Container, preparation method thereof and cooking equipment

A technology of cooking equipment and containers, which is applied in the direction of special materials for cooking utensils, cooking utensils, coatings, etc., and can solve the problems of complex process, difficulty in forming non-stick coating, poor bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

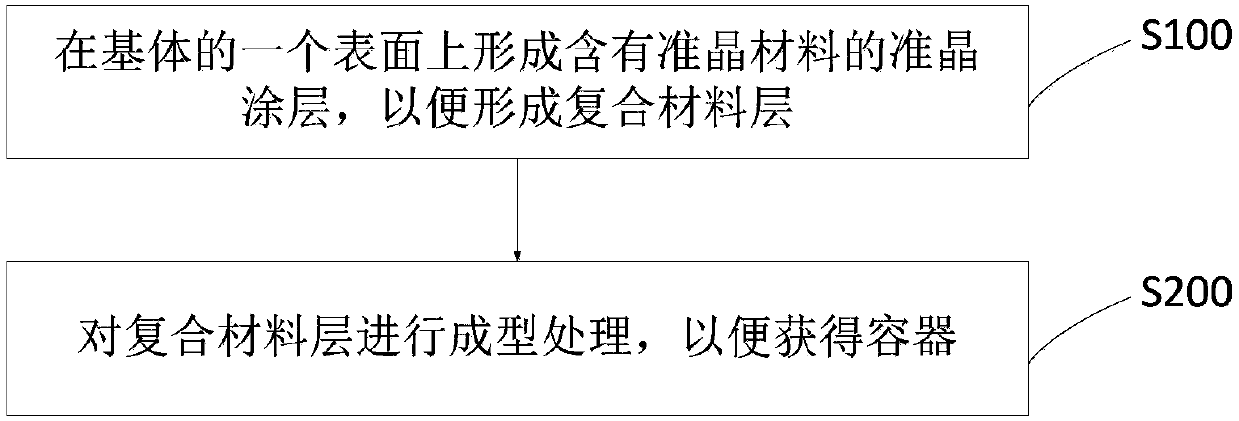

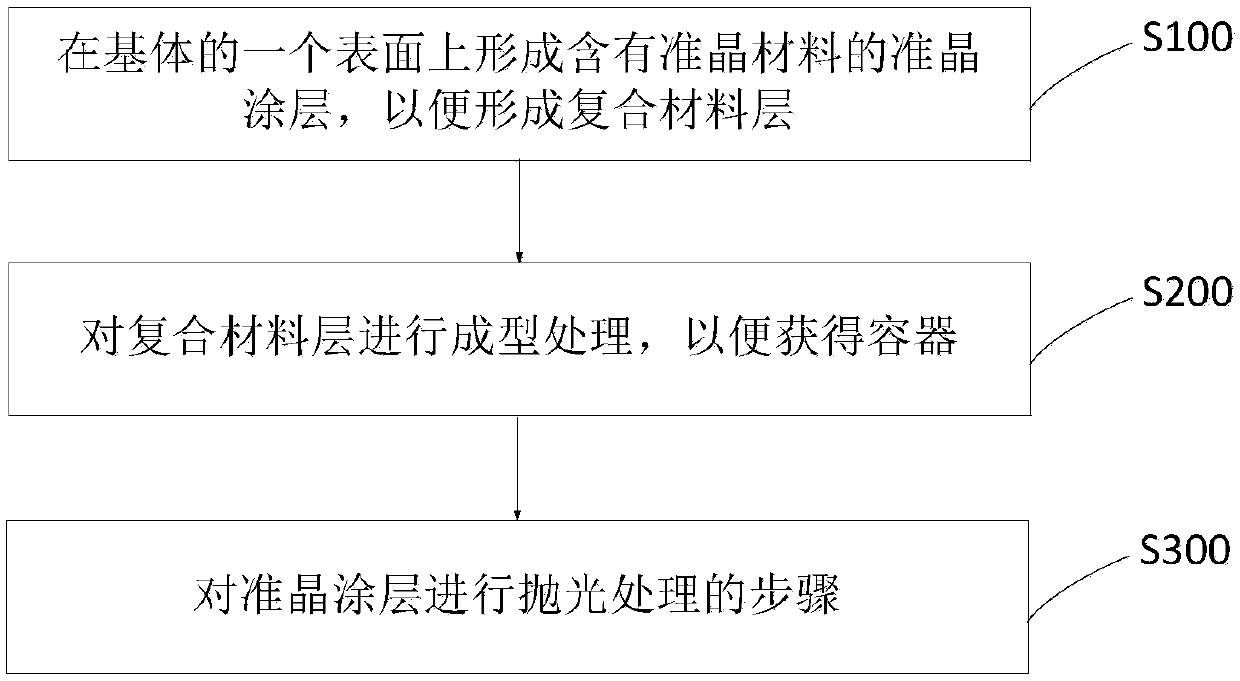

Method used

Image

Examples

Embodiment 1

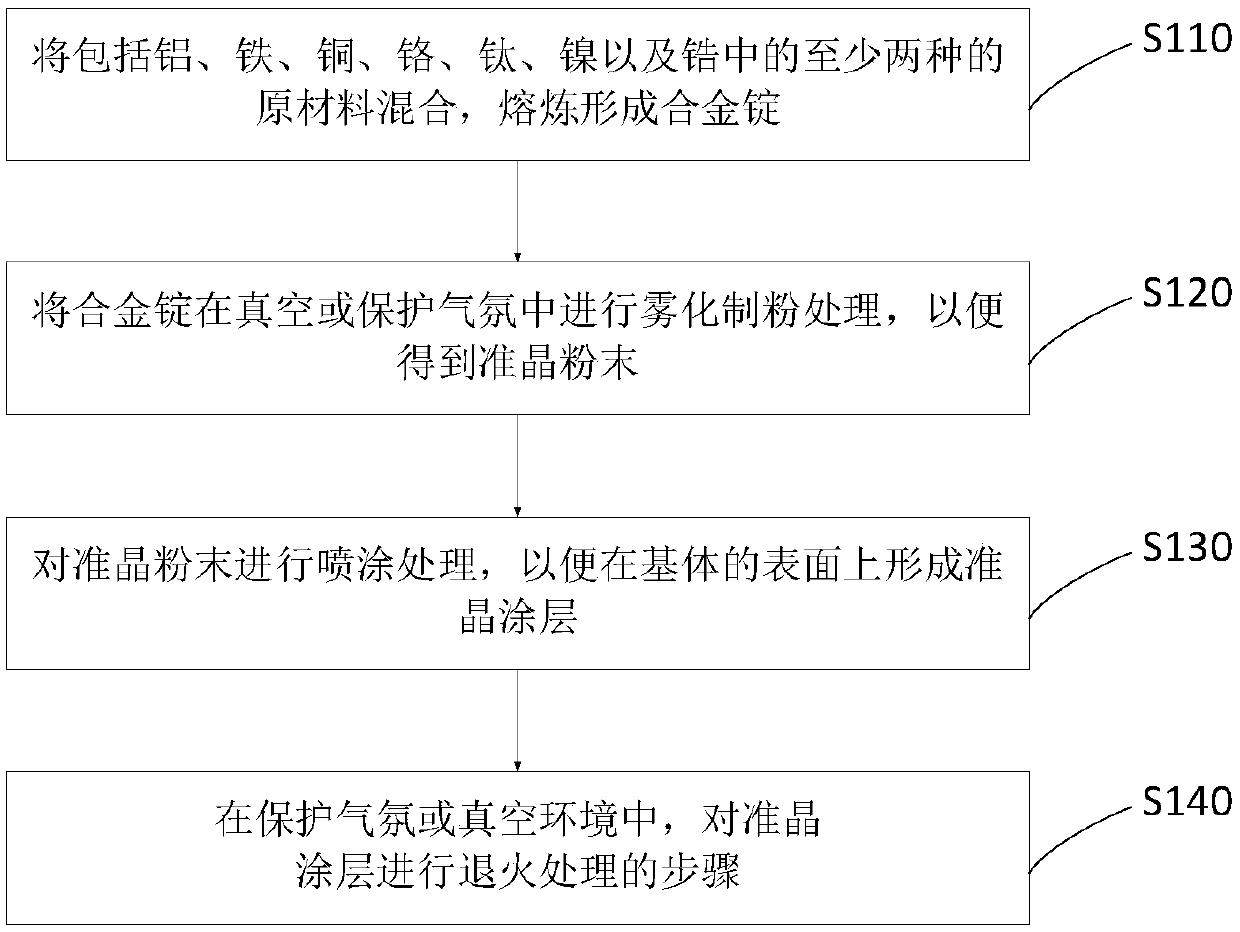

[0086] The steps for preparing the inner bladder include:

[0087] 1. According to the atomic number ratio of Al:Cu:Fe:Cr=60:15:5:5, the alloy raw material is melted into an alloy ingot;

[0088] 2. Atomization powder: In a vacuum or protective atmosphere environment, a powder-milling equipment is used to make quasi-crystalline powder.

[0089] 3. Spheroidization: The quasicrystalline powder is spheroidized and screened to obtain quasicrystalline particles with a particle size of less than 150 microns.

[0090] 4. Substrate surface cleaning: Use alcohol, trichloroethylene or pure water and ultrasonic waves to clean and dry the substrate surface, so that there is no rust on the substrate surface before plasma spraying, and then do sanding treatment to roughen the substrate surface.

