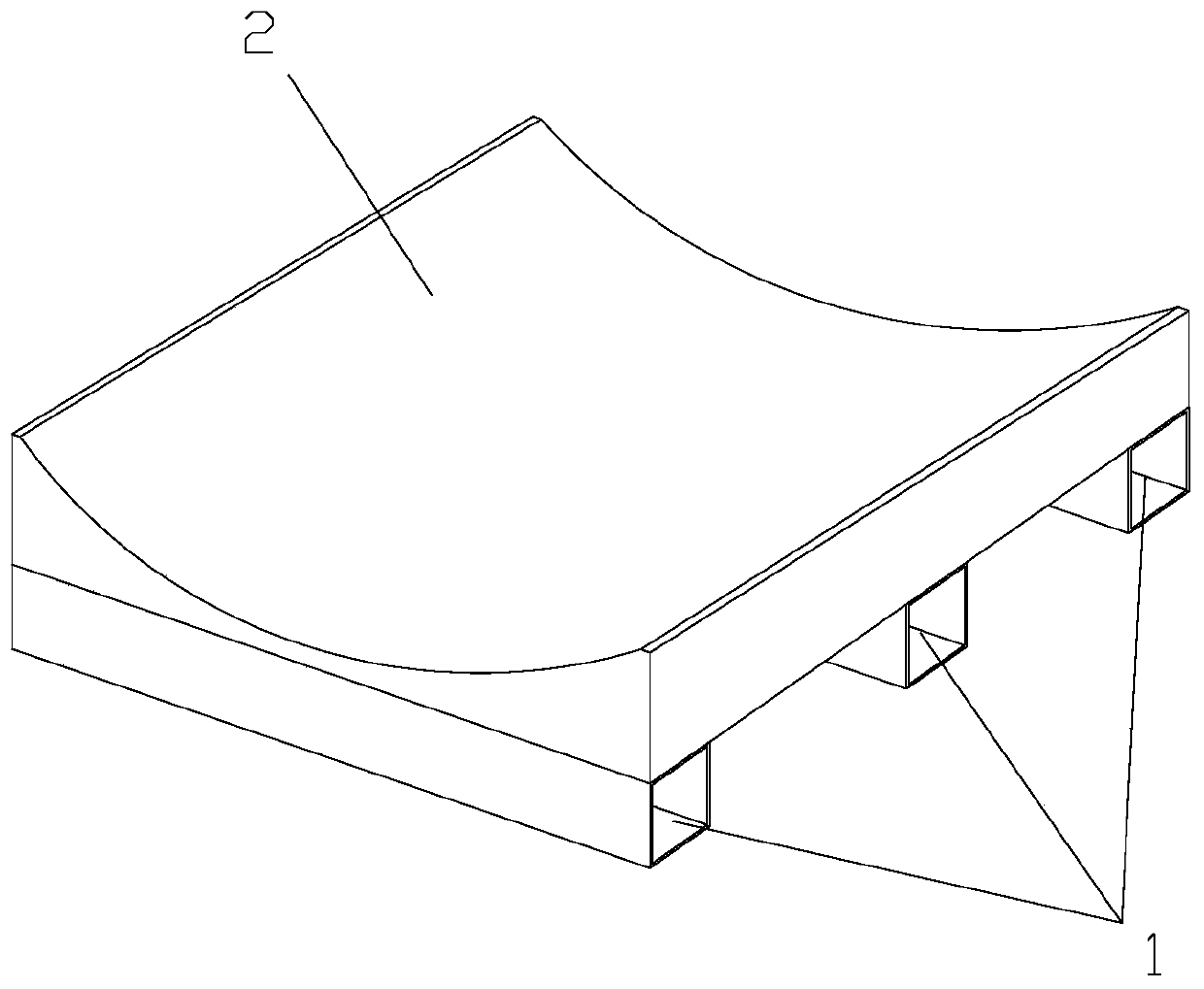

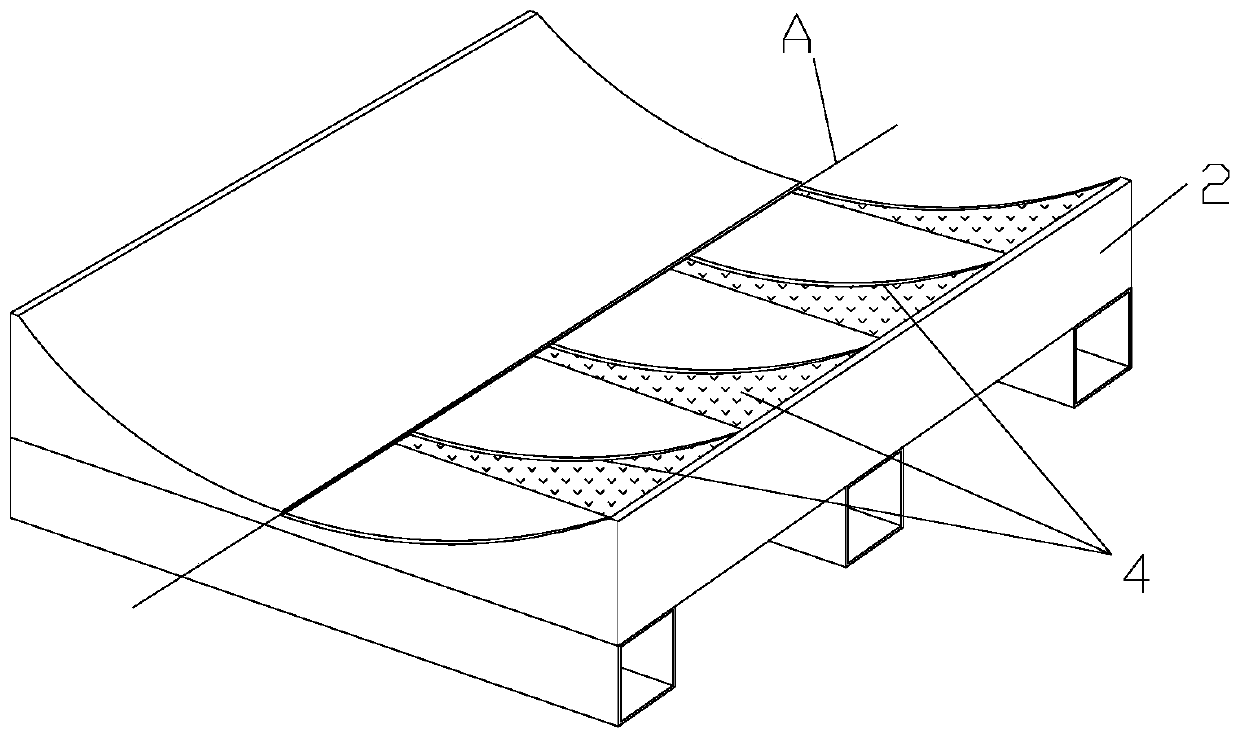

[0032] like figure 1 As shown, this embodiment provides a buffer tray for solvent-free paper-plastic composite or cigarette bale transfer process, including a transport layer 1 , a load-bearing layer 2 , and a buffer layer 3 . The transport layer 1, load-bearing layer 2, and buffer layer 3 are connected sequentially from bottom to top.

[0033] like figure 2As shown, the transportation layer 1 is a plurality of transportation feet, and the transportation feet are fixedly connected with the load-bearing layer. The transport feet can be made of metal compounds or iron-carbon compounds, preferably stainless steel. The transport leg can be designed as a square tube. The square tube has a simple structure, which can greatly reduce the difficulty of processing. A simple structure can meet the demand and can be mass-produced. Certainly, the contact surface between the square tube and the ground, and the contact surface with the load-bearing layer 2 can be made through finishing, ...

Embodiment 2

[0038] like Figure 5 As shown, the present embodiment utilizes the operation method of the buffer tray, comprising the following steps:

[0039] S1: Place the rolled solvent-free paper-plastic composite semi-finished product on the buffer tray. In this step, the solvent-free paper-plastic composite semi-finished product is rewound by using the rewinding seat of the equipment. Since most of the solvent-free paper-plastic composite semi-finished products have a diameter of 1600mm and a weight of 1t, the rewinding seat of the equipment is rewound by means of an inflatable shaft.

[0040] S2: Insert the consignment equipment into the transport layer of the buffer pallet. In this step, the equipment winds up the hydraulic arm to place the solvent-free paper-plastic composite semi-finished product with the air expansion shaft on the buffer tray.

[0041] S3: Place the buffer tray with solvent-free paper-plastic composite semi-finished products in the curing area through the cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com