Package and film

A packaging and film technology, applied in packaging, wrapping paper, packaged food, etc., can solve problems such as not being able to expand freely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

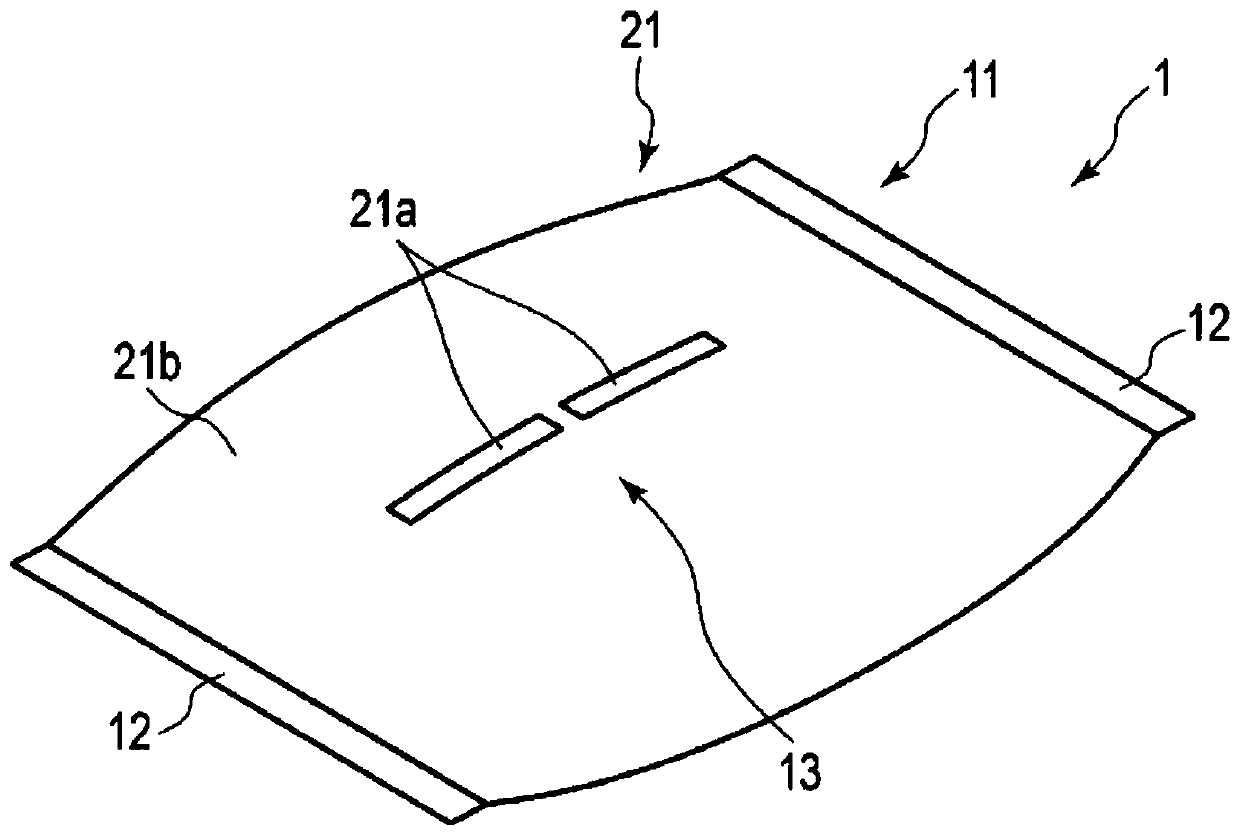

[0031] use Figure 1 to Figure 3 The package 1 using the film 11 according to the first embodiment of the present invention will be described.

