Rolling transmission device plated with super-lubricative solid thin film

A transmission, super-lubrication technology, applied in the field of bearings, can solve problems such as poor process effect, and achieve the effects of increasing stability, reducing energy loss, and reducing friction torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

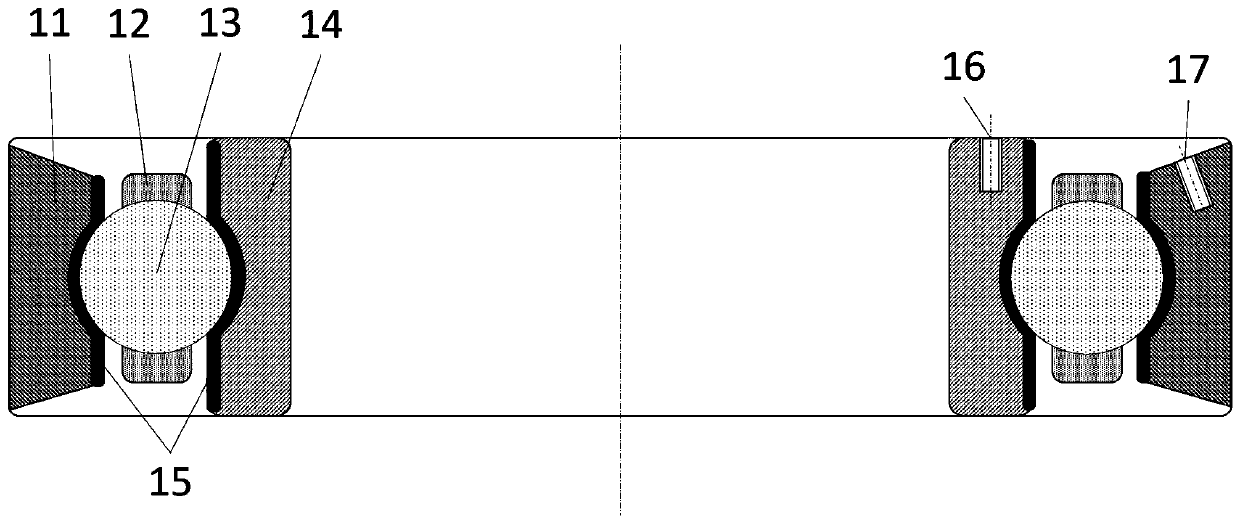

Embodiment 1

[0032] Such as figure 1 As shown, a ball bearing for spacecraft coated with a super-lubricating solid film, the ball bearing is composed of an outer ring 11, a retainer 12, a ball 13 and an inner ring 14; in this embodiment, the outer surface of the inner ring 14 and the outer ring 11 The inner surface is coated with a-C:H based super lubricating solid film. The outer ring 11 and the inner ring 14 are provided with conductive screw holes 16 and 17 . The materials of each component are: the outer ring 11 is 30CrMnSi, the retainer 12 is PTFE, the ball 13 is 9Cr18 stainless steel, and the inner ring 14 is 30CrMnSi. The preparation process of a-C:H-based super lubricating solid film 15 is as follows:

[0033] The a-C:H-based super-lubricating solid film is prepared by reactive magnetron sputtering technology. First, stainless steel screws are used to connect with conductive threaded holes, so that the parts to be coated are fixed on the workpiece table; Through the design of th...

