Clean extraction process of chondroitin and high-quality type II collagen coproduction using pig and cattle nasal bones

A production process and extraction process technology, applied in the field of clean extraction process, can solve the problems of high production cost, reduced purity, low content of enzymatic hydrolysis liquid phase, etc., and achieve the effects of qualified hygienic index, bright product color, and avoiding degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make those skilled in the art more clear and definite the technical solution of the present invention, the following in conjunction with the attached Figure 1-4 The technical solutions of the present invention are described in detail, but the embodiments of the present invention are not limited thereto.

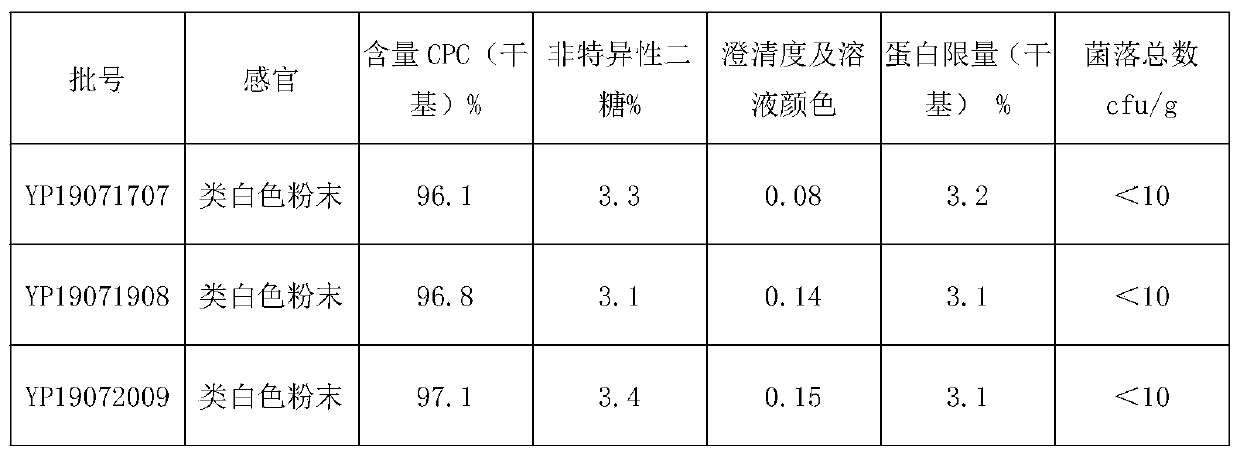

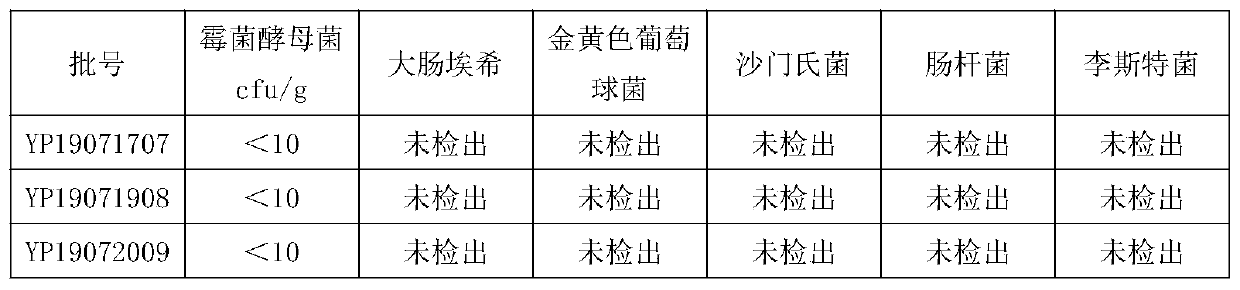

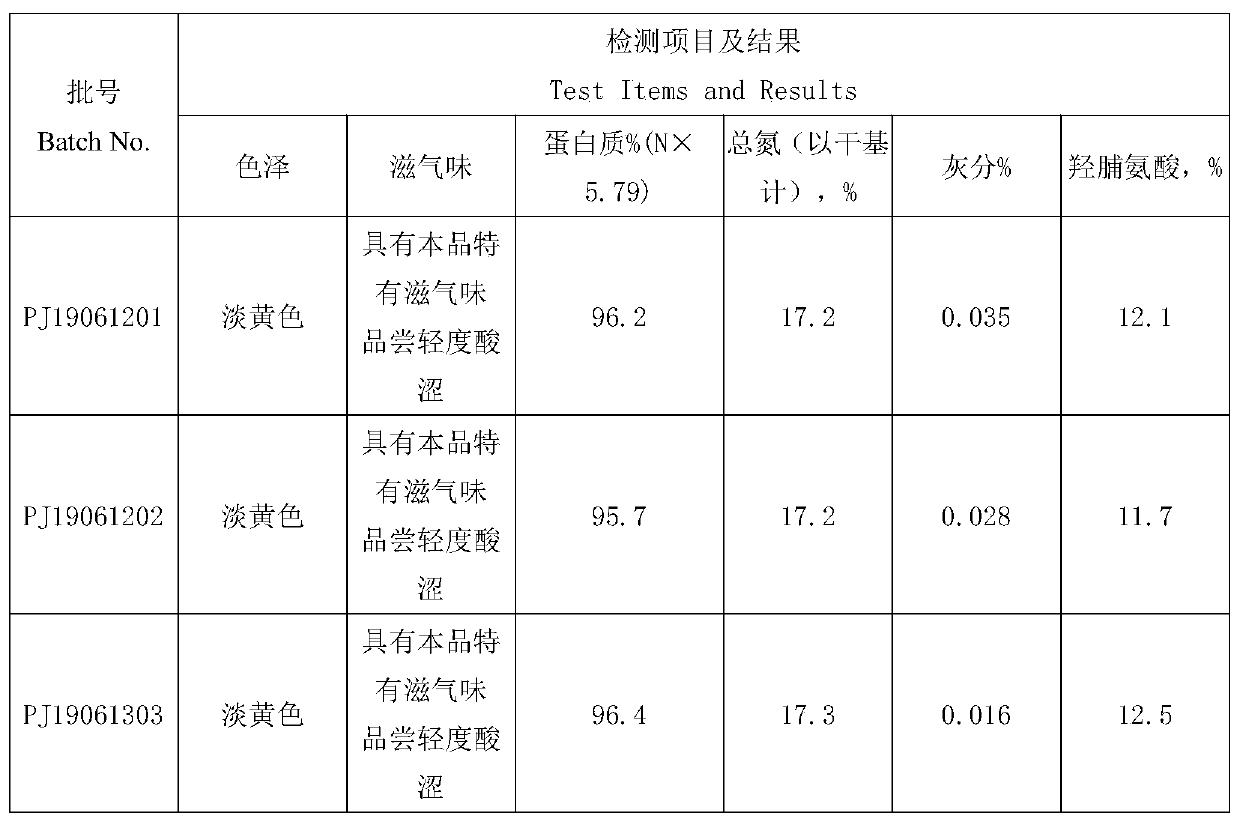

[0027] A clean extraction process for producing chondroitin and co-producing high-quality type Ⅱ collagen from pig and bovine nasal bones, characterized in that it includes a chondroitin production process route and a high-quality type Ⅱ collagen peptide production process route, and the chondroitin production process Route: pig and bovine nose bones→broken into standard bone particles→adding water to soak and expand→using lye to adjust the conductivity of the feed solution, temperature control→leaching→solid-liquid separation→adding biological compound enzyme→filtration→membrane separation→alcohol precipitation→alcohol Washing→vacuum drying→crushing→mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com