Multifunctional composite material, polyether and preparation method and application thereof

A composite material and multi-functional technology, applied in chemical instruments and methods, carbon compounds, polyurea/polyurethane coatings, etc., can solve problems such as distribution, low degree of grafting, and phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

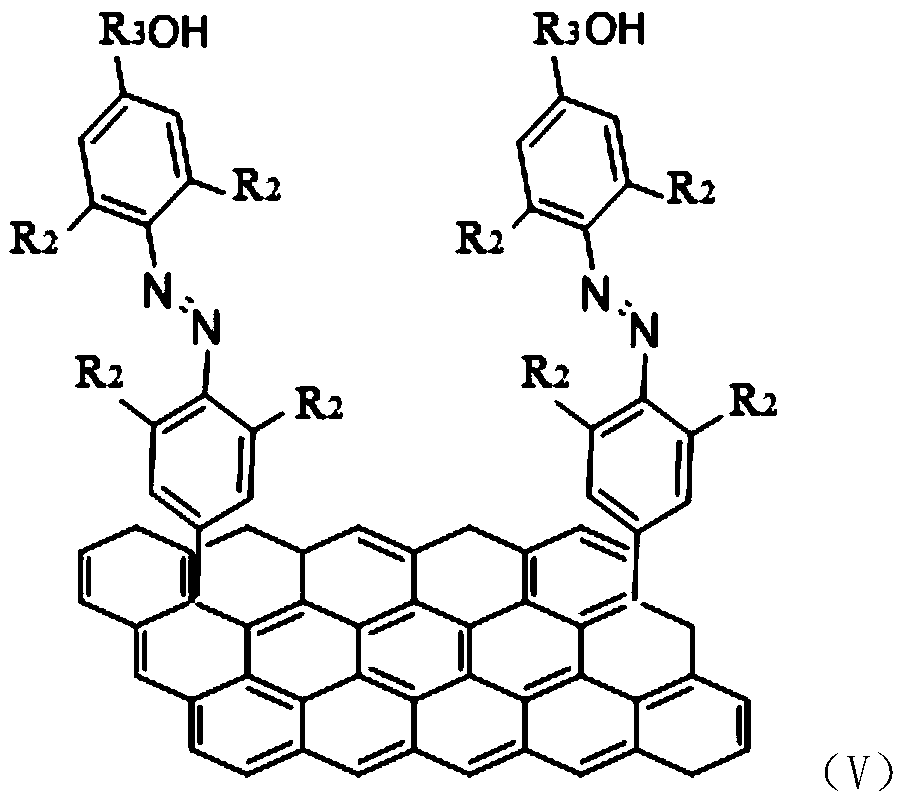

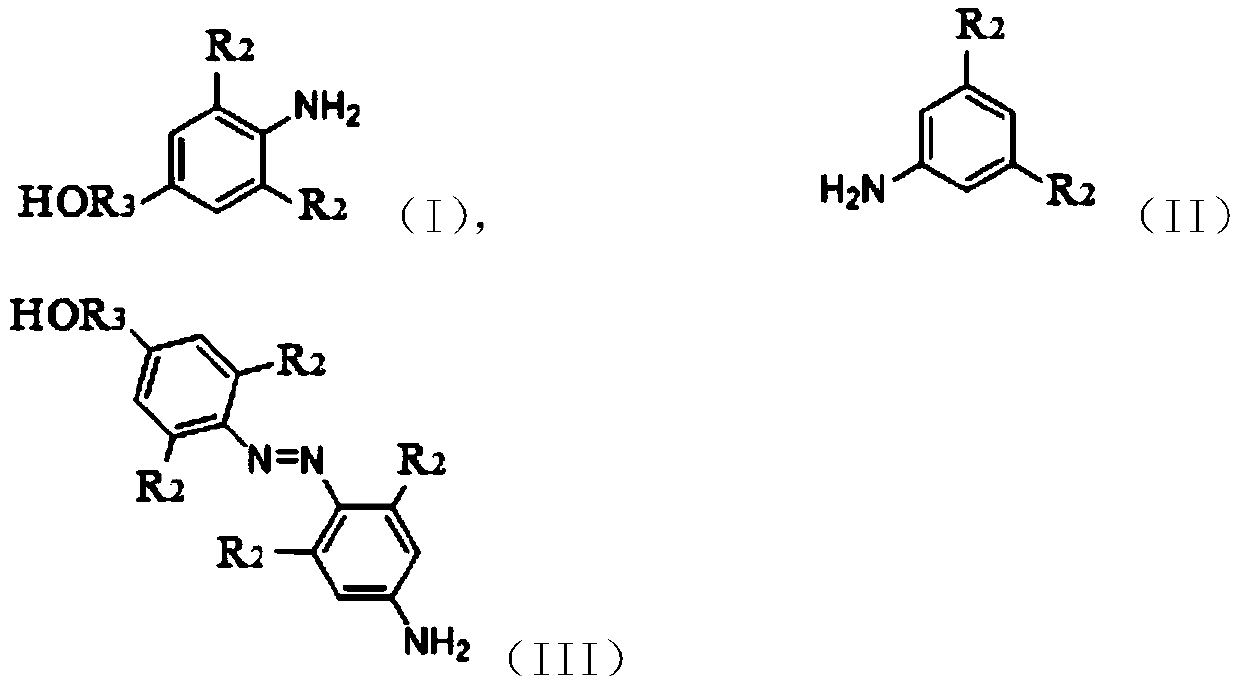

[0052] 1. Synthesis of 2,2',6,6'-tetrafluoro-4-amino-4'hydroxyazobenzene (AZO-1): Weigh 10mol of 3,5-difluoro-4-aminophenol (1450g) and dissolve In 25mol of HCl solution (concentration 38%), it is recorded as A1. Weigh 10mol of NaNO 2 (690g) was dissolved in 5000mL deionized water, and the NaNO 2 Slowly added dropwise to A1. Keep the temperature at 0-5°C, stir and react for 30 minutes to obtain diazonium salt solution B1, weigh 10mol 3,5-difluoroaniline (1290g) and dissolve it in 5000mL of water / acetone with a volume ratio of 5:1 at 0-5°C solution, solution B1 was slowly added dropwise to the solution, using saturated NaHCO 3 The pH of the aqueous solution was adjusted to about 6, and the reaction time was 6h. After the reaction, the product AZO-1 was obtained by recrystallization with ethanol / water (volume ratio 1:1). 19 F NMR (376 MHz, DMSO-d6): δ = -121.33 (s, 4F; Ar-F). HRMS-ESI: m / z: 285.0522 (calcd. for [M+H]+, 285.0525).

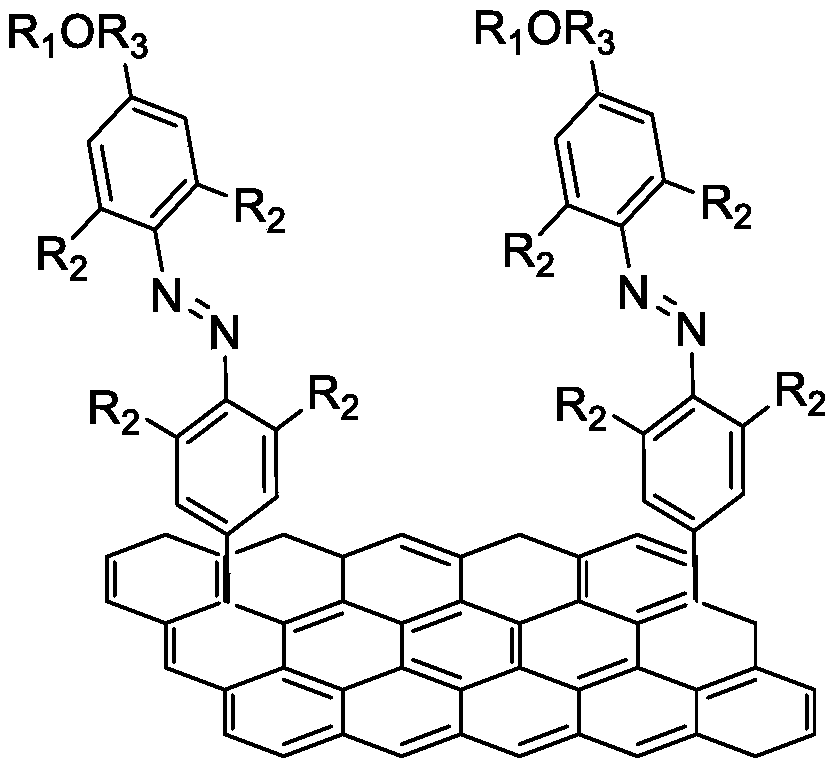

[0053] 2. Multifunctional composite mate...

Embodiment 2

[0056] 1. Synthesis of 2,2',6,6'-tetrabromo-4-amino-4'hydroxyazobenzene (AZO-2): Weigh 10mol 3,5-dibromo-4aminophenol (2670g) and dissolve it in 30molHCl In the solution (concentration 38%), record it as A2. Weigh 11mol NaNO 2 (759g) was dissolved in deionized water, and