Mechanical-thermal coupling fatigue testing device for in-situ analysis of infrared spectrometer

An infrared spectrometer and in-situ analysis technology, which is applied in the field of miniature fatigue test devices, can solve the problems of obvious backlash, unnegligible influence, large volume, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

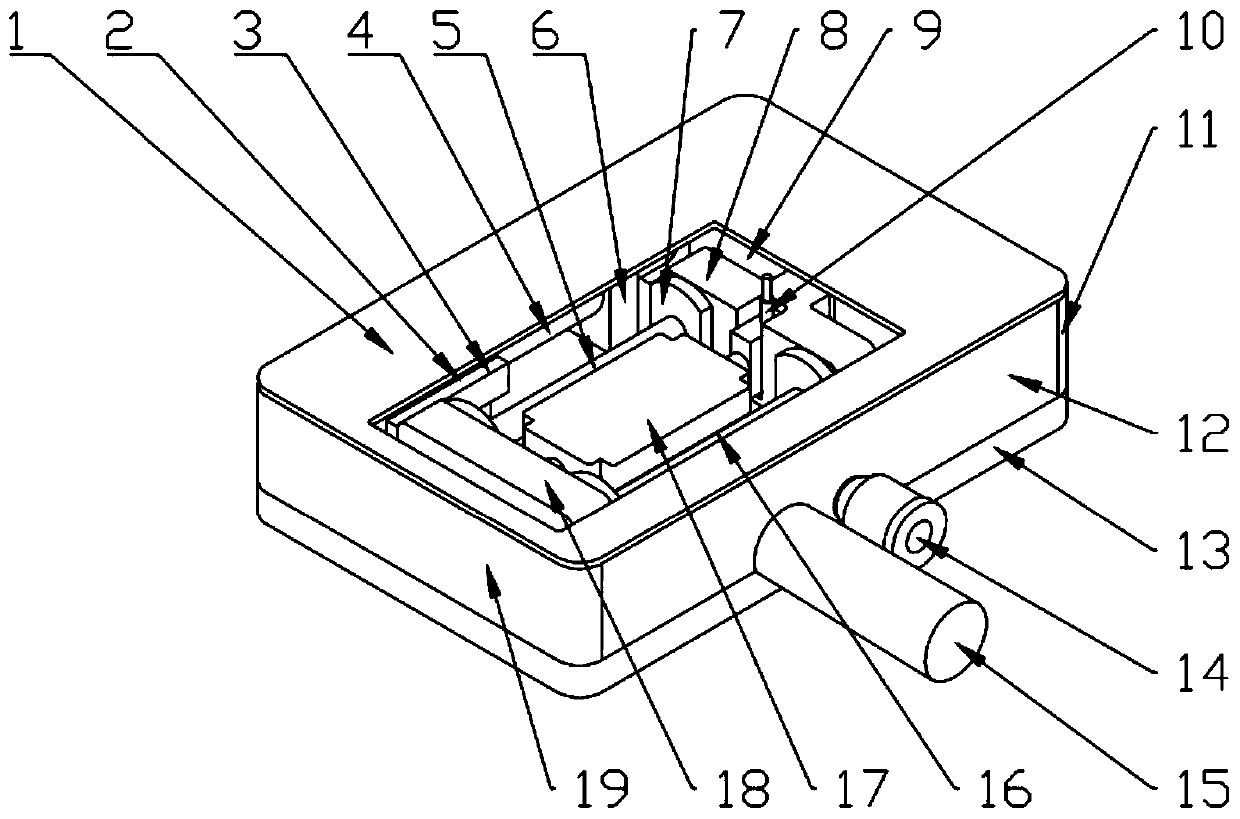

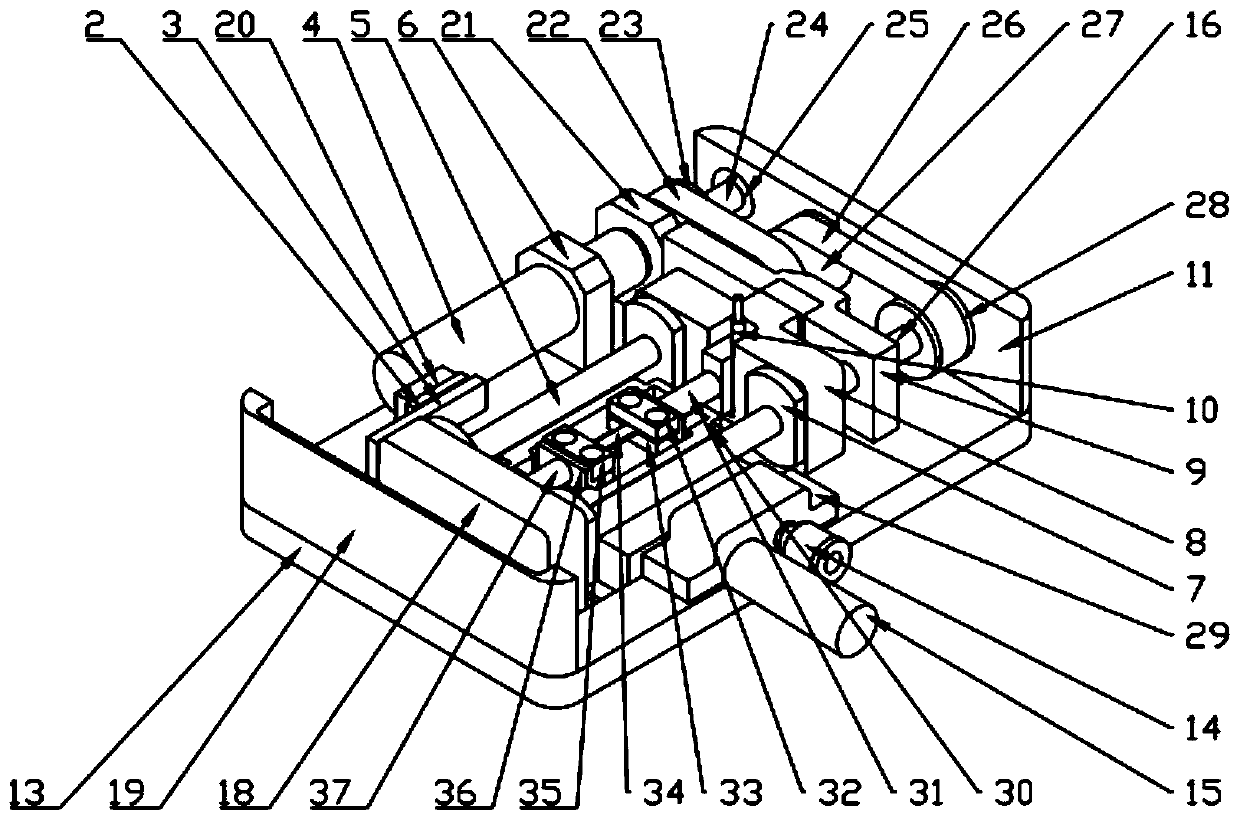

