Propane dehydrogenation process involving catalyst regeneration and reactor double-online switching

A propane dehydrogenation and reactor technology, which is used in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc. Costs, increased production, and the effect of long operating cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

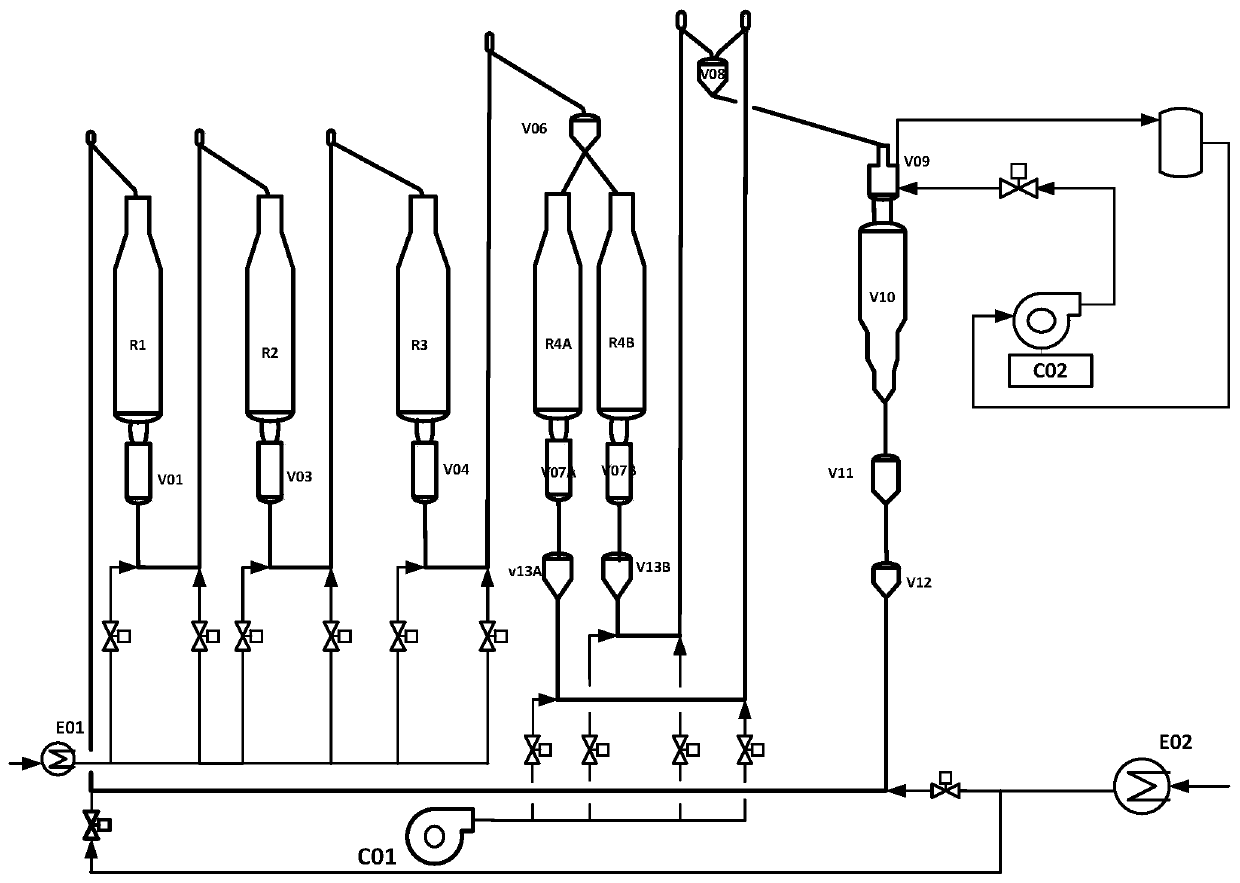

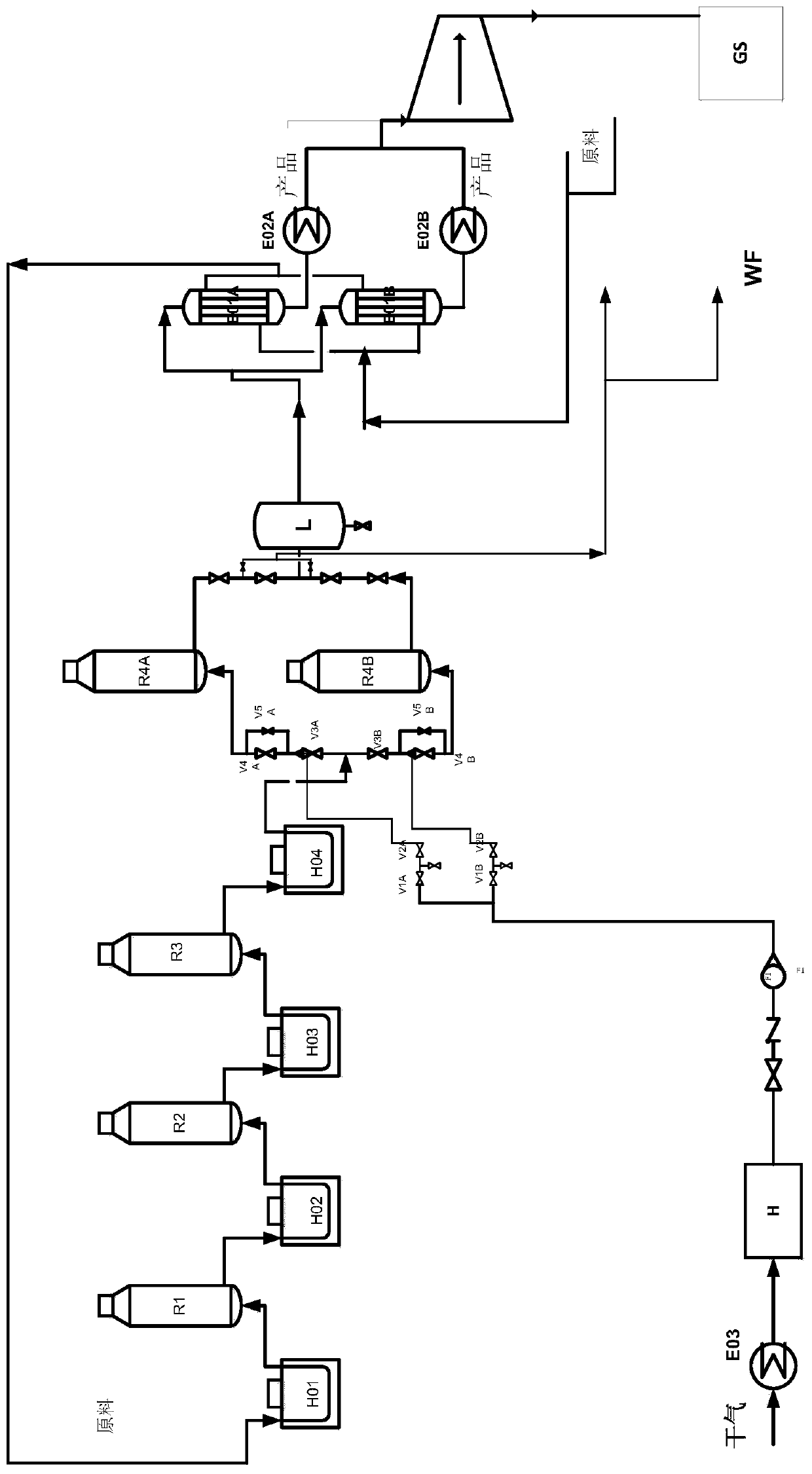

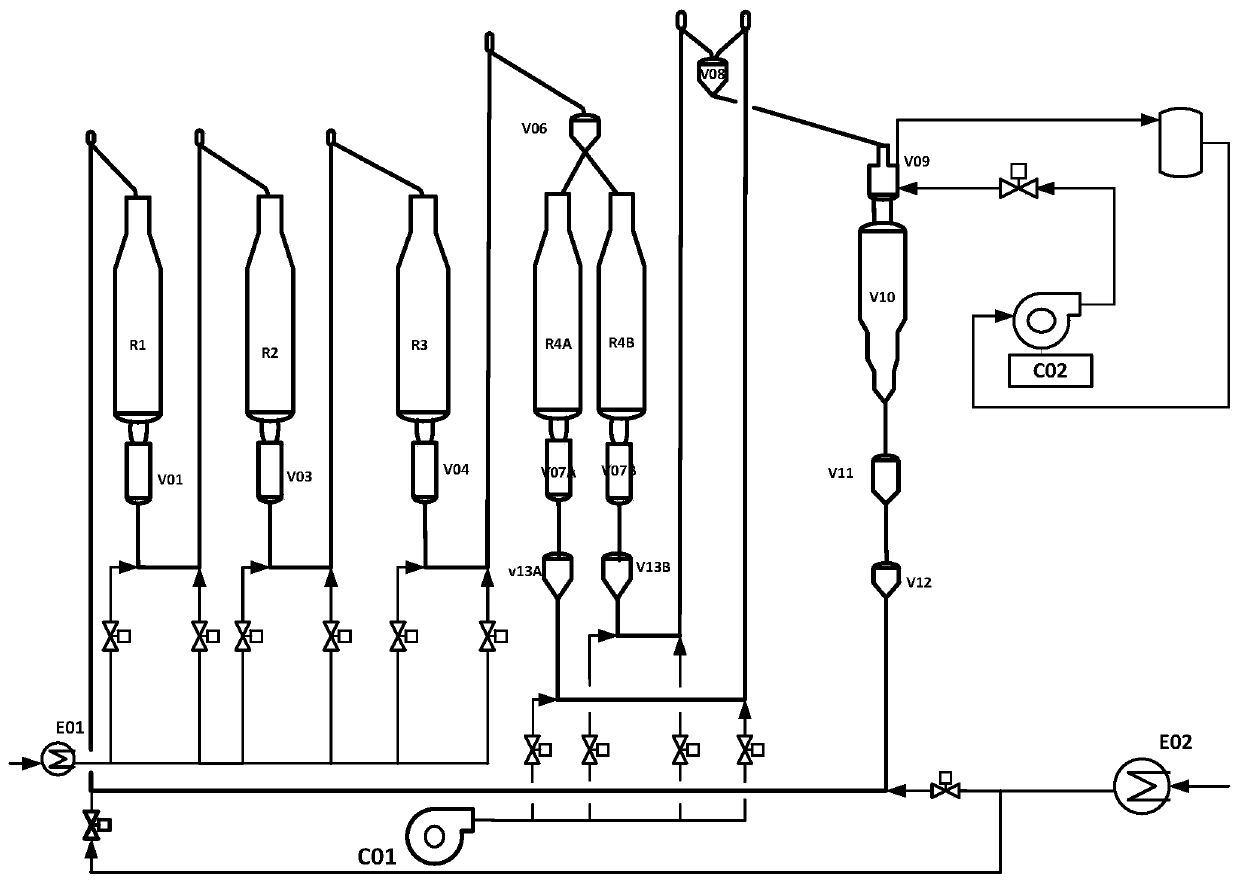

[0028] see figure 1 , the present invention relates to the propane dehydrogenation process of catalyst regeneration and double online switching of reactors, which comprises the following steps:

[0029] Catalytic dehydrogenation: The raw material exchanges heat with the product gas from the heat exchanger E01A (E01B is standby), then is heated to the reaction temperature by the heating furnace H01, enters the reactor R1, is then heated by the heating furnace H02, enters the reactor R2, and then Heated by the heating furnace H03 into the reactor R3, and then heated by the heating furnace H04A into the reactor R4A (R4B standby), the product gas from the reactor R4A enters the heat exchanger E01A through the buffer tank L (E01B standby), and the raw material After heat exchange, it passes through the water cooler E02A (E02B corresponds to the heat exchanger E01B), and then is sent to the separation system GS through the compressor for separation to obtain the final product propyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com