Coal ash slag cooling and dischargging system

A technology for cooling exhaust and coal ash, which is applied in the direction of gasification process, petroleum industry, and manufacture of combustible gas, etc. It can solve the problems of increasing equipment and raw coal input costs, clogging of circulating pumps and heat exchangers, and high overall height of slag discharge equipment, etc. problems, to achieve the effect of promoting the reaction of carbon and water vapor, reducing input costs, and increasing the content of effective gas components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

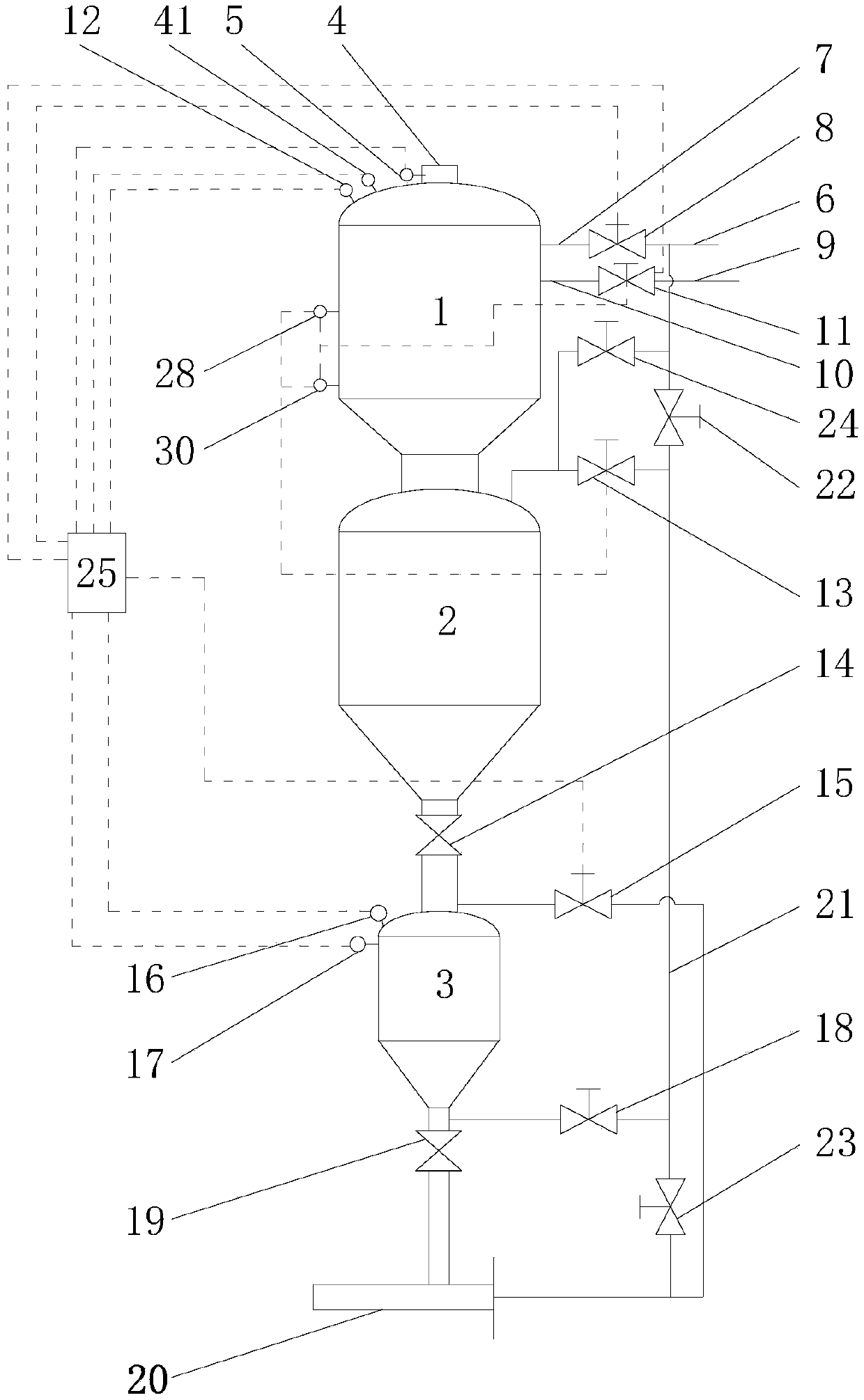

[0023] Such as Figure 1-3 As shown, a coal ash cooling slag discharge system includes a cold slag tank 1, a slag collection tank 2 and a slag discharge tank 3,

