Molecular sieve gas circuit control device and oxygenerator

A technology of gas circuit control and molecular sieve, which is applied in the fields of oxygen preparation, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problems of difficult noise control, high risk of air leakage, complex gas circuit control structure, etc. , to achieve good encapsulation of the gas path structure, reduce the number of joints, and eliminate instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

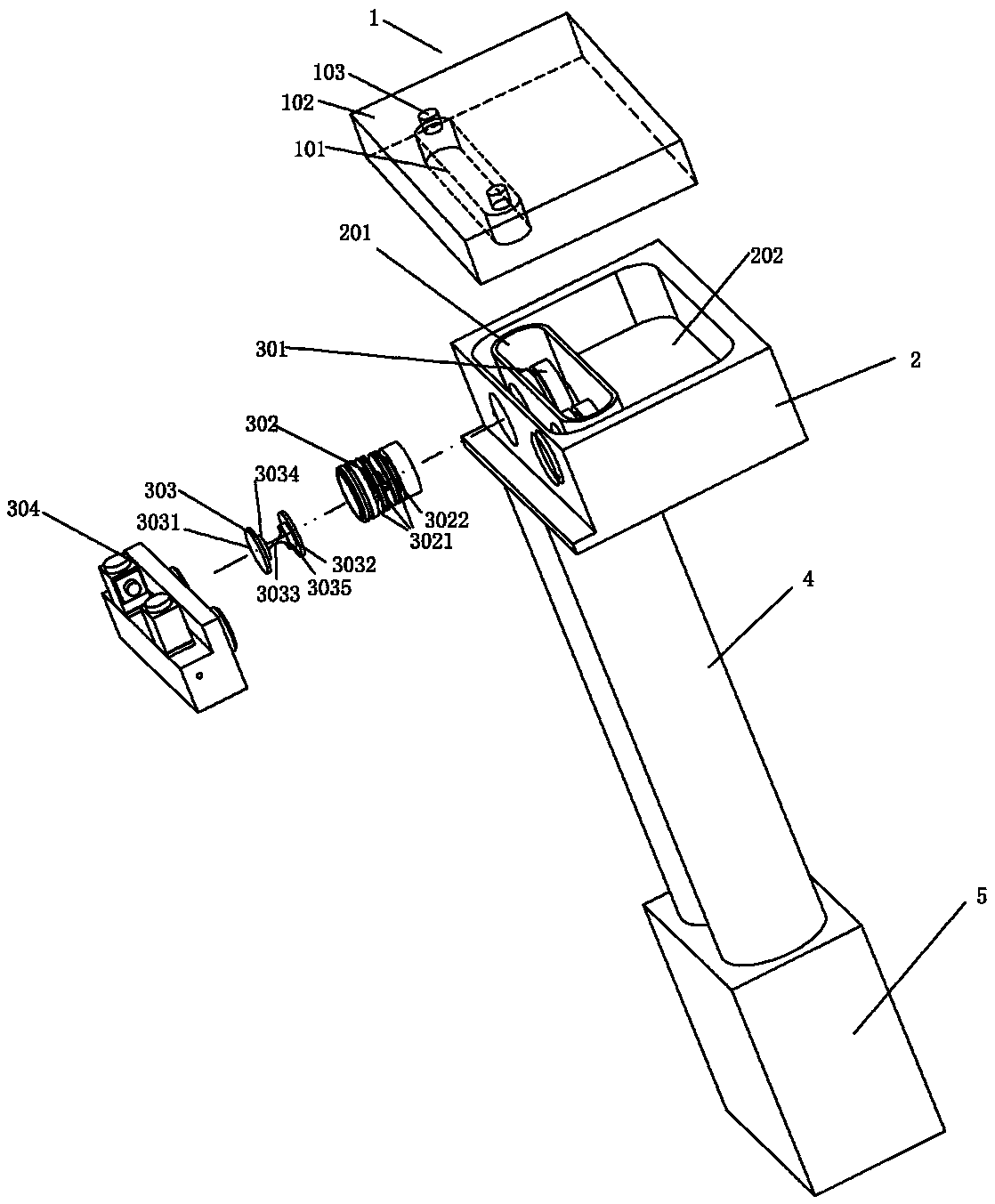

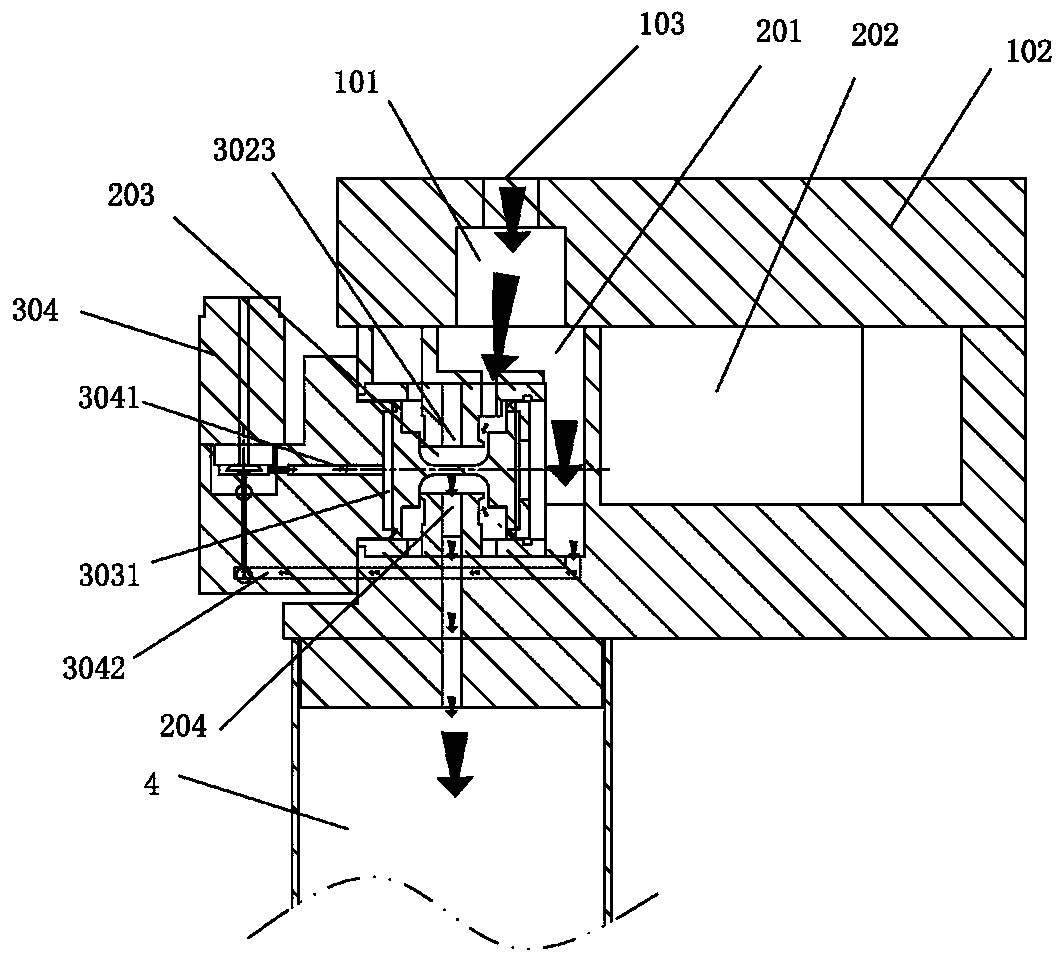

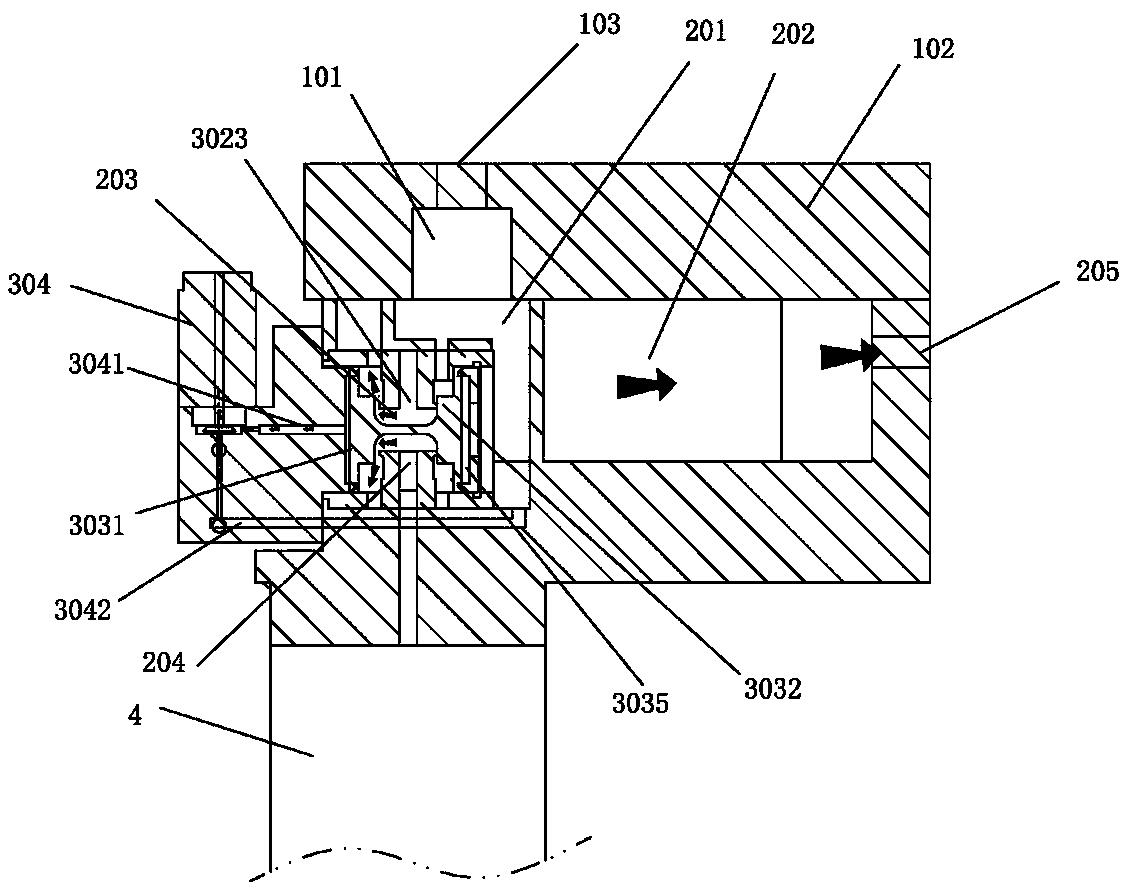

[0042] A molecular sieve gas circuit control device, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes an end cover 1, an air circuit body 2, and a control valve assembly 3. The end cover 1 is provided with an air inlet joint 103 connected to a high-pressure gas source. The end cover 1 is sealed and connected to the air circuit body 2. The control valve assembly 3 is arranged in the air circuit body 2, and the air circuit body 2 is provided with an air intake cavity 201 and an exhaust cavity 202, and the air intake cavity 201 is respectively connected with the air intake joint 103 communicates with the molecular sieve tower 4, the exhaust cavity 202 communicates with the exhaust hole 205 and the molecular sieve tower 4 respectively, and the control valve assembly 3 controls the opening and closing of the intake cavity 201 and the exhaust cavity 202.

[0043] The molecular sieve gas circuit control device of the present invention uses the air intake c...

Embodiment 2

[0065] Embodiment 2: an oxygen generator, comprising a molecular sieve gas path control device, a molecular sieve tower 4 and an oxygen storage 5, one end of the molecular sieve tower 4 communicates with the oxygen storage 5, and transmits oxygen in the oxygen storage 5, the An oxygen connector is provided on the oxygen storage 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com