Vertical glass laser film removing machine

A glass laser and vertical technology, applied in the field of mechanical equipment, can solve the problems of large consumption of consumables, low yield, increased labor costs, etc., and achieve the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

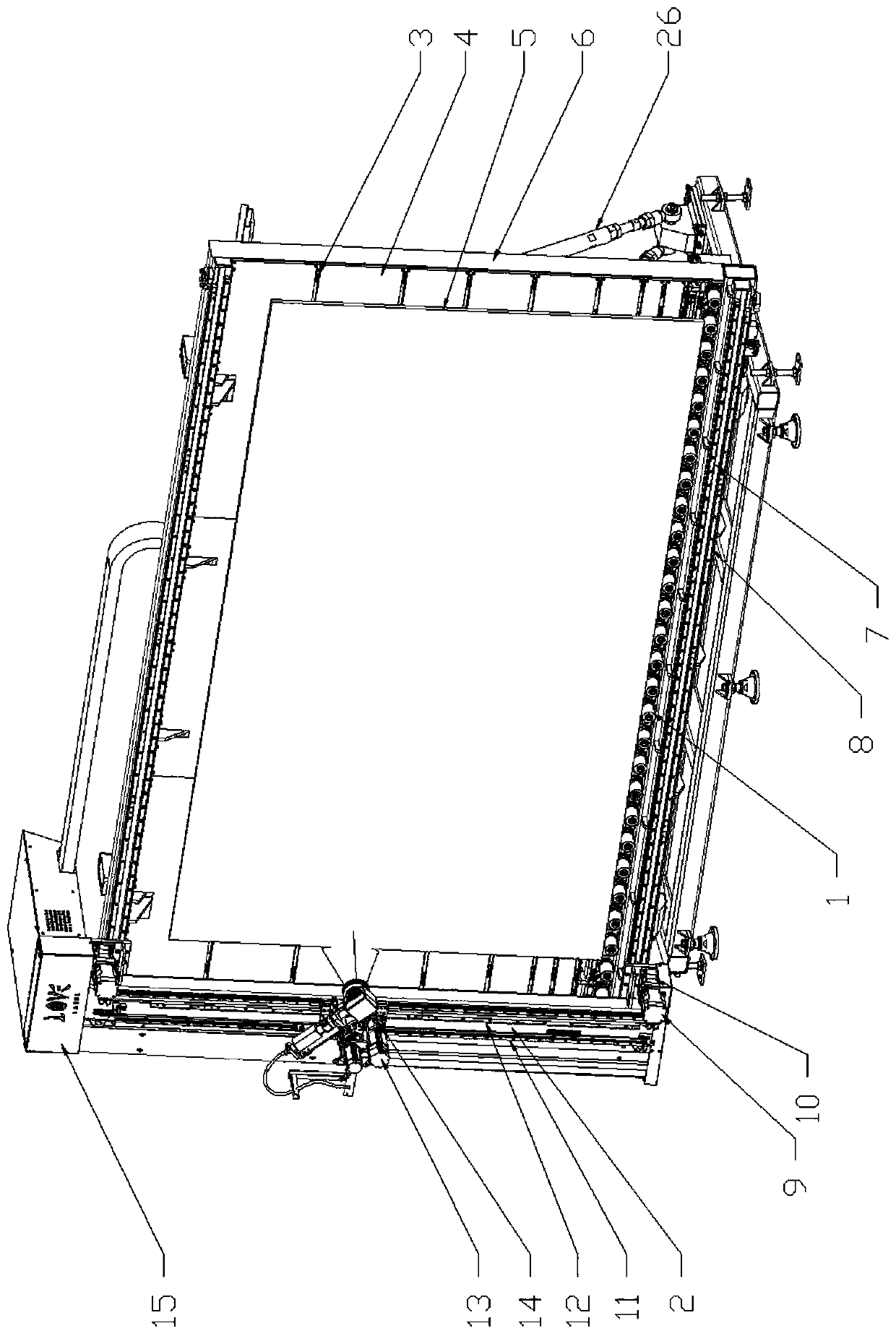

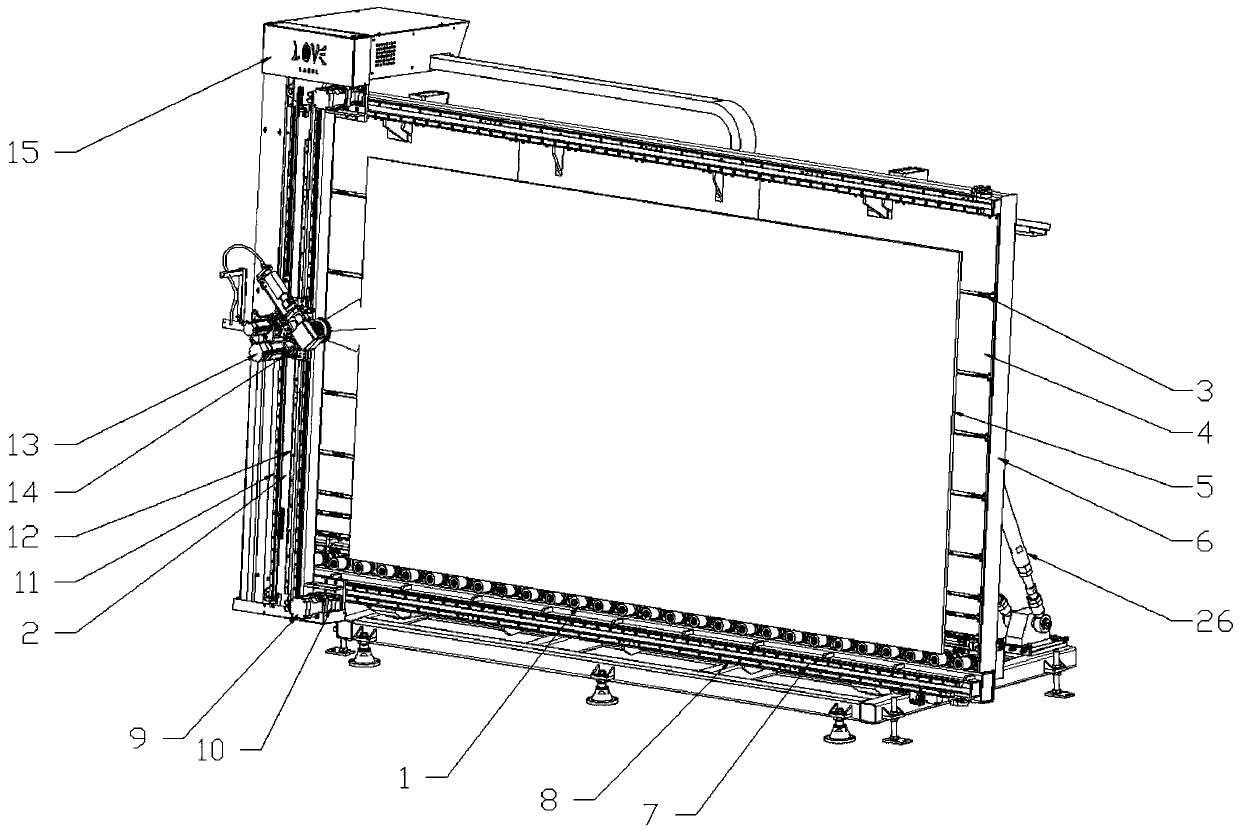

[0029] This embodiment adopts the vertical working format structure, such as figure 1 As shown, it includes a support frame 6, a glass conveying roller 1, a numerically controlled mobile beam 2, a support plate 4 with a supporting small roller 3 on it, and is used to support the glass 5. Of course, other support structures can also be used, such as support rod.

[0030] The support frame 6 is provided with guide rails 7 on the upper and lower sides along the X-axis direction, and racks 8 are arranged parallel to the guide rails 7 . The CNC mobile beam 2 is equipped with two servo motors 9, and a reducer 10 is installed under the servo motor 9. The bottom of the reducer 10 is equipped with a gear, which meshes with the rack 8, and is used to drive the beam 2 to advance in the X-axis direction step back.