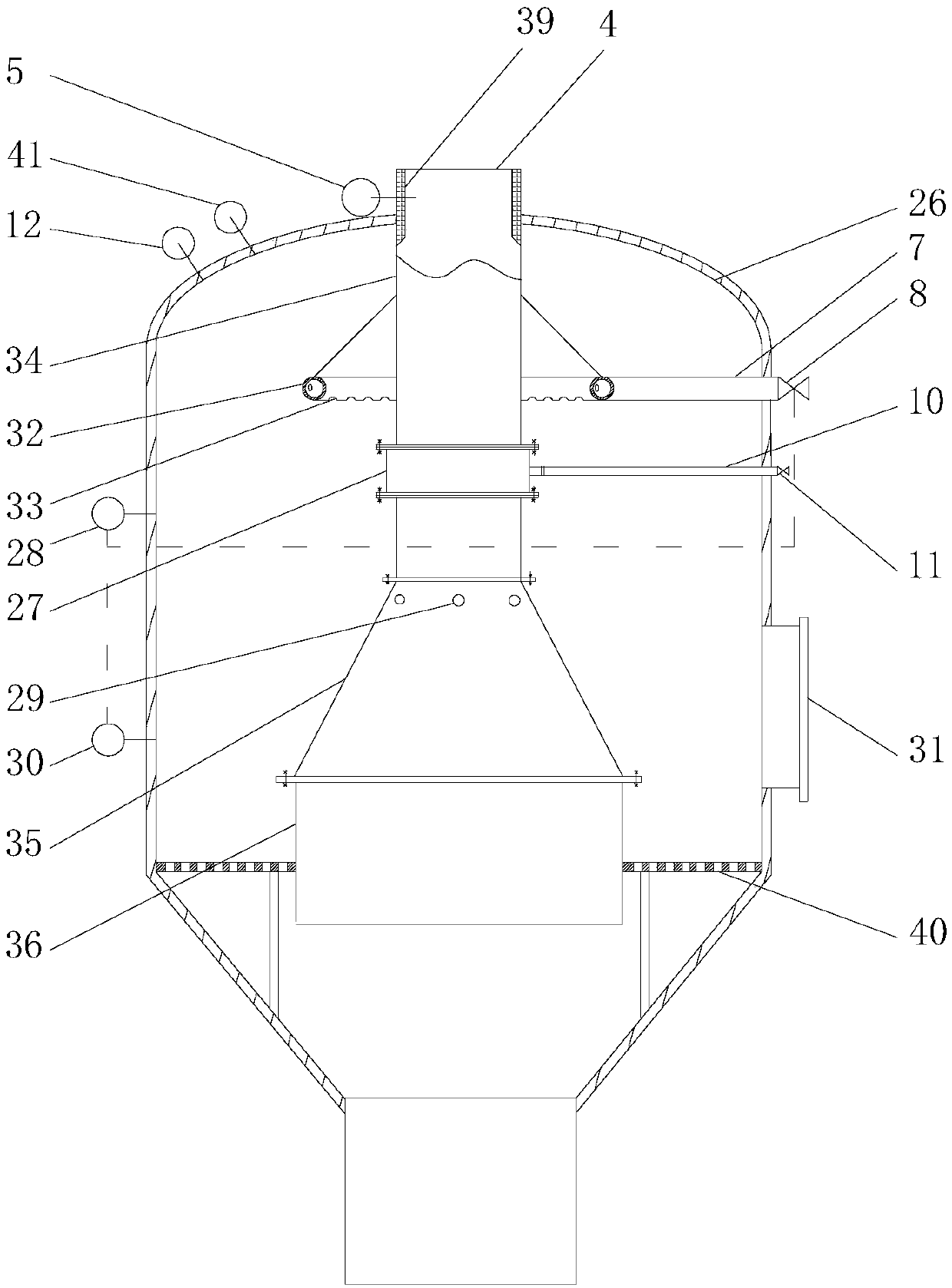

[0024] The cold slag tank 1 includes a tank body 26, and an ash and slag pipe 4 is vertically arranged in the middle of the tank body 26. The top of the ash slag pipe 4 extends to the outside of the top of the tank body 26, and the outlet of the ash slag pipe 4 extends to the cold slag tank. 1, a passage is formed between the bottom end of the ash pipe 4 and the bottom end of the tank body 26, and the ash slag falls into the tank body 26 through the ash pipe 4 for cooling.

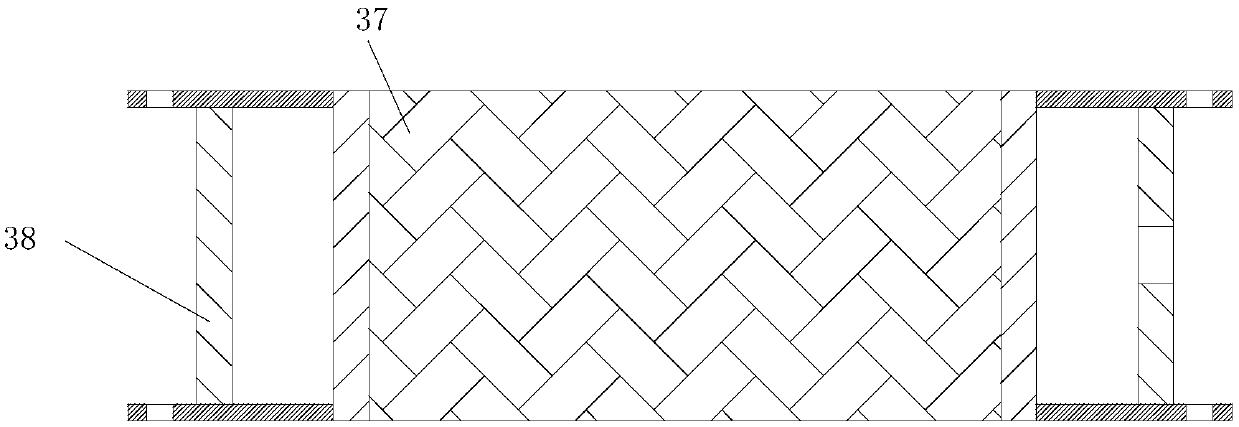

[0025] The ash pipe 4 comprises a straight pipe heat exchange section 34, a diameter-expanding pipe vaporization section 35 and a straight pipe slag discharge section 36 connected successively from top to bottom. The diameter of the heat exchange section 34 of the tube can limit the diffusion of high-temperature ash in the cooling water, and can...

Embodiment 2

[0046] A kind of coal ash cooling and slagging method carried out by utilizing a kind of coal ash cooling and slag discharging system in embodiment 1, it comprises the following steps: (1) primary cooling of cooling gas, (2) secondary cooling of steam, (3) ) cooling water for three times cooling, (4) slag feeding and slag discharge of the slag discharge tank; wherein,

[0047] (1) Primary cooling of the cooling gas: the 850°C-900°C ash discharged from the fluidized bed gasification furnace enters the ash pipe 4, and the cooling gas carbon dioxide enters the pipe body 38 of the gas distribution pipe 27 through the gas filling pipe 10, and then passes through the sintering The metal filter element 37 sprays out evenly to cool the ash in the ash pipe 4 once. The ash cooled to 450°C-550°C moves down along the ash pipe 4, and the carbon dioxide after heat exchange with the ash flows along the ash pipe. Pipe 4 moves upwards into the fluidized bed gasifier; carbon dioxide is used ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com