Three-dimensional operation instruction station directional pushing system and method for ship production workshop

A technology for work instructions and production workshops, applied in transmission systems, vehicle components, vehicle wireless communication services, etc., can solve problems affecting operation efficiency and quality, restricting production efficiency, and low response to modification, so as to save operating time and Production cost, on-site labor dispatching is simple and efficient, and the effect of simple and fast deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

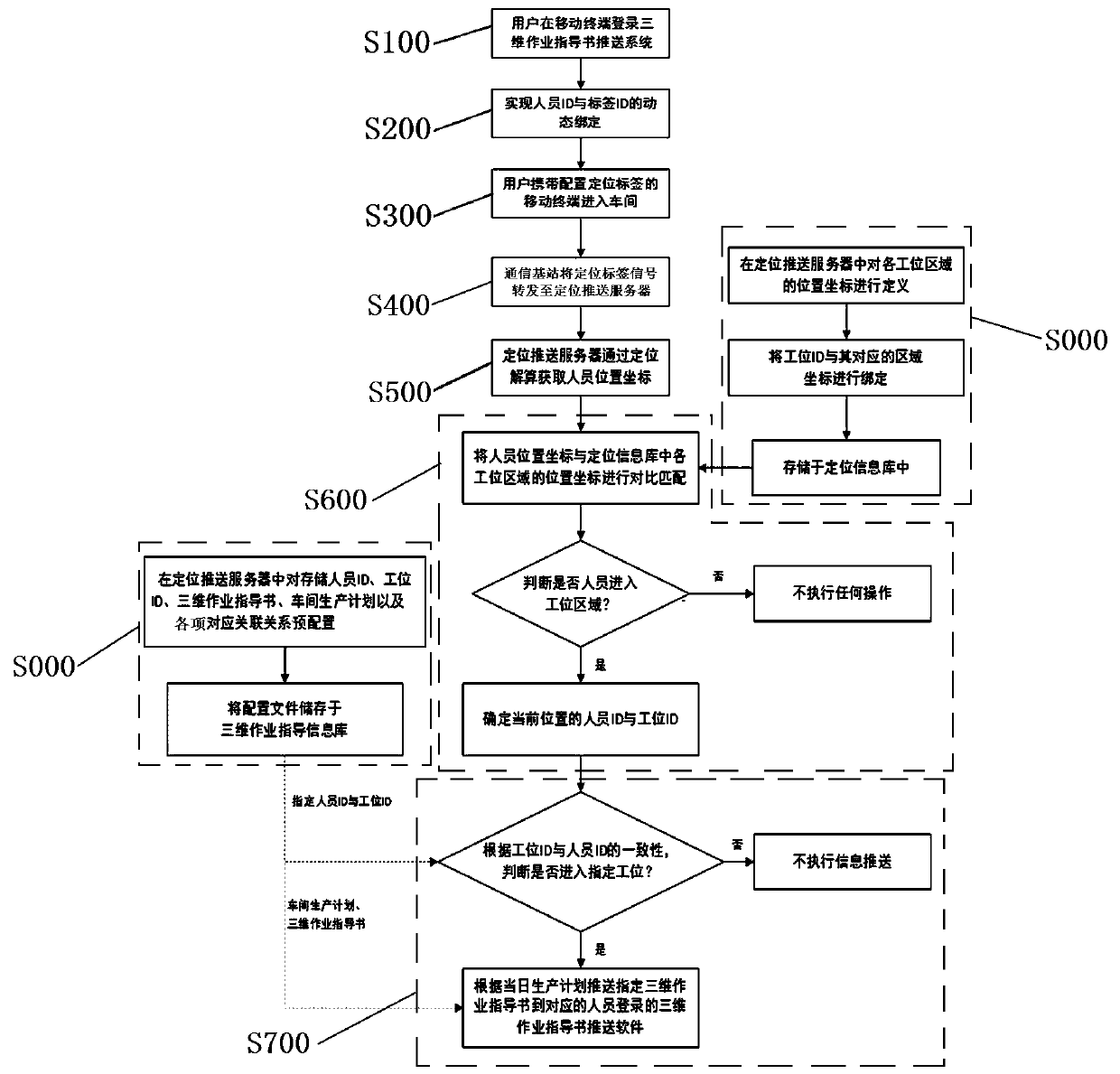

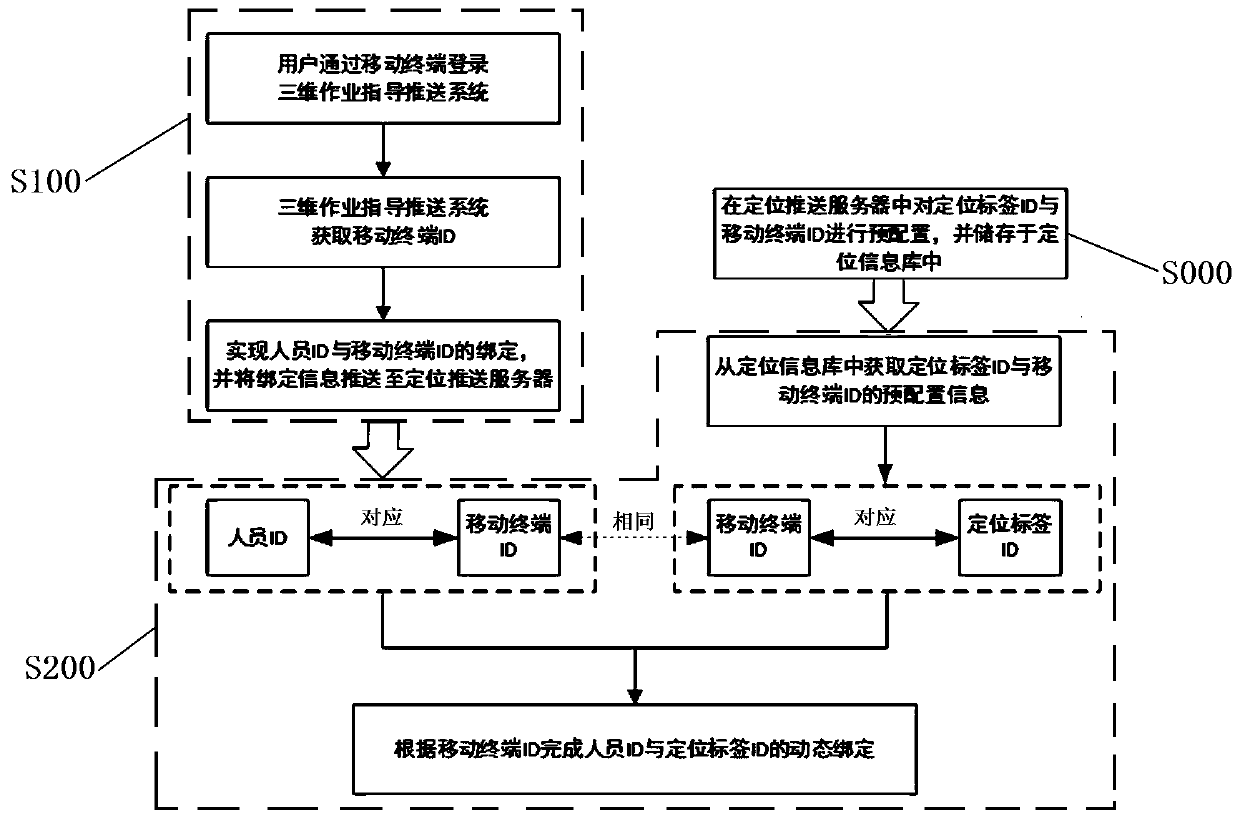

[0053] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

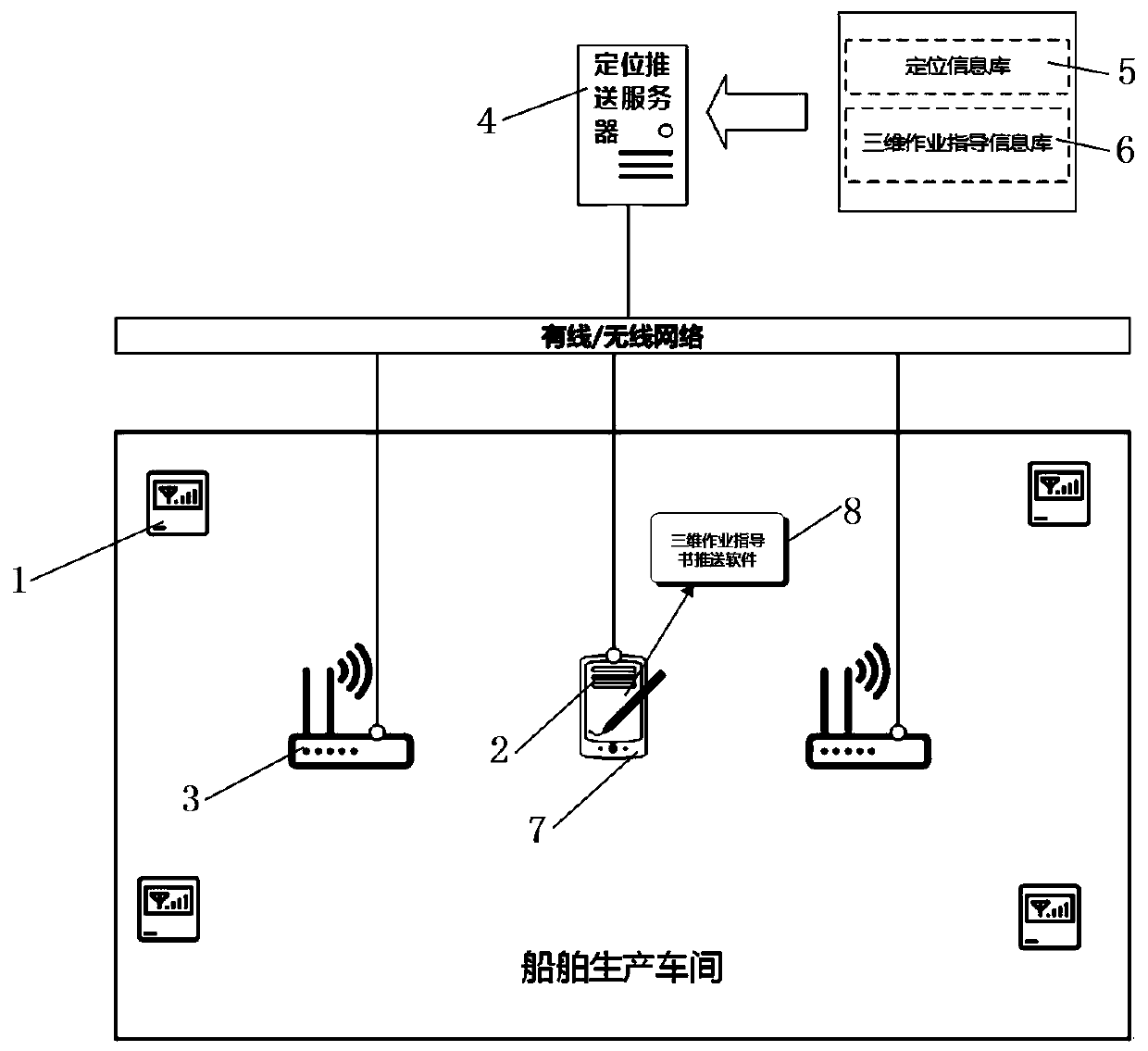

[0054] see figure 1 , a three-dimensional operation instruction station directional push system in a ship production workshop, comprising a plurality of positioning base stations 1, a positioning label 2, a plurality of communication base stations 3, a positioning push server 4, a positioning information library 5, and a three-dimensional operation instruction information library 6 , Mobile terminal 7, 3D operation instruction push software 8.

[0055] The plurality of positioning base stations 1 are fixed at appropriate positions in the ship produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com