Steel-tape armoring polyvinyl chloride sheath processing equipment capable of avoiding extrusion

A polyvinyl chloride sheath and steel tape armoring technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems such as shortening the service life of cables, internal cable extrusion, and reducing cable safety and cable quality , to avoid thinning, avoid shaking, improve safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

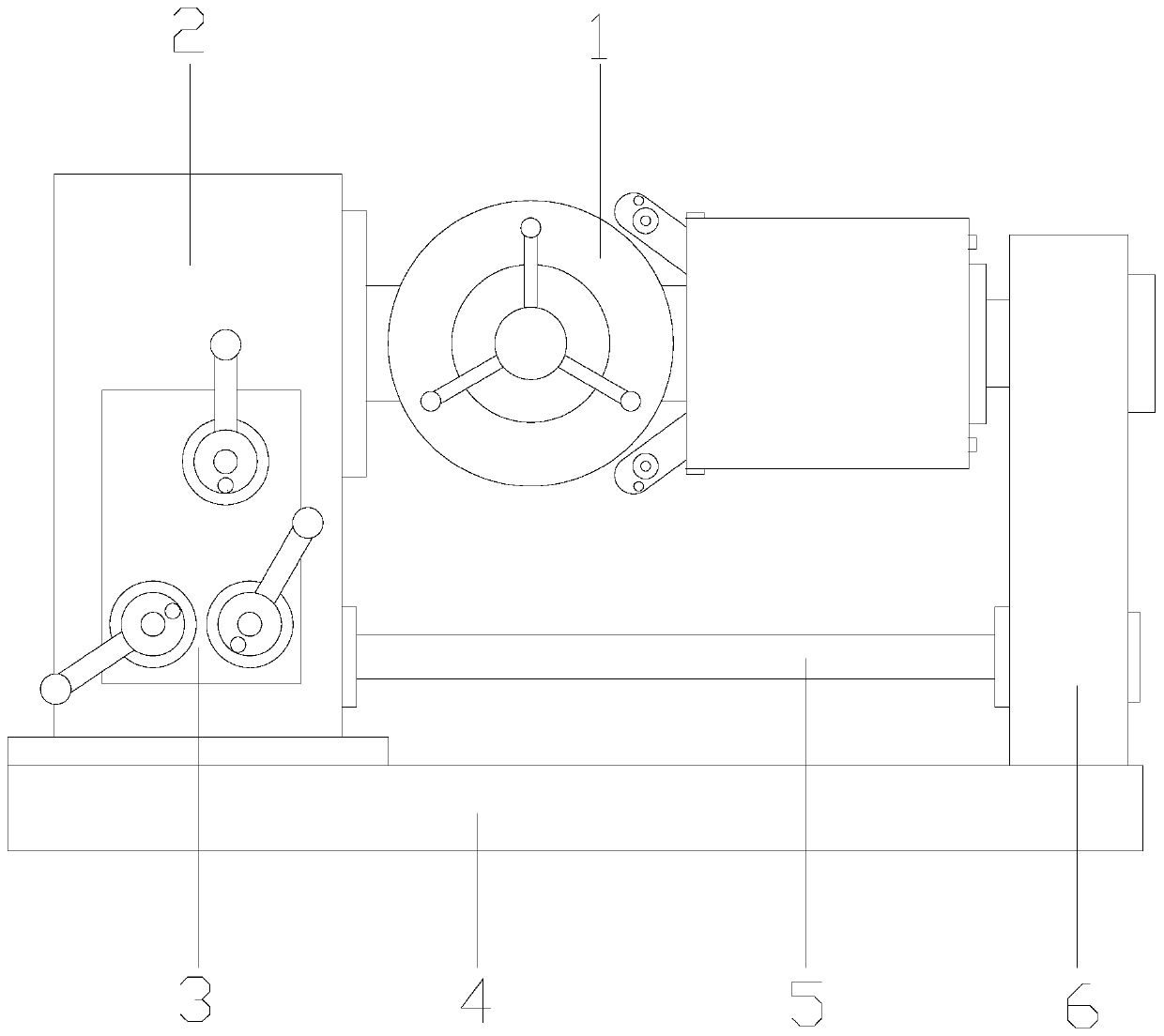

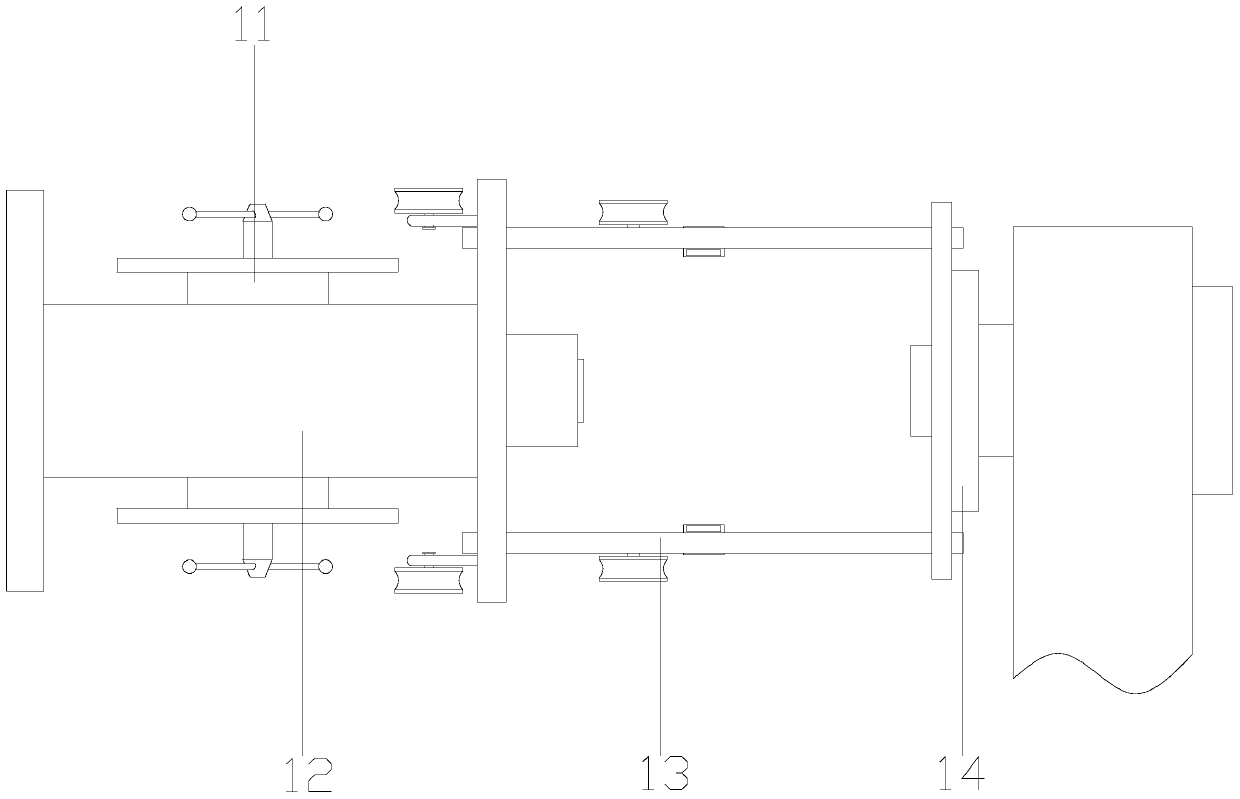

[0028] see Figure 1-Figure 6, the present invention provides a steel tape armored polyvinyl chloride sheath processing equipment that avoids extrusion, and its structure includes an armored processing device 1, a motor drive box 2, a control panel 3, a fixed base 4, a transmission roller shaft 5, The cable conveying frame 6, the fixed base 4 is rectangular and installed horizontally on the ground, the motor drive box 2 is fixed on the left end of the upper surface of the fixed base 4 by bolts, and the control panel 3 is located at the bottom of the front of the motor drive box 2 , the cable conveyor frame 6 is vertically installed on the right end of the upper surface of the fixed base 4, the left and right ends of the drive roller shaft 5 are respectively buckled with the motor drive box 2 and the cable conveyor frame 6, and the armored processing device 1 is installed Between the motor drive box 2 and the cable delivery frame 6, the armoring processing device 1 is composed ...

