Sea surface spilled oil rapid separation and recovery system

A technology for separation and recovery of oil spilled on the sea surface, applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as pipeline leakage, crude oil leakage, floating, etc., achieve good cost investment, extend service life and service life, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

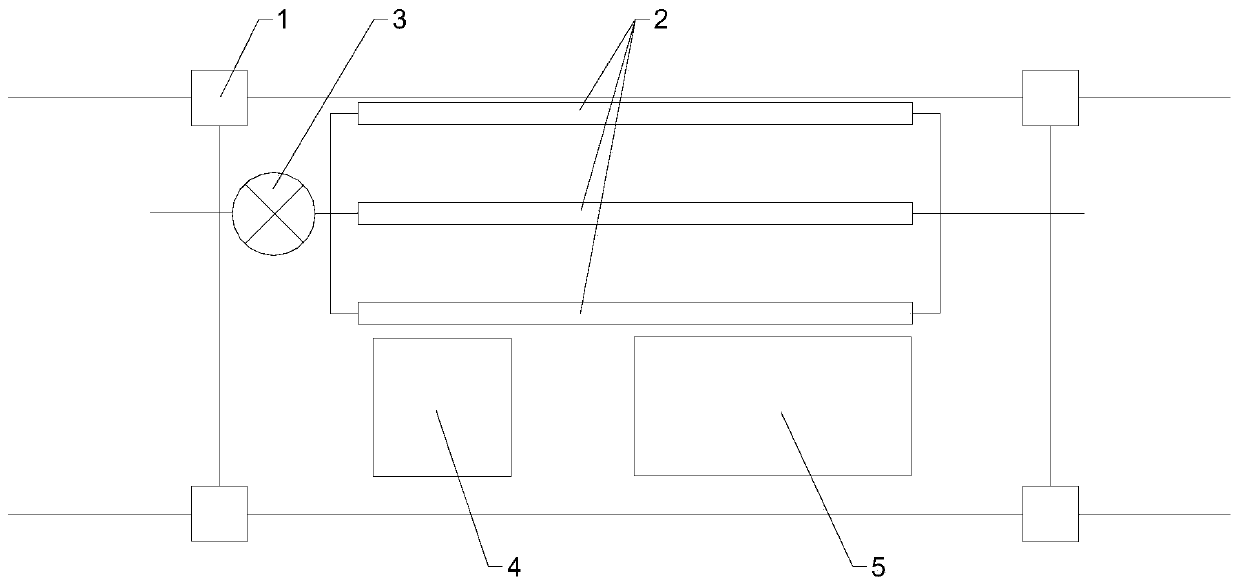

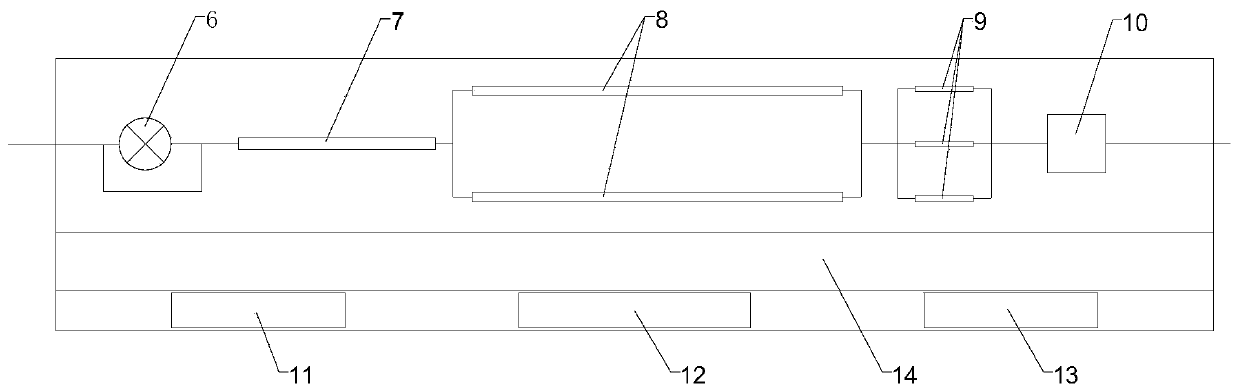

[0038] This embodiment provides a rapid separation and recovery system for oil spilled on the sea surface, which is composed of an oil spill recovery module installed on a buoy and a recovery object separation module installed on an engineering ship, and the oil spill recovery module and the recovery object separation module are connected through pipelines ;

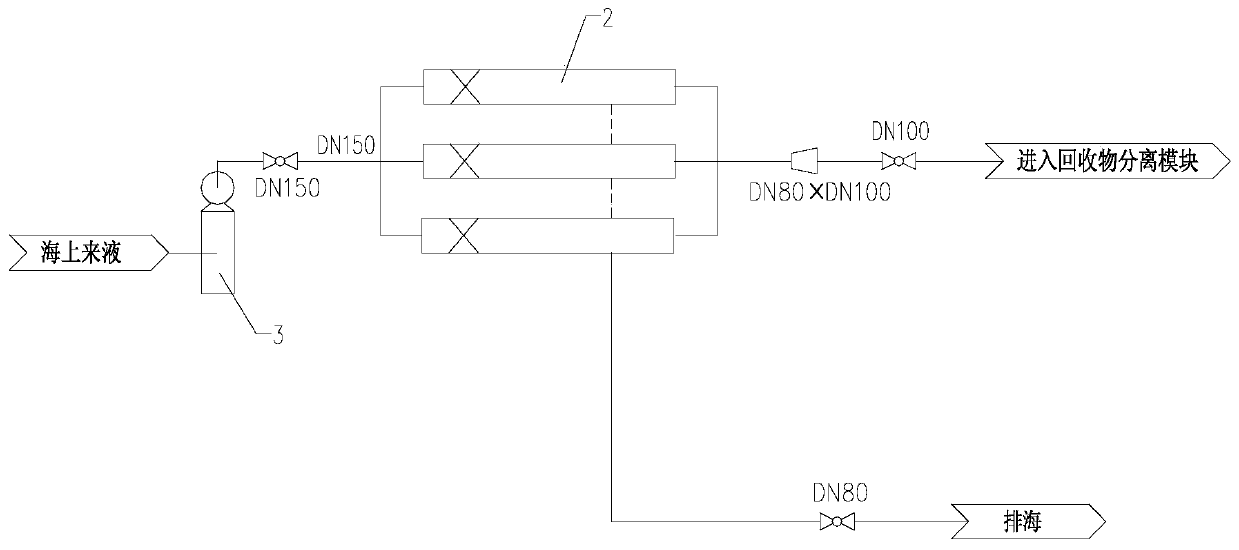

[0039] The oil spill recovery module includes a submersible pump 3, a vortex separator-2, a signal control device 4, and a traction system 5; the submersible pump 3 is connected to the vortex separator-2 through a pipeline and placed side by side on the side of the buoy . The flow rate of submersible pump 3 is 300m 3 / h, which can meet the needs of large processing capacity; the vortex separator-2 is provided with three and arranged in parallel, which can adjust the processing capacity of the incoming liquid, increase the centrifugal force, and better separate the oil-water mixture. The three vortex separators Separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com