Straw feed briquetting process

A technology of straw feed and straw, which is applied in the field of straw feed briquetting technology, can solve the problems of straw color turning yellow, long time, loss of nutrients, etc., and achieve the effect of enhancing taste and color, and strong attraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

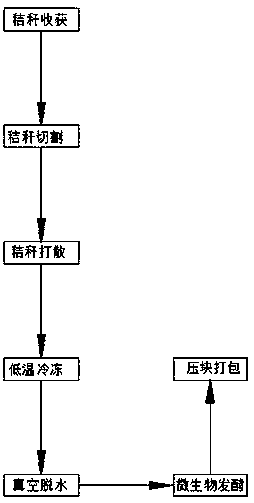

[0019] refer to figure 1 , a straw feed briquetting process, comprising the following steps:

[0020] S1: Straw harvesting, select high-quality straw after harvest, and remove the withered and rotten parts of the straw;

[0021] S2: Straw cutting, the straw is cut into straws of equal length or short length by a cutting machine, and is set aside;

[0022] S3: The straw is scattered, and the cut straw of equal length or short length is added to the kneading machine, and the straw is kneaded to destroy the rough and hard skin and hard stem of the straw, and knead the straw into a filamentous structure;

[0023] S4: Freeze-drying at low temperature, putting the straw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com