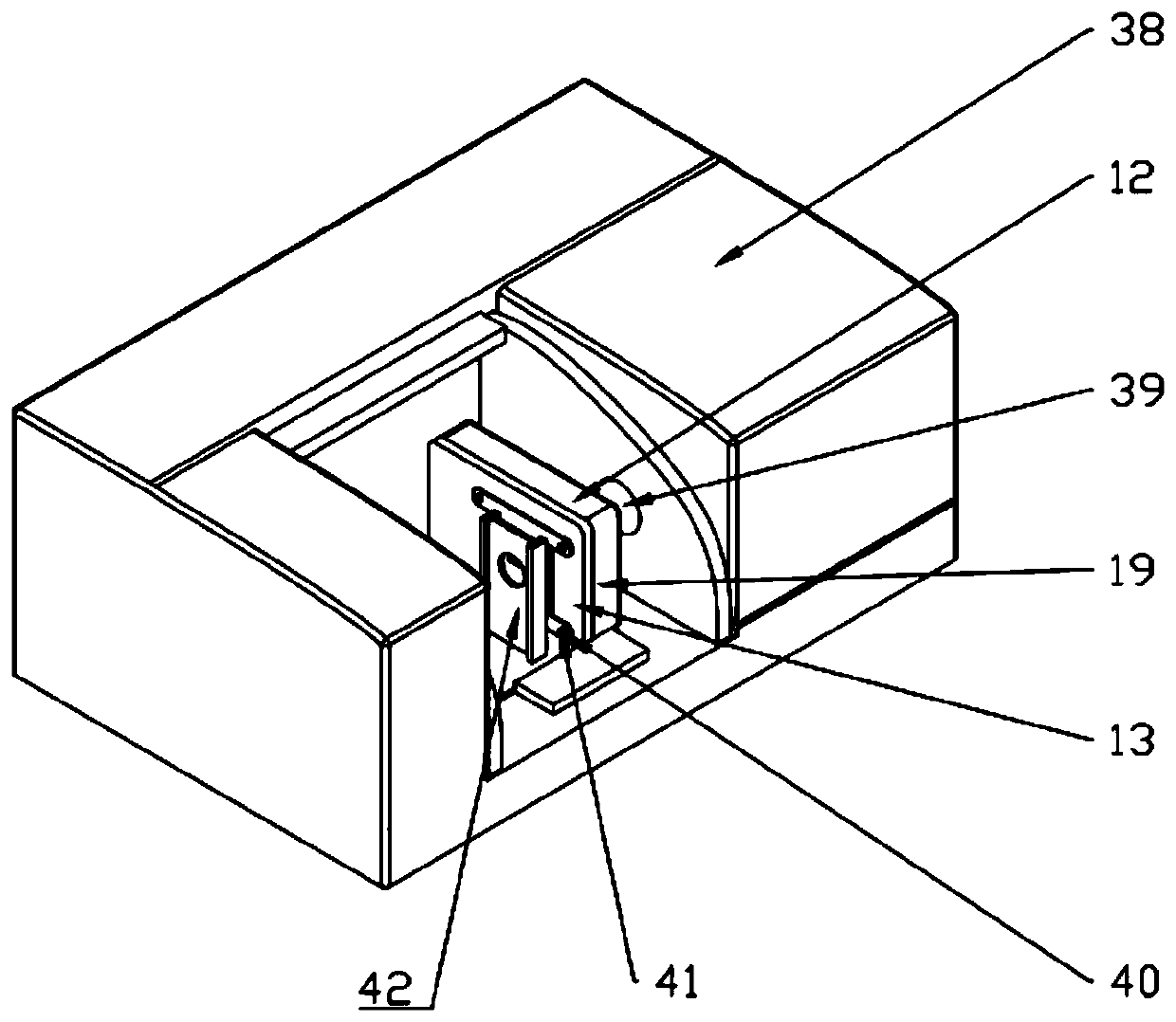

[0028] Such as figure 1 and figure 2 As shown, this embodiment provides a mechanical-thermal coupling fatigue test device for in-situ analysis of an infrared spectrometer, which is mainly composed of a structure, a mechanical loading unit, a data acquisition unit and an environmental loading unit.

[0029] The structural body includes an outer cover plate, a middle support plate 9 , a motor fixing block 6 and a pulley fixing block 21 . The mechanical loading unit and the data acquisition unit are arranged inside the outer cover plate, and the outer cover plate mainly plays a shielding role. The outer cover plate consists of an upper cover plate 1 at the top, a bottom plate 13 at the bottom, side plates 12 at both sides, first support plates 11 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com