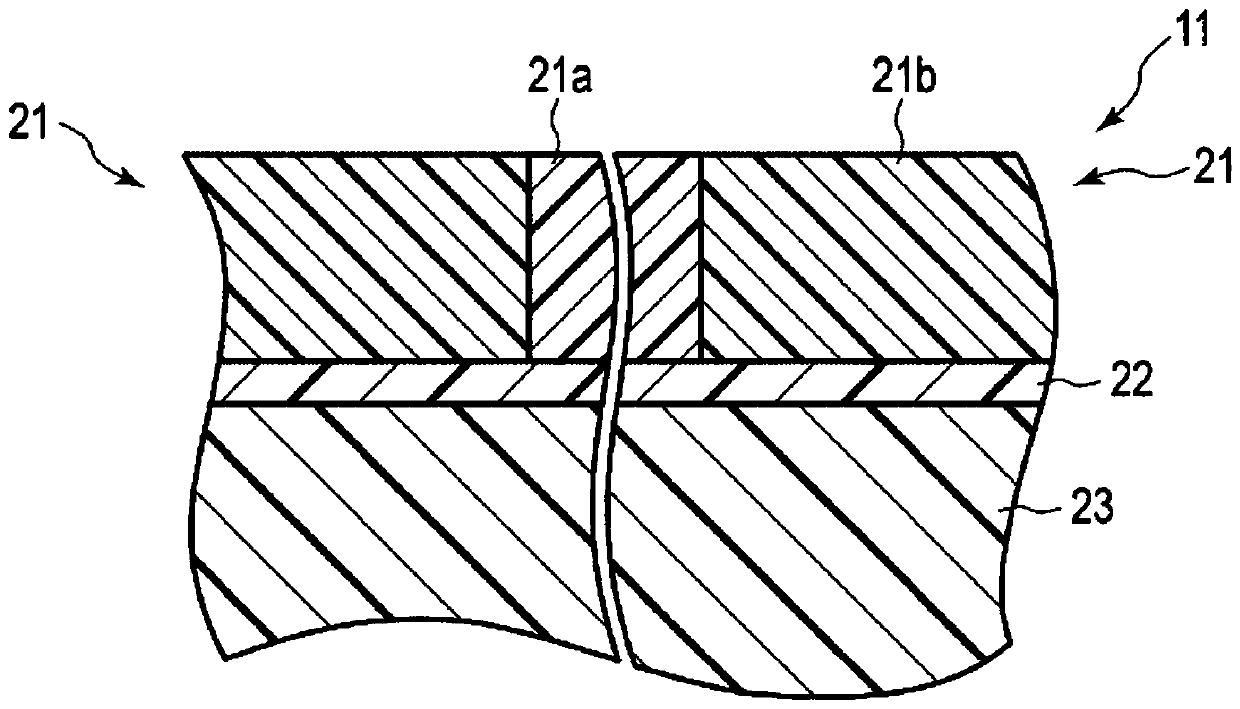

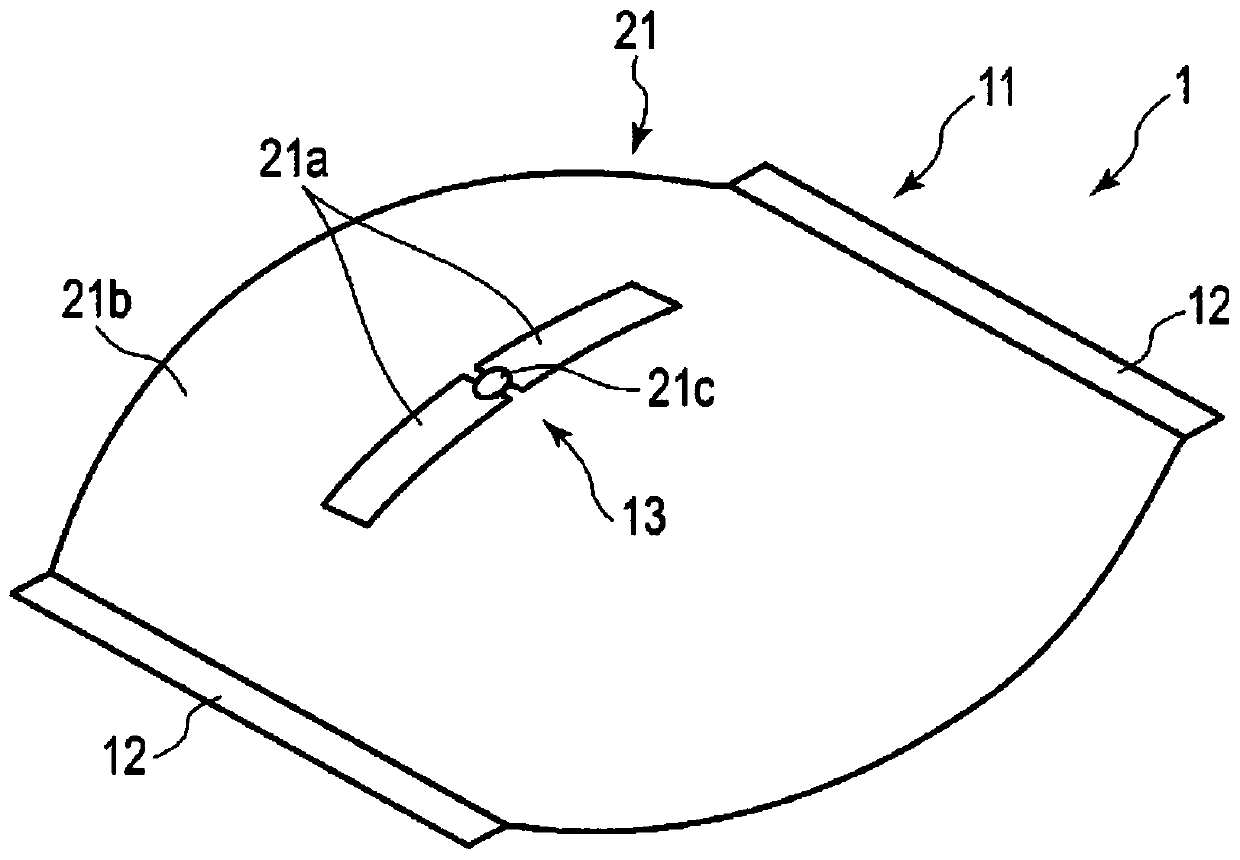

[0032] figure 1 It is a perspective view showing the structure of the package 1 according to the first embodiment of the present invention, figure 2 It is a cross-sectional view schematically showing the layer structure of the film 11 used in the package 1 . image 3 It is a perspective view showing a state heated by a microwave oven as an example of using the package body 1 .

[0033] Such as figure 1 As shown, the packaging body 1 is a packaging container for microwave oven heating formed by forming a film 11 having a multilayer structure having a crystalline stretched oriented film 21 on the outer surface side into a bag shape. The package 1 is, for example, a pillow bag configured by accommodating contents in a bag-shaped film 11 and sealing an end portion with a sealing portion 12 .

[0034] As a specific example, the packa...

Embodiment 1

[0069] As Example 1, the following structures were used for the package 1 and the film 11 . As the crystalline stretched oriented film 21, a biaxially stretched PET film (Toyobo Co., Ltd.: E5100) with a thickness of 12 μm was used. In addition, as the sealant film 23 , an LLDPE film (Toyobo Co., Ltd.: L4102) having a thickness of 40 μm was used. As the adhesive layer 22, a polyurethane-based dry lamination adhesive was used, and the crystalline stretched oriented film 21 and the sealant film 23 were bonded together, and aged in a constant temperature bath at 38°C for 3 days to produce up figure 1 Film 11 is shown.

[0070] The position near the center of the upper surface side of the packaging body 1 of the crystalline stretched oriented film 21 of the film 11 was heated by a carbon dioxide laser, as Figure 4 A pair of non-oriented portions 21a are formed as shown. In addition, the non-orientation part 21a is made into a long rectangular shape in one direction, and the le...

Embodiment 2

[0073] The packaging body 1 and the film 11 of Example 2 have the following structures. The materials of the crystalline stretched oriented film 21, the adhesive layer 22, and the sealant film 23, the shape of the non-oriented portion 21a, and the shape of the package 1 were the same as in Example 1, but the pair of non-oriented portions 21a The distance between the opposing short sides (approach pitch) was set to 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com