Boiler exhaust emission prediction model establishing method, prediction method and device

A prediction model and boiler exhaust gas technology, applied in prediction, neural learning methods, biological neural network models, etc., can solve the problems of high input cost, poor generalization ability, and low prediction accuracy, and achieve strong anti-noise ability and training speed Fast, fast convergence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

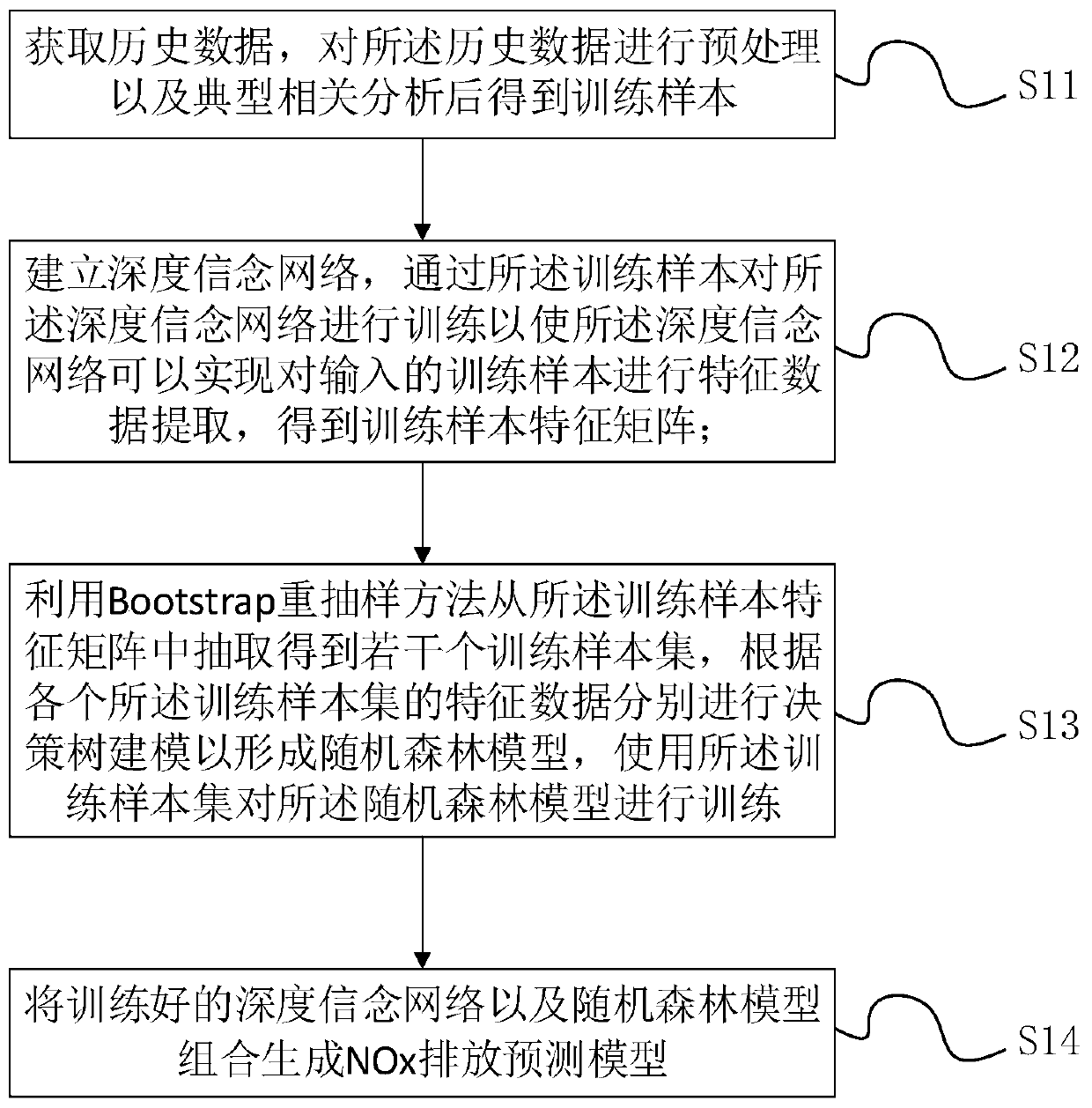

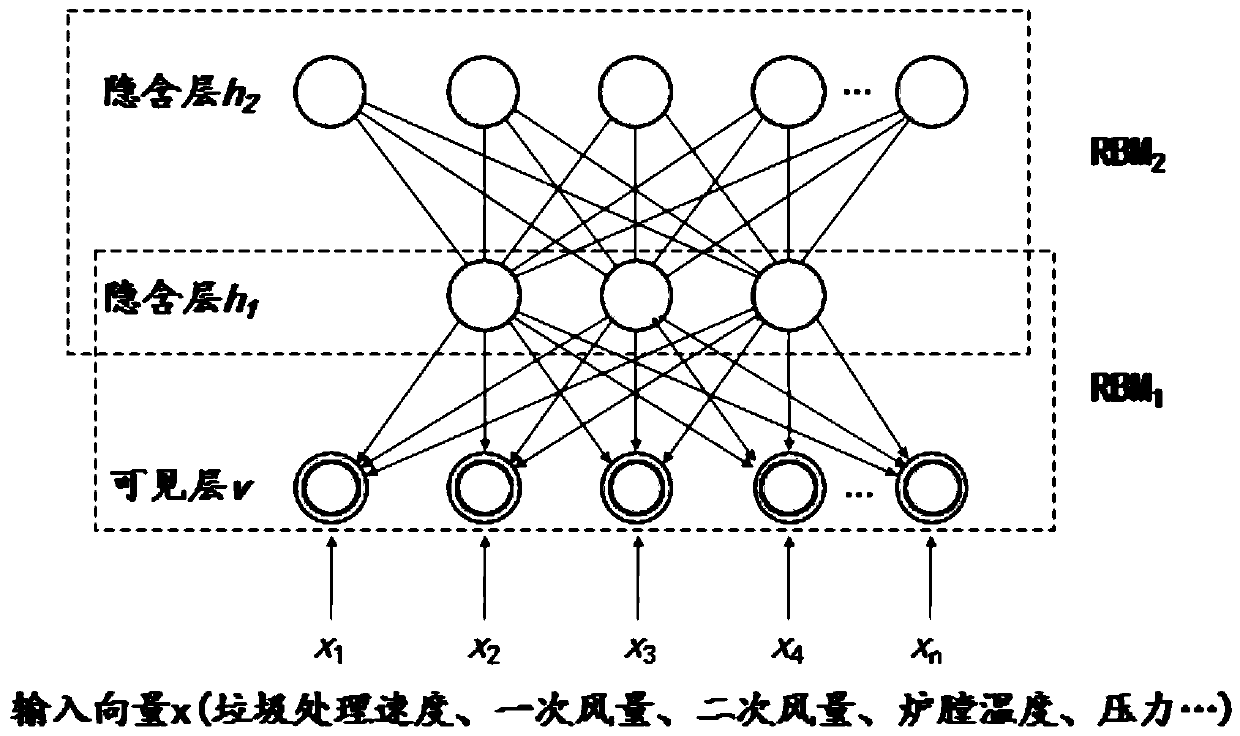

[0047] There are many types of waste gas in the waste incinerator flue gas, such as NOx, CO, SO 2 , NH 3 etc., the boiler exhaust gas emission prediction model establishment method provided by the present invention can respectively establish the emission prediction models corresponding to each exhaust gas type, such as NOx emission prediction model, CO emission prediction model, SO 2 Emission prediction model, NH 3 Emission prediction models, etc., only need to obtain the historical data of the corresponding exhaust gas. For example, when the NOx emission prediction model needs to be established, the input sample matrix x and the NOx output matrix y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com