the NaNO 2 Slowly added dropwise to A2. Keep the temperature at 0-5°C, stir and react for 45 minutes to obtain diazonium salt solution B2. Weigh 10mol of 3,5-dibromoaniline (2510g) and dissolve it in a water / acetone mixed solution with a volume ratio of 5:1 at 0-5°C, slowly add solution B2 to the solution, and use saturated NaHCO 3 The pH of the aqueous solution was adjusted to about 6.5, and the reaction time was 7h. After the reaction, the product AZO-2 was obtained by recrystallization with ethanol / water (volume ratio 1:1). HRMS-ESI: m / z: 528.7279 (calcd.for[M+H] + ,528.7282).

[0057] 2. Multifunctional composite material: weigh 1mol of AZO-2 and 1.1mol of NaNO 2 Add it into a flask containing 500 ...

Embodiment 3

[0060] The synthesis of 1.2,2',6,6'-tetramethoxy-4-amino-4'hydroxy azobenzene (AZO-3): Weigh 10mol 3,5-dimethoxy-4 aminophenol ( 1690g) was dissolved in 40mol HCl (concentration 38%) solution, recorded as A3. Weigh 21molNaNO 2 (1449g) was dissolved in deionized water, and the NaNO 2 Slowly added dropwise to A3. Keep the temperature at 0-5°C, stir and react for 60 minutes to obtain diazonium salt solution B3. Weigh 18mol of 3,5-dimethoxyaniline (2754g) and dissolve it in a water / acetone mixed solution with a volume ratio of 5:1 at 0-5°C, slowly add solution B3 to the solution, and use a saturated NaHCO 3 The pH of the aqueous solution is adjusted to 5-7, and the reaction time is 8 hours. After the reaction, the product AZO-3 was obtained by recrystallization with ethanol / water (volume ratio 1:1). HRMS-ESI: m / z: 333.1324 (calcd. for [M+H]+, 333.1325).

[0061] 2. Multifunctional composite material: weigh 1mol of AZO-3 and 1.18mol of NaNO 2 Add it into a flask containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com