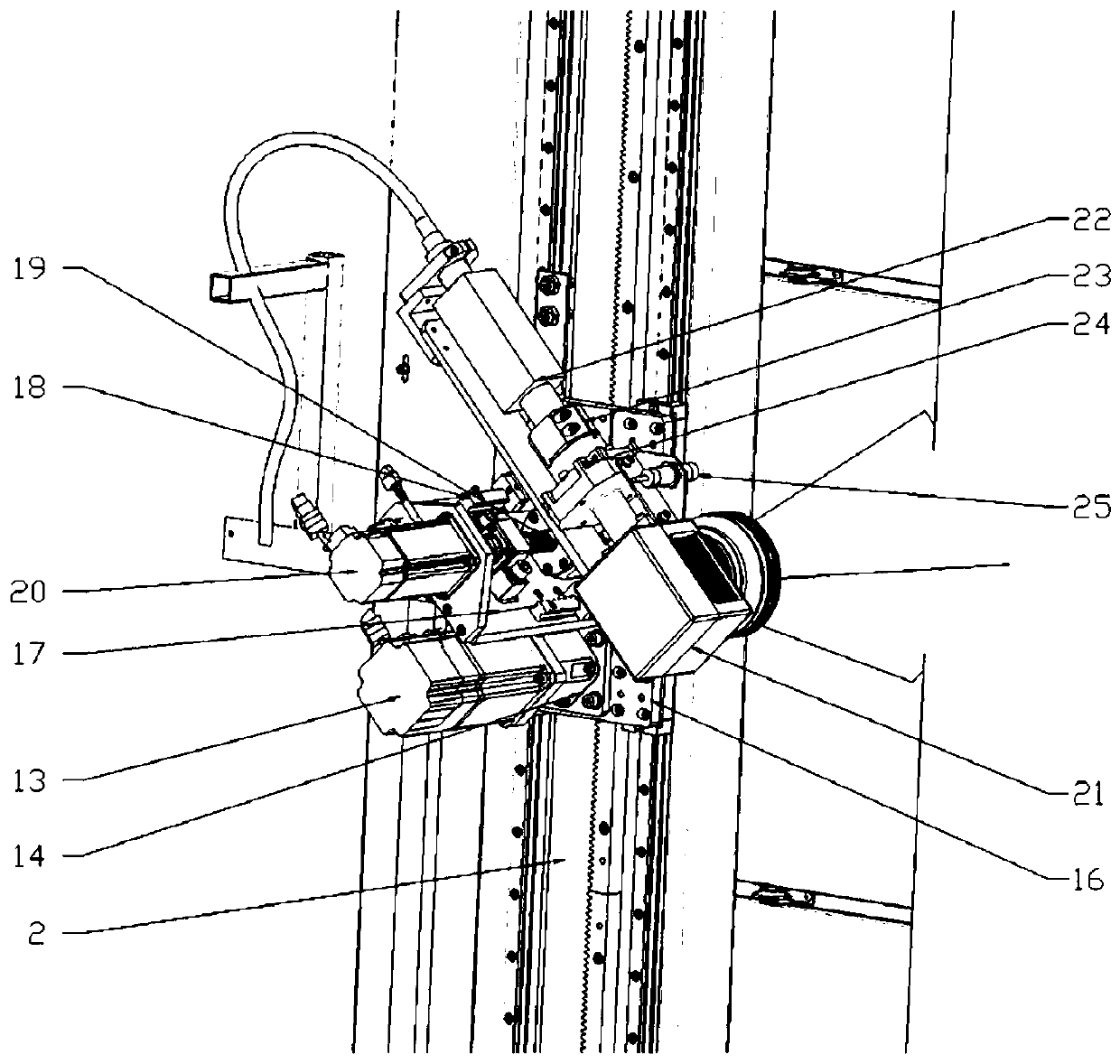

[0031] A guide rail 11 in the Y-axis direction is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com