Energy-saving vetiver grass oil extraction system

An energy-saving system and vetiver oil technology, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of high energy consumption and low extraction rate of essential oil, so as to reduce process energy consumption, increase extraction rate, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

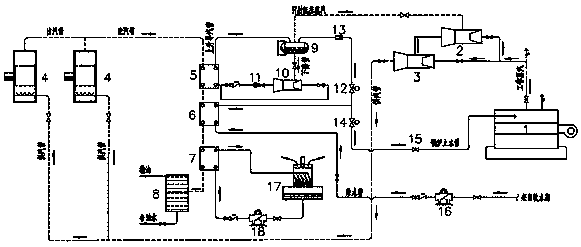

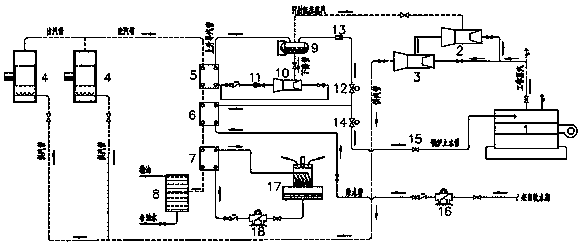

[0026] like figure 1 As shown, the vetiver oil extraction energy-saving system includes a distillation part, a condensation and waste heat recovery part, the distillation part includes a steam boiler 1, a jet compressor and a rotary drum still 4, and the condensation and waste heat recovery part includes a plate evaporator 5 , plate preheater 6, plate cooler 7, oil-water separator 8, low-pressure steam drum 9, forced circulation pump 11, flow regulating valve, pressure reducing valve 13, stop valve 15, feed water pump 16, cooling tower 17 and circulating water pump 18;

[0027] The working steam outlet of the steam boiler 1 is respectively connected to the working steam inlet of the jet compressor I2 and the jet compressor II3 through the flow regulating valve, the steam outlet of the jet compressor I2 is connected to the injection fluid inlet of the jet compressor II3, and the jet compressor Ⅱ3 The steam outlet is connected to the drum still 4, and the cut vetiver rhizome is...

Embodiment 2

[0032] like figure 1As shown, the vetiver oil extraction energy-saving system includes a distillation part, a condensation and waste heat recovery part, the distillation part includes a steam boiler 1, a jet compressor and a rotary drum still 4, and the condensation and waste heat recovery part includes a plate evaporator 5 , plate preheater 6, plate cooler 7, oil-water separator 8, low-pressure steam drum 9, forced circulation pump 11, flow regulating valve, pressure reducing valve 13, stop valve 15, feed water pump 16, cooling tower 17 and circulating water pump 18;

[0033] The working steam outlet of the steam boiler 1 is respectively connected to the working steam inlet of the jet compressor I2 and the jet compressor II3 through the flow regulating valve, the steam outlet of the jet compressor I2 is connected to the injection fluid inlet of the jet compressor II3, and the jet compressor Ⅱ3 The steam outlet is connected to the drum still 4, and the cut vetiver rhizome is ...

Embodiment 3

[0038] like figure 1 As shown, the vetiver oil extraction energy-saving system includes a distillation part, a condensation and waste heat recovery part, the distillation part includes a steam boiler 1, a jet compressor and a rotary drum still 4, and the condensation and waste heat recovery part includes a plate evaporator 5 , plate preheater 6, plate cooler 7, oil-water separator 8, low-pressure steam drum 9, forced circulation pump 11, flow regulating valve, pressure reducing valve 13, stop valve 15, feed water pump 16, cooling tower 17 and circulating water pump 18;

[0039] The working steam outlet of the steam boiler 1 is respectively connected to the working steam inlet of the jet compressor I2 and the jet compressor II3 through the flow regulating valve, the steam outlet of the jet compressor I2 is connected to the injection fluid inlet of the jet compressor II3, and the jet compressor Ⅱ3 The steam outlet is connected to the drum still 4, and the cut vetiver rhizome is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com