Embodiment 2

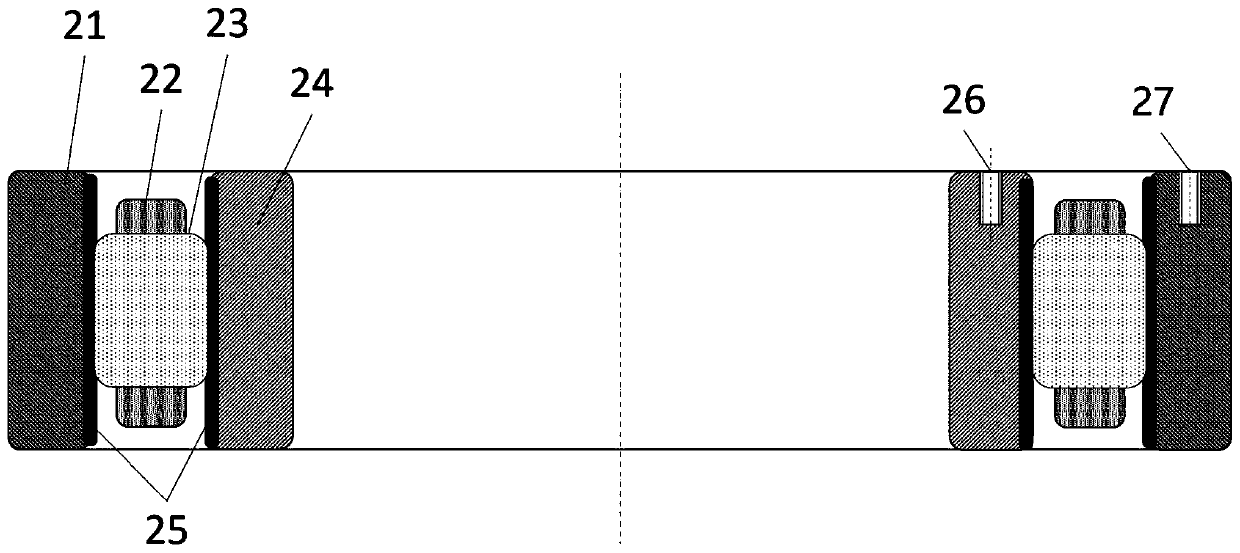

[0038] Such as figure 2 As shown, a roller bearing for a spacecraft coated with a super-lubricating solid film, the roller bearing is composed of an outer ring 21, a retainer 22, a roller 23 and an inner ring 24; in this embodiment, the inner surface of the outer ring 21 and The outer surface of the inner ring 24 is coated with an a-C:H based super lubricating solid film 25 . The outer ring 21 and the inner ring 24 are provided with conductive screw holes 26 and 27 . Among them, the materials of each component are: the outer ring 21 is 30CrMnSi, the cage 22 is PTFE, the roller 23 is 9Cr18 stainless steel, and the inner ring 24 is 30CrMnSi. a-C: H-based super lubricating solid film, the preparation process is as follows:

[0039] The a-C:H-based super-lubricating solid film is prepared by reactive magnetron sputtering technology. First, stainless steel screws are used to connect with conductive threaded holes, so that the parts to be coated are fixed on the workpiece table; ...

Embodiment 3

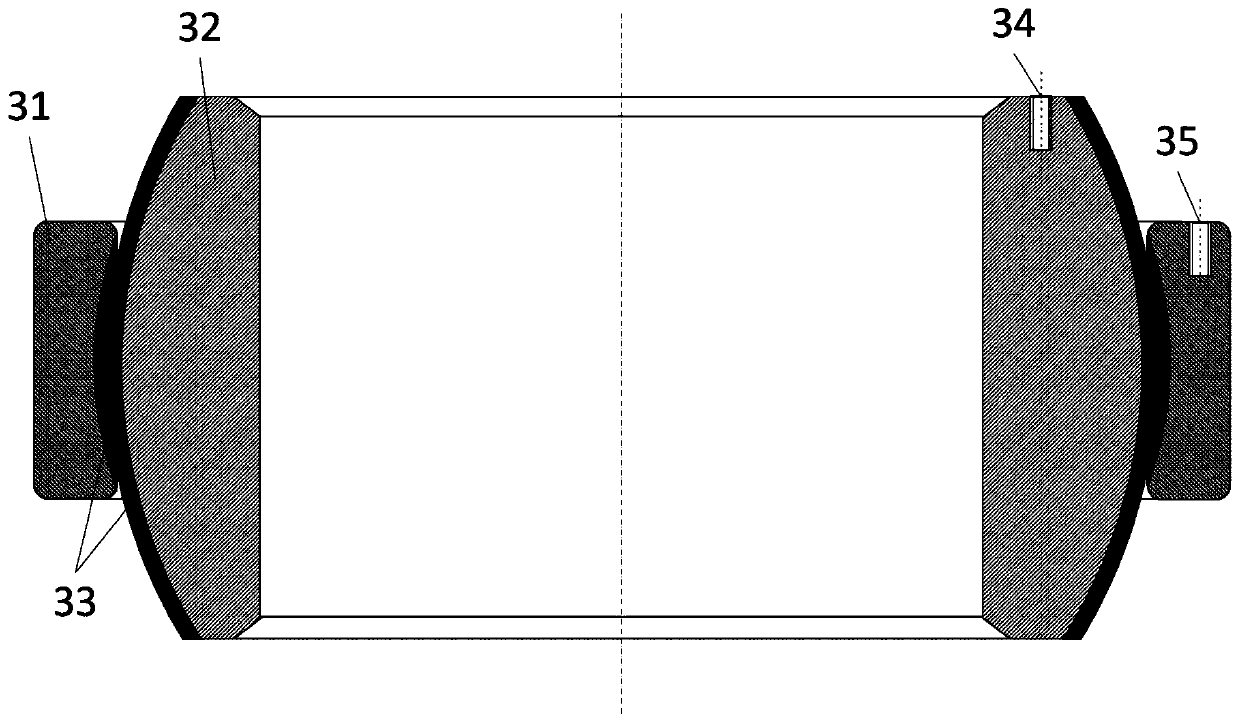

[0044] Such as image 3 As shown, a joint bearing for spacecraft coated with a super-lubricating solid film, the joint bearing is composed of an outer ring 31 and an inner ring 32; in this embodiment, the outer ring 31 and the inner ring 32 are coated with a-C:H-based super Lubricate the solid film 33 . The outer ring 31 and the inner ring 32 are provided with conductive screw holes 34 and 35 . The materials of each component are: the outer ring 31 is 30CrMnSi, and the inner ring 32 is 9Cr18. The preparation process of a-C:H base superlubricating solid film is as follows:

[0045] The a-C:H-based super-lubricating solid film is prepared by reactive magnetron sputtering technology, and stainless steel screws are used to connect with conductive threaded holes, so that the parts to be coated are fixed on the workpiece table; Connectivity, through the design of the size of the conductive threaded hole, the material of the conductive screw, and the material of the wire strap, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com