Construction method of tunnel two-lining concrete pouring liquid level monitor

A construction method and concrete technology, applied in tunnel lining, tunnel, earthwork drilling and mining, etc., can solve problems such as easy cracking of secondary lining, instability and falling of surrounding rock, water leakage, etc., to reduce vault voids, improve construction quality, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

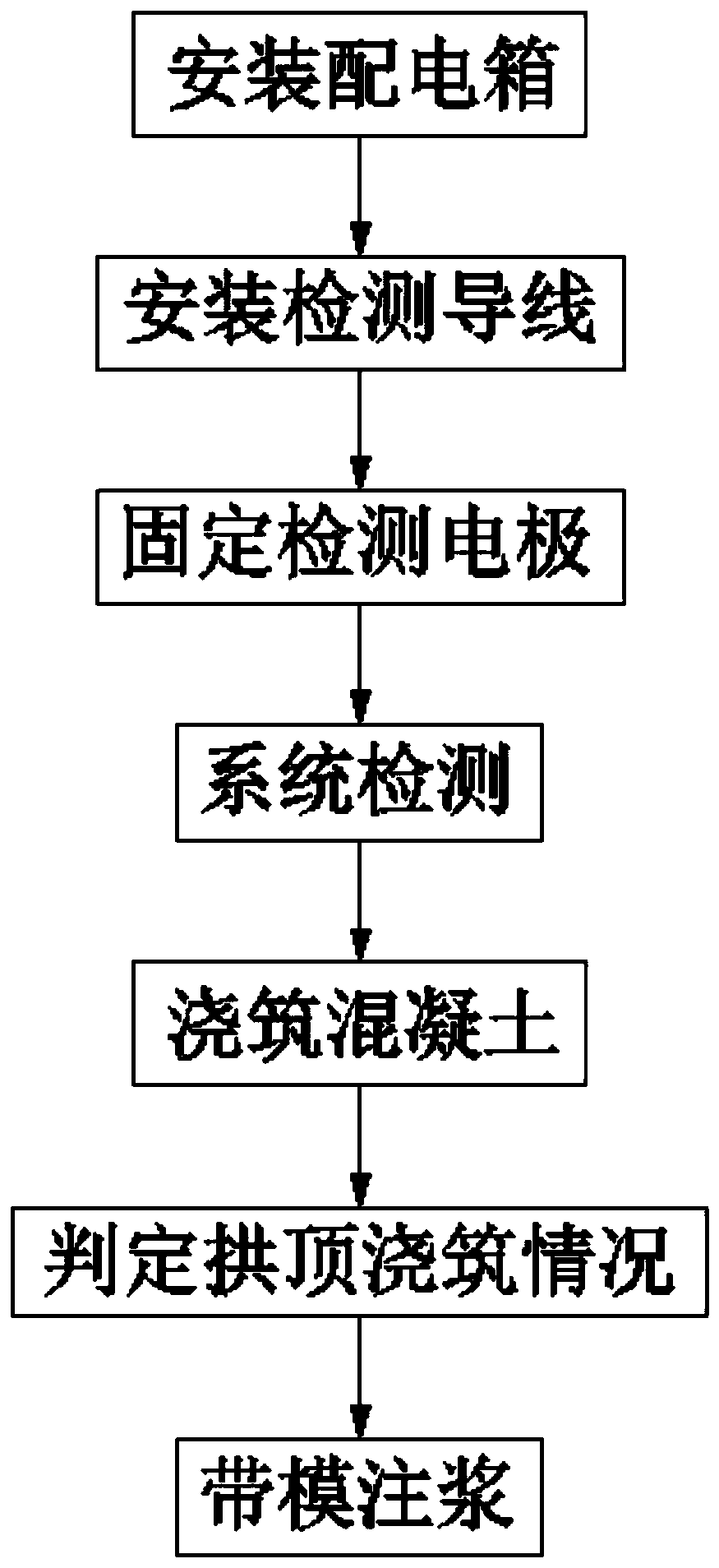

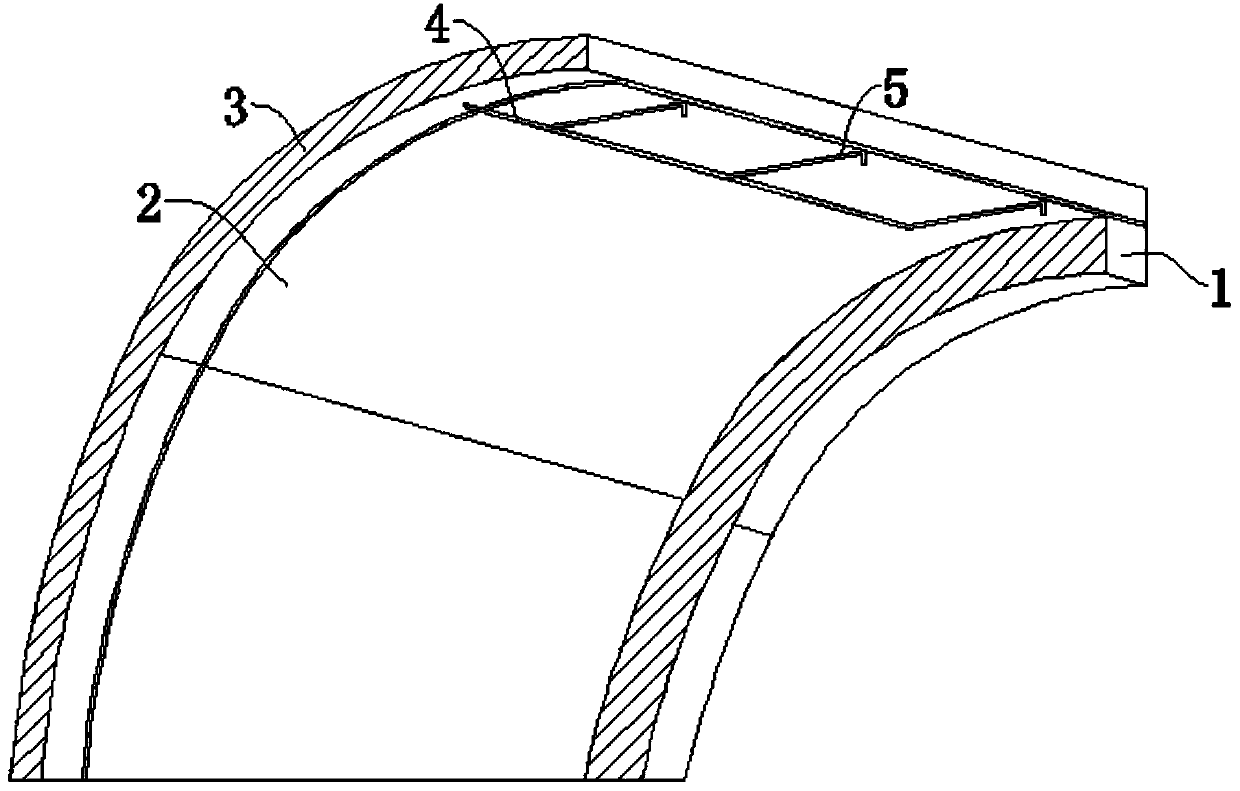

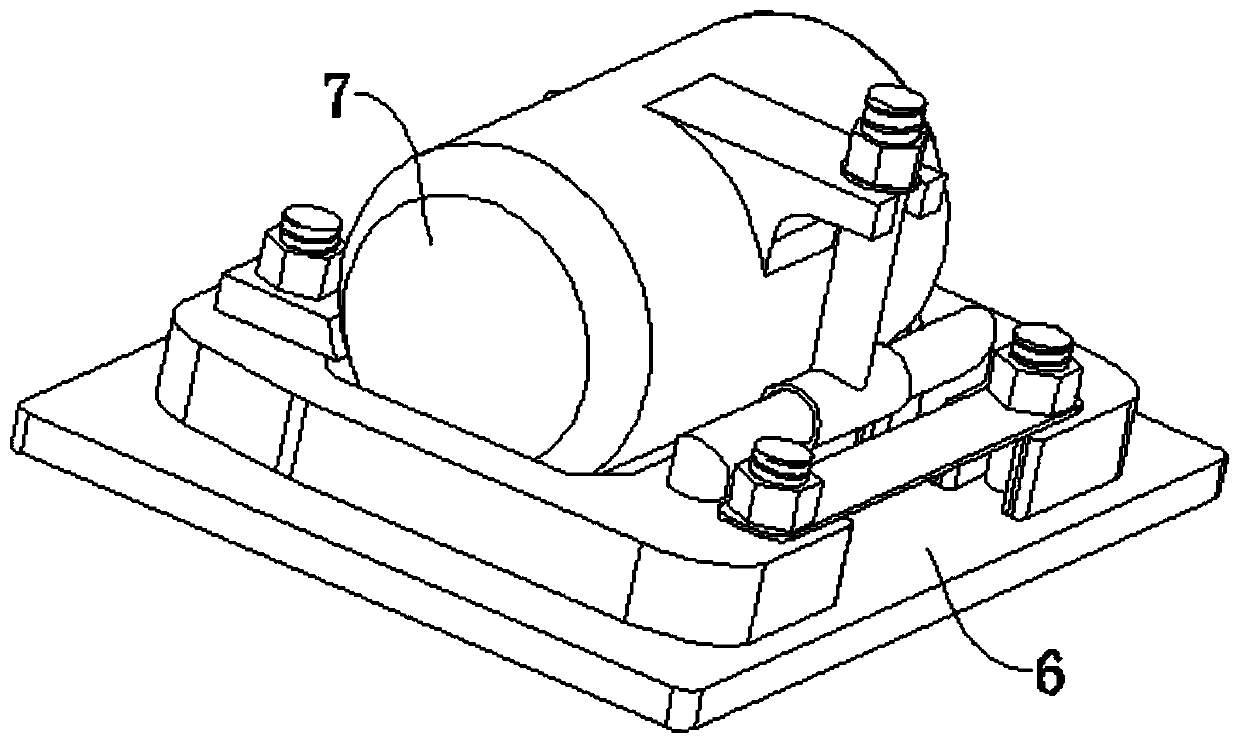

[0033] Embodiment: A construction method for the liquid level monitor of the concrete pouring of the second lining of the tunnel. The liquid level monitor of the concrete pouring of the second lining of the tunnel includes 1 distribution box, 1 two-phase leakage protector, 3 liquid level relays, and 3 intermediate Relay, 3 double-core detection wires 4 and 3 signal lamps. The liquid level relay is composed of a liquid level detection electrode 5 (wire), a signal processing circuit and an output execution relay. When the power is turned on, the signal processing circuit judges the current position of the liquid level according to the level signals provided by the two electrodes, and drives the output execution relay, which turns on or off the signal light to achieve the purpose of controlling the liquid level. . Working sequence: power supply→single-phase leakage protector→liquid level relay JBY-714→detection wire 4→liquid level relay signal processing circuit→intermediate rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com