Preparation method of high-strength 2000-series aluminum alloy based on selective laser melting forming technology

A laser melting and high-strength technology, which is applied in the direction of improving process efficiency, additive manufacturing, and improving energy efficiency, can solve problems such as poor weldability, limited industrial applications, and alloys that are prone to thermal cracks, and achieve high density and improved Solid solution strengthening effect, effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

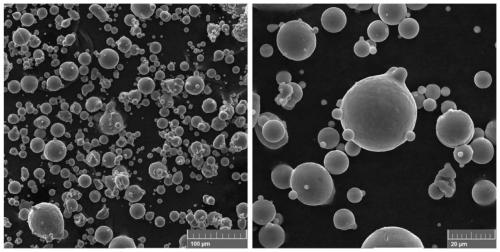

[0027]Prepare the high-strength 2000-series aluminum composite components for 3D printing in the present invention, in terms of mass percentage: Cu: 5.0%, Li: 0.5%, Mg: 0.2%, Zr: 1%, Ti: 0.5%, and the balance for Al. The preparation method of the above-mentioned aluminum alloy powder is as follows: (1) raw material smelting, each element is weighed in proportion to the pure metal block raw material and placed in a vacuum induction furnace for heating and melting; (2) atomization powder making, the above-mentioned pre-alloyed metal after melting Transfer to the atomization tank, use helium to atomize and make powder; (3) Powder sieving: The above-mentioned pre-alloyed metal powder is screened to obtain a metal powder with an average particle size of 38 μm, and the particle size range is 11 μm ~68 μm. (4) Heat preservation and drying: put the above-mentioned sieved powder into a drying oven, heat preservation time is 12 hours, and heat preservation temperature is 95°C.

[0028...

Embodiment 2

[0031] Prepare the high-strength 2000 series aluminum composite components for 3D printing in the present invention, in terms of mass percentage: Cu: 3.5%, Li: 0.5%, Mg: 0.5%, Zr: 2%, Ti: 0.8%, and the balance for Al. The preparation method of the above-mentioned aluminum alloy powder is as follows: (1) raw material smelting, each element is weighed in proportion to the pure metal block raw material and placed in a vacuum induction furnace for heating and melting; (2) atomization powder making, the above-mentioned pre-alloyed metal after melting Transfer to the atomization tank, use helium to atomize and make powder; (3) Powder sieving: The above-mentioned pre-alloyed metal powder is screened to obtain a metal powder with an average particle size of 38 μm, and the particle size range is 11 μm ~68 μm. (4) Heat preservation and drying: put the above-mentioned sieved powder into a drying oven, heat preservation time is 12 hours, and heat preservation temperature is 95°C.

[003...

Embodiment 3

[0035] Prepare the high-strength 2000-series aluminum composite components for 3D printing in the present invention, in terms of mass percentage: Cu: 4%, Li: 0.7%, Mg: 1%, Zr: 1.5%, Ti: 0.7%, and the balance for Al. The preparation method of the above-mentioned aluminum alloy powder is as follows: (1) raw material smelting, each element is weighed in proportion to the pure metal block raw material and placed in a vacuum induction furnace for heating and melting; (2) atomization powder making, the above-mentioned pre-alloyed metal after melting Transfer to the atomization tank, use helium to atomize and make powder; (3) Powder sieving: The above-mentioned pre-alloyed metal powder is screened to obtain a metal powder with an average particle size of 38 μm, and the particle size range is 11 μm ~68 μm. (4) Heat preservation and drying: put the above-mentioned sieved powder into a drying oven, heat preservation time is 12 hours, and heat preservation temperature is 95°C.

[0036]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com