Switched reluctance motor sensorless control method

A technology of switched reluctance motor and control method, applied in motor generator control, AC motor control, electronic commutation motor control, etc., can solve problems such as reducing system reliability, debugging and initial positioning workload, and increasing system cost. , to achieve the effect of reducing system cost, easy digital implementation, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Taking a three-phase 6 / 4-pole switched reluctance motor as a prototype, the steps of the position sensorless control method for the switched reluctance motor provided by the present invention are as follows:

[0042] 1) Use the current slope difference method to measure the value of the phase incremental inductance of the prototype under different phase currents at the position where the rotor and the stator poles are completely aligned, where the rotor pole edge is aligned with the stator pole center, and where the rotor pole is completely aligned with the stator groove center . The formula for estimating the phase increment inductance by the current slope difference method is:

[0043]

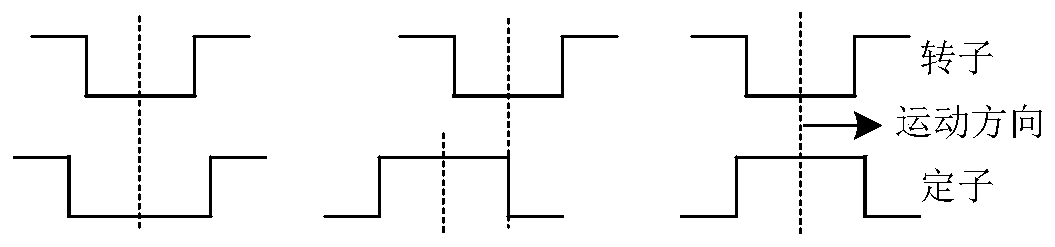

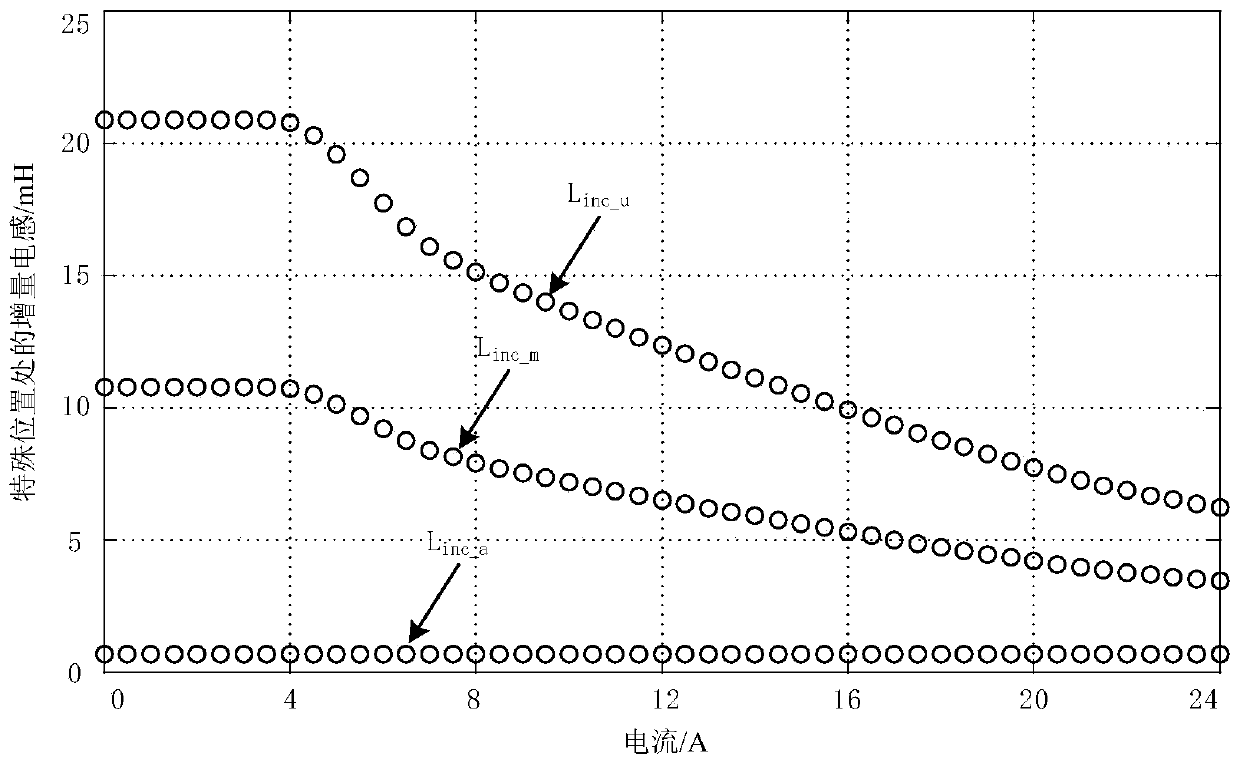

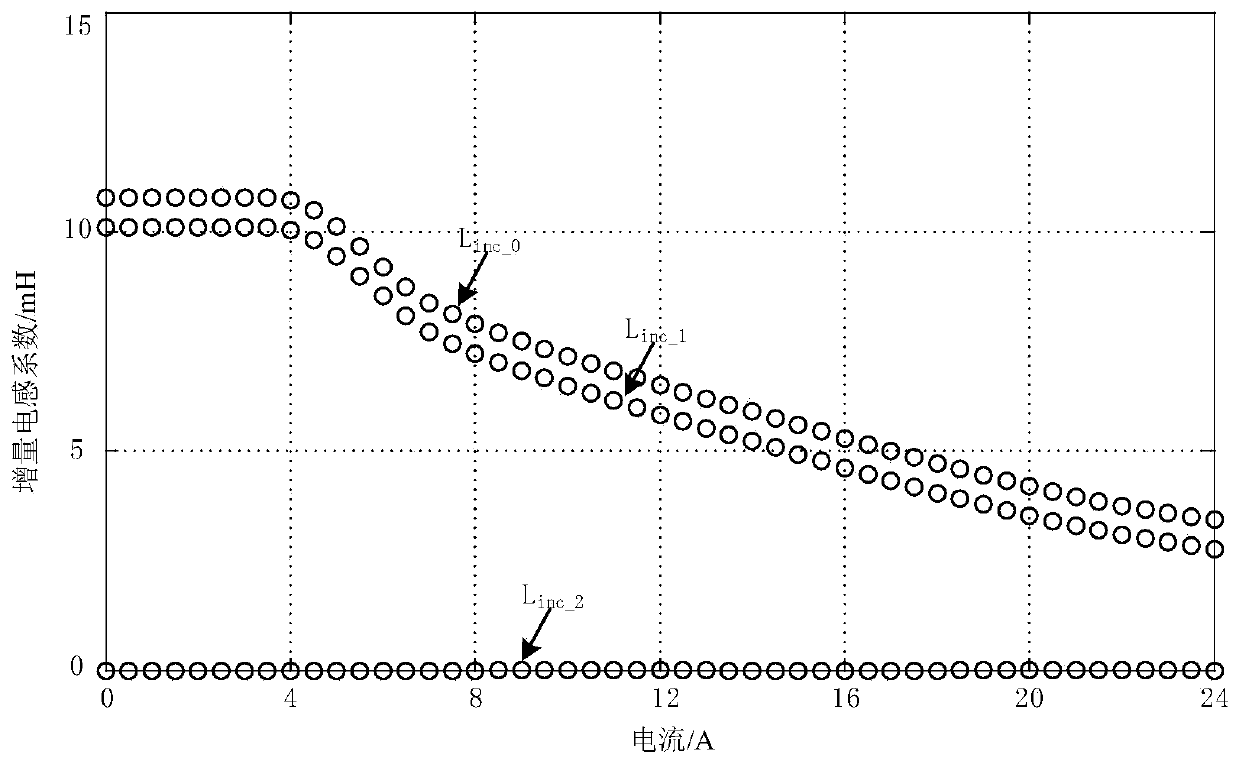

[0044] The three positions are the three special positions of each phase incremental inductance, as attached figure 1 shown. The curves of the prototype phase incremental inductance changing with the phase current at three special positions are attached figure 2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com