Embodiment 2

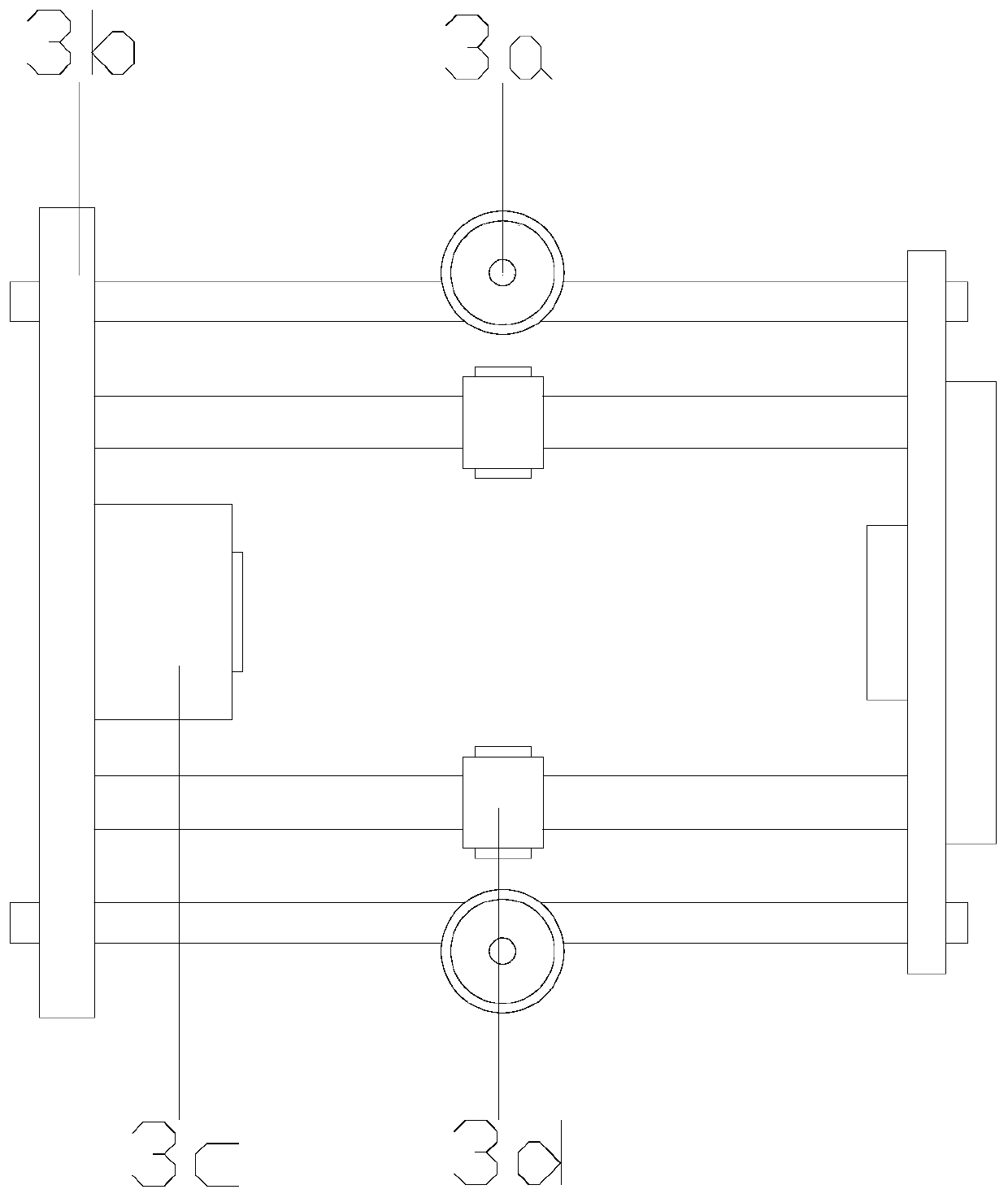

[0031] see Figure 7-Figure 9 , the steel belt self-adjusting device 3d is composed of a steel belt transmission device d1, a fixed sliding rod d2, and a sliding regulator d3, the fixed sliding rod d2 and the regulator fixing frame 3b are interlocked, and the sliding regulator d3 and The fixed slide bar d2 is close together, the steel belt transmission device d1 is located behind the slide adjuster d3, and the fixed slide bar d2 and the slide adjuster d3 are concentric circle structures. The steel belt transmission device d1 is composed of a steel belt transmission shaft wheel d11, a transmission device fixing seat d12, a steel belt output port d13, a self-adjusting drive plate d14, and a steel belt input port d15. The transmission device fixing seat d12 is connected with a sliding adjustment The devices d3 are fastened together, the steel belt input port d15 is nested in the middle of the upper surface of the transmission device fixing seat d12, the steel belt output port d13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com