Method of coating solid electrolyte with electrode material, coating material, and electrode prepared using coating method

A solid electrolyte and electrode material technology, applied in solid electrolytes, non-aqueous electrolytes, battery electrodes, etc., can solve problems such as reducing the battery performance of positive electrode materials, and achieve the effects of improving contact, reducing porosity, and optimizing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The Li surface synthesized by n-hexane as solvent 3 InCl 6 NCM523 cathode material coated particles

[0047] 1g Li 3 InCl 6 Add it to 30ml of anhydrous n-hexane solvent, then put it into a cell crusher to crush it (ultrasonic power 600W, working frequency 20-20KHz) for 10min, and the temperature does not exceed 60°C, then let it stand for 5min to remove the upper liquid, The upper layer liquid was transferred to a beaker with 5g of NCM523 on the bottom layer, then placed in an ultrasonic instrument for 20min, and then transferred to a vacuum drying oven at 85°C for 12 hours to finally obtain the surface Li-containing 3 InCl 6 NCM523 cathode material coated particles.

Embodiment 2

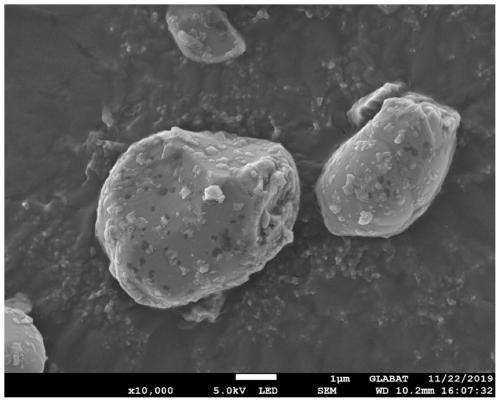

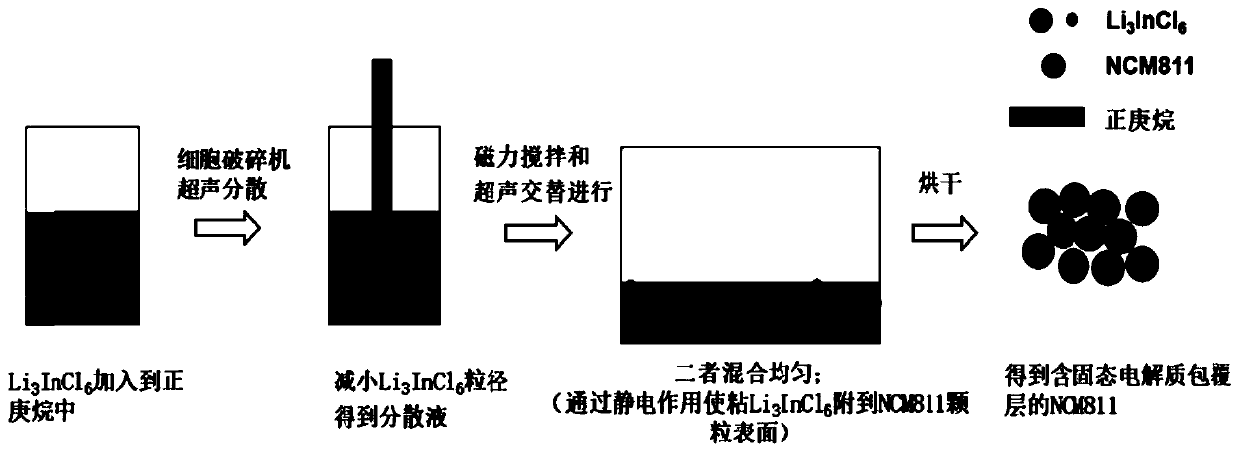

[0048] Embodiment 2 n-heptane is used as the Li-containing compound synthesized by solvent 3 InCl 6 NCM811 cathode material for cladding layer

[0049] 3g Li 3 InCl 6 Add it to 60ml of anhydrous n-heptane solvent, and then put it into a cell crusher for crushing (ultrasonic power 350W, working frequency 20-20KHz) ultrasonic time 2min interval 2min, ultrasonic 10 times, and the temperature does not exceed 60°C. Then weigh 7g of NCM811 and put it into the ultrasonically dispersed liquid, alternately carry out magnetic stirring and ultrasonic cleaning for 30min, and then put it into a vacuum drying oven at 100°C for 12 hours to dry, and finally obtain the Li-containing 3 InCl 6 The NCM811 cathode material of the cladding layer. The obtained sample containing the cladding layer was treated with Li 3 InCl 6 The solid-state electrolyte and In sheet are tested with a blue electric tester by pressing in a mold to form a molded solid-state battery of active material-electrolyte-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com