Sheet-shaped stacked structure getter pump

A getter pump and getter technology, applied in pumps, liquid variable displacement machines, machines/engines, etc., can solve the problems of reduced effective pumping speed, uneven heating, and low heating efficiency, and achieve optimal flow conductance , Fully uniform heating and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

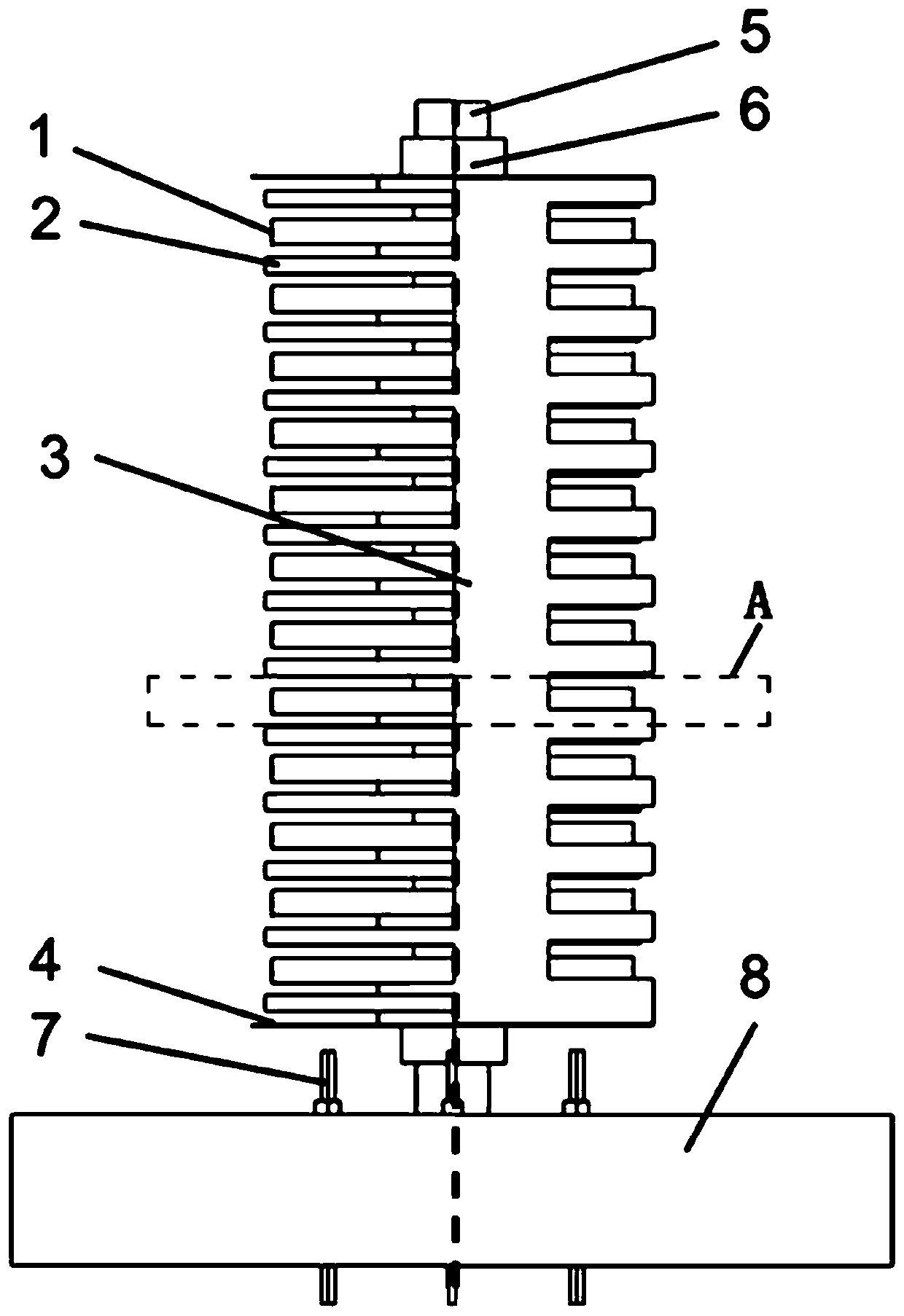

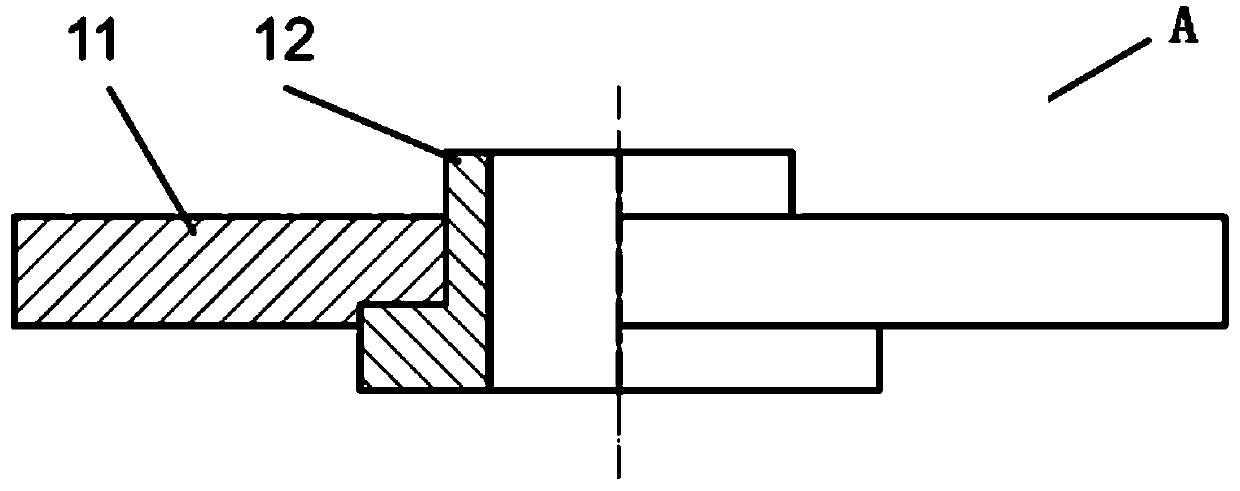

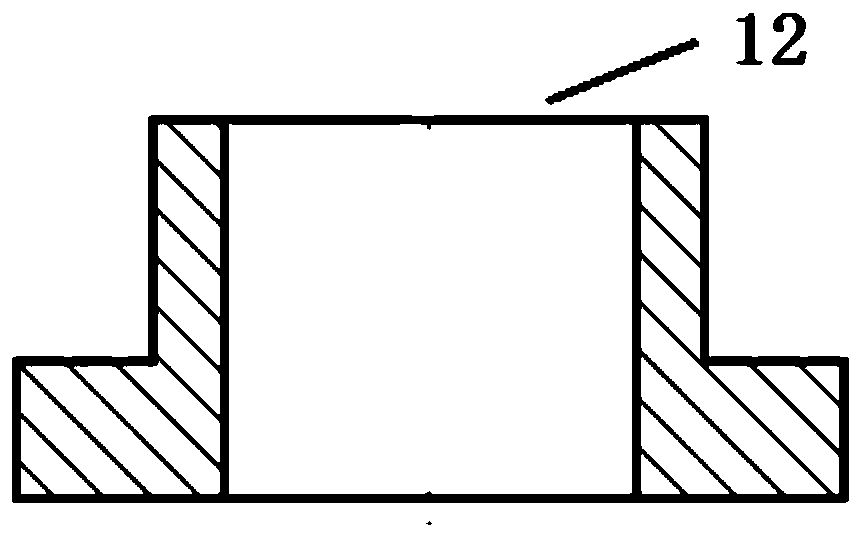

[0033] Before assembling the getter pump, it is necessary to prepare the getter element 1: put the central step gasket 12 (made of 304 stainless steel) into the mold, fill in the getter powder (ZrVFe powder, 300 mesh), and carry out loose packing Sintering molding, the sintering temperature is 920° C.; finally a sheet-shaped getter element is obtained, with a thickness of 2 mm and a diameter of 28 mm.

[0034] Then fix the central support rod 5 with a specific tooling fixture, fix a heat shielding layer 4 on the support rod 5 with a nut 6, stack 9 pieces of suction elements 1 and 10 pieces of ceramic heating chips 2 alternately on the central support rod 5, The middle is separated by the central step gasket 12 of the suction element 1 . Install the hollow shell 3 on the heat shielding layer 4, continue to install another piece of heat shielding layer, and clamp it to the central support rod 5 with the nut 6.

[0035] Finally, the electrode lead wires of each ceramic heating c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com