[0091] 5. Plasma spraying: use plasma spraying to spray quasicrystalline particles on the surface of the above-mentioned substrate to form a quasicrystalline coating. The spraying power is 30KW, t...

Embodiment 2

[0096] The steps for preparing the inner bladder include:

[0097] 1. According to the atomic number ratio of Al:Cu:Fe:Cr=75:25:15:15, the alloy raw material is melted into an alloy ingot;

[0098] 2. Atomization powder: In a vacuum or protective atmosphere environment, a powder-milling equipment is used to make quasi-crystalline powder.

[0099] 3. Spheroidization: The quasicrystalline powder is spheroidized and screened to obtain quasicrystalline particles with a particle size of less than 150 microns.

[0100] 4. Substrate surface cleaning: Use alcohol, trichloroethylene or pure water and ultrasonic waves to clean and dry the substrate surface, so that there is no rust on the substrate surface before plasma spraying, and then do sanding treatment to roughen the substrate surface.

[0101] 5. Plasma spraying: use plasma spraying to spray quasi-crystalline particles on the surface of the above-mentioned substrate to form a quasi-crystalline coating. min.

[0102] 6. Anneal...

Embodiment 3

[0106] The steps for preparing the inner bladder include:

[0107] 1. According to the atomic number ratio of Al:Cu:Fe:Cr=65:20:10:10, the alloy raw material is melted into an alloy ingot;

[0108] 2. Atomization powder: In a vacuum or protective atmosphere environment, a powder-milling equipment is used to make quasi-crystalline powder.

[0109] 3. Spheroidization: The quasicrystalline powder is spheroidized and screened to obtain quasicrystalline particles with a particle size of less than 150 microns.

[0110]4. Substrate surface cleaning: Use alcohol, trichloroethylene or pure water and ultrasonic waves to clean and dry the substrate surface, so that there is no rust on the substrate surface before plasma spraying, and then do sanding treatment to roughen the substrate surface.

[0111] 5. Plasma spraying: use plasma spraying to spray quasicrystalline particles on the surface of the above-mentioned substrate to form a quasicrystalline coating. The spraying power is 40KW, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com