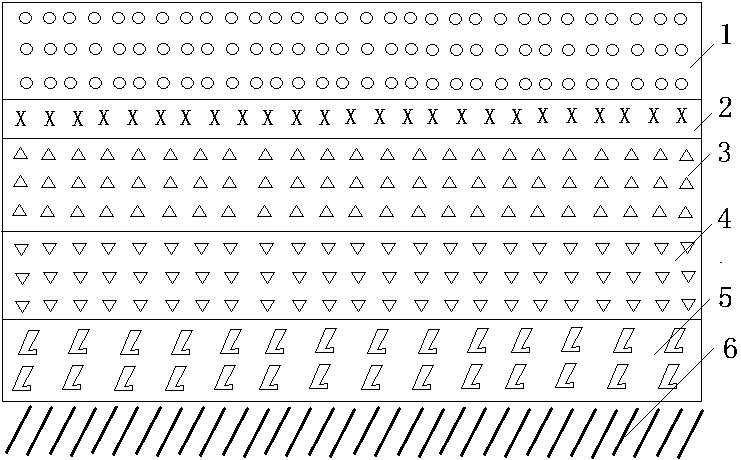

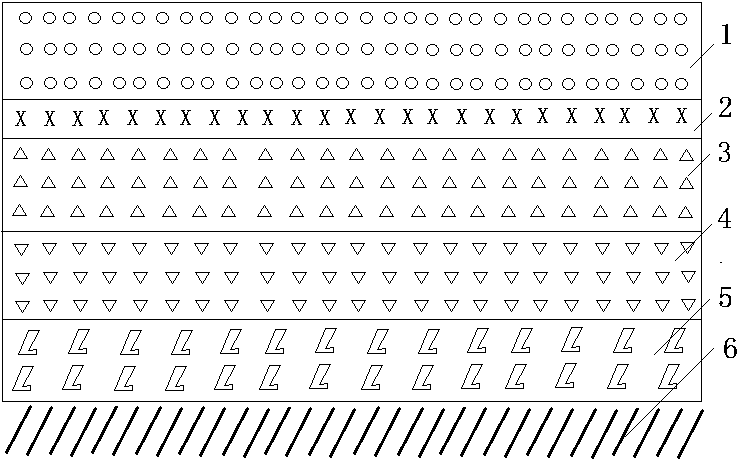

Novel road base structure

A technology for road base and base, which is applied in the direction of roads, roads, and on-site coagulation pavement, etc., can solve the problems of surface cracking, increased bending moment of asphalt surface, increased tensile stress and tensile strain, etc. The effect of reducing the occurrence of cracks, reducing tensile stress and strain, and reducing susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0009] Example 1: The strength of the designed composite base is 6.0MPa. The upper base 3 is waste rubber modified cement stabilized gravel with a thickness of 20cm. The lower base 4 is cement stabilized gravel. The thickness of the upper base 3 is 20cm. , the mineral mix ratio is: 10-30mm crushed stone, 10-20mm crushed stone, 5-10mm crushed stone, stone salt, and waste rubber powder are composed of 25%, 27%, 25%, 17%, and 6%; Waste rubber powder is 40 mesh, and waste rubber powder replaces part of the petite; cement is added at a dose of 8% of the total weight of the mineral material, and the cement type and strength grade are ordinary portland cement of 42.5; the lower base 4 is by weight percentage, ore The material mix ratio is: 10-30mm crushed stone, 10-20mm crushed stone, 5-10mm crushed stone, and stone salt are composed of 25%, 27%, 25%, and 23%; Dosage of cement, cement type and ordinary Portland cement of strength grade 42.5, the thickness of the subbase is 15-25cm. ...

example 2

[0010] Example 2: Design a kind of composite base strength to be 7.0MPa, wherein upper base 3 is waste rubber modified cement stabilized gravel, thickness is 20cm, lower base 4 is cement stabilized gravel, thickness is 20cm, upper base is by weight percentage : 10-30mm crushed stone, 10-20mm crushed stone, 5-10mm crushed stone, stone salt, and waste rubber powder are composed of 25%, 27%, 25%, 19%, and 4%; the particle size of waste rubber powder is 40 mesh, waste rubber powder replaces part of the salt; add cement at a dose of 9% of the total weight of the mineral material, and the cement type and strength grade are ordinary Portland cement of 42.5; the lower base 4 is by weight percentage, and the mineral material mix ratio is : 10-30mm crushed stones, 10-20mm crushed stones, 5-10mm crushed stones, and stone salt are composed of 25%, 27%, 25%, and 23%; the cement dosage is 5.5%, and the cement type and strength grade are 42.5 of ordinary Portland cement.

example 3

[0011] Example 3: The strength of a composite base is designed to be 8.0MPa, wherein the upper base 3 is waste rubber modified cement stabilized gravel with a thickness of 20cm, the lower base 4 is cement stabilized gravel with a thickness of 20cm, and the upper base 3 is by weight percentage It is: 10-30mm crushed stone, 10-20mm crushed stone, 5-10mm crushed stone, stone salt, and waste rubber powder. The composition ratios are 25%, 27%, 25%, 21%, and 2%; Add cement at 10% of the dose, the cement type and ordinary Portland cement with a strength grade of 42.5; the lower base 4 is based on weight percentage, and the mineral mix ratio is: 10-30mm crushed stone, 10-20mm crushed stone, 5-10mm The proportions of gravel and salt are 25%, 27%, 25%, and 23%; cement is added at a dose of 6% of the total weight of the mineral material, and the cement type and strength grade are ordinary Portland cement of 42.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com