Pickling solution prepared by using pickled vegetable processing wastes and method for processing pickled vegetables by pickling solution

A technology of waste and acid staining, applied in the field of pickling liquid and its processing pickles, can solve the problems of complicated steps, long process flow, underutilization, etc., reduce the difficulty of process production and process cost, and avoid complicated steps , enhance the effect of flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

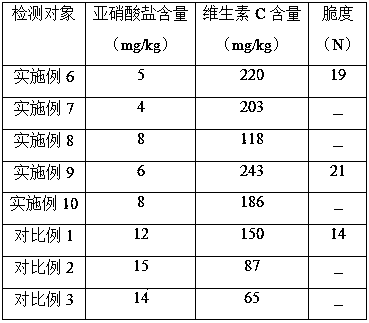

Examples

Embodiment 1

[0024] This embodiment relates to a kind of pickling solution prepared from pickled vegetable processing waste.

[0025] Utilize the waste vegetable leftovers processed by pickles as raw materials, and prepare pickling liquid according to the following steps:

[0026] (1) Preprocessing,

[0027] After cleaning the vegetable scraps, add cold boiled water at a volume ratio of 1:3, and the mass fraction of vitamin C in the vegetable scraps is usually 0.3-0.5‰.

[0028] (2) beating and filtering,

[0029] Put the vegetable leftovers in the fruit and vegetable beater, add cold boiled water for beating treatment, filter the slurry with gauze after beating, and collect the filtered filtrate.

[0030] (3) fermentation,

[0031] The lactic acid bacteria liquid and auxiliary materials are added to the filtrate, and fermented at 30°C for 20 hours to obtain a fermented liquid.

[0032] Among them, the lactic acid bacteria liquid is prepared by suspending the commercial lactic acid bac...

Embodiment 2

[0043] This embodiment relates to a kind of pickling solution prepared from pickled vegetable processing waste.

[0044] Utilize the waste vegetable leftovers processed by pickles as raw materials, and prepare pickling liquid according to the following steps:

[0045] (1) Preprocessing,

[0046] After cleaning the vegetable scraps, add cold boiled water at a volume ratio of 1:5, and the mass fraction of vitamin C in the vegetable scraps is usually 0.3-0.5‰.

[0047] (2) beating and filtering,

[0048] Put the vegetable leftovers in the fruit and vegetable beater, add cold boiled water for beating treatment, filter the slurry with gauze after beating, and collect the filtered filtrate.

[0049] (3) fermentation,

[0050] Add lactic acid bacteria liquid and auxiliary materials to the filtrate, and ferment at 37° C. for 30 hours to obtain a fermented liquid.

[0051]Among them, the lactic acid bacteria liquid is prepared by suspending the commercial lactic acid bacteria solid...

Embodiment 3

[0062] This embodiment relates to a kind of pickling solution prepared from pickled vegetable processing waste.

[0063] Utilize the waste vegetable leftovers processed by pickles as raw materials, and prepare pickling liquid according to the following steps:

[0064] (1) Preprocessing,

[0065] After cleaning the vegetable scraps, add cold boiled water at a volume ratio of 1:4. The mass fraction of vitamin C in the vegetable scraps is usually 0.3-0.5‰.

[0066] (2) beating and filtering,

[0067] Put the vegetable leftovers in the fruit and vegetable beater, add cold boiled water for beating treatment, filter the slurry with gauze after beating, and collect the filtered filtrate.

[0068] (3) fermentation,

[0069] The lactic acid bacteria liquid and auxiliary materials are added to the filtrate, and fermented at 35°C for 24 hours to obtain a fermented liquid.

[0070] Among them, the lactic acid bacteria liquid is prepared by suspending the commercial lactic acid bacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com