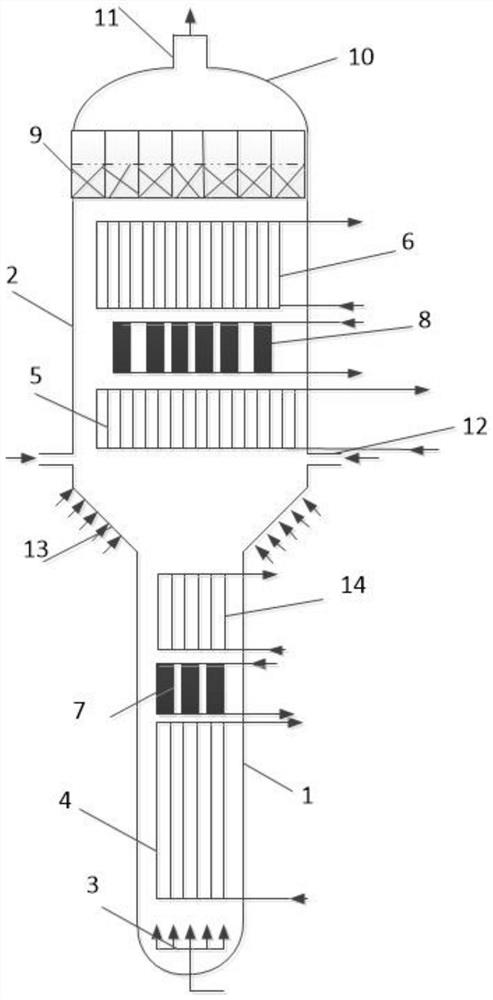

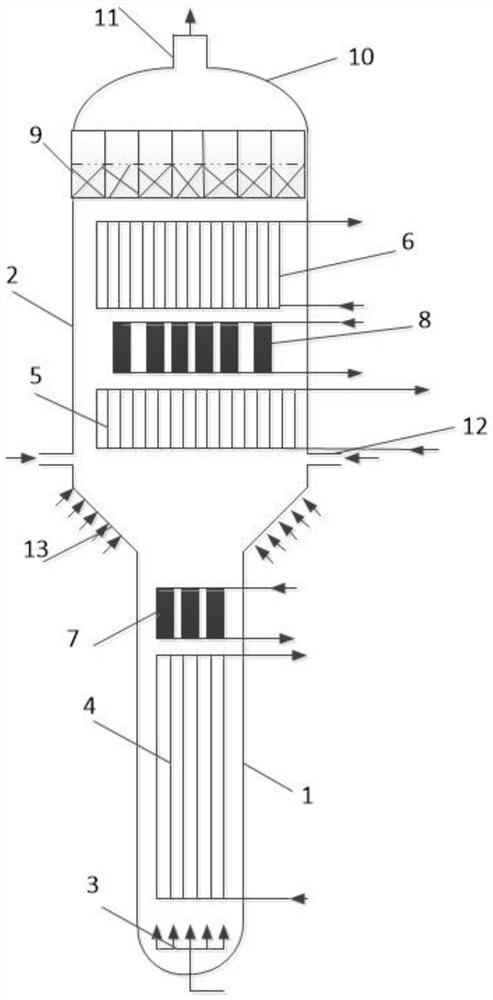

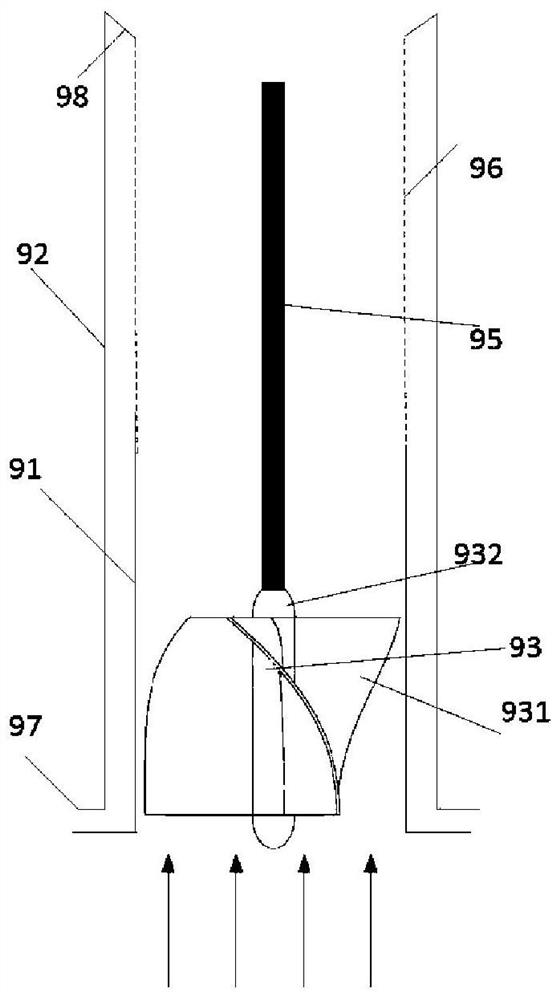

Multi-stage slurry bed reactor and working method thereof

A slurry bed and reactor technology, which is applied in the field of multi-stage slurry bed reactors, can solve the problems of low reaction efficiency, easy formation of a dilute phase zone by the catalyst, clogging of the external filter by the catalyst, etc. The effect of simple control and small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Embodiment: 200,000 tons of Fischer-Tropsch synthesis reactor comparative situation

[0054] According to the original slurry bed reactor with the same diameter and bottom air inlet, the industrial operation test was carried out. The temperature of the slurry bed reactor was 255°C, the pressure was 2.9MPa, and the superficial gas velocity at the reactor inlet was 0.25m / s. The single-pass conversion rate is 31%, wherein the incoming gas is fresh syngas and cycle gas, and the cycle gas enters from the bottom to occupy the volume occupied by the fresh gas, resulting in a reduction in the conversion rate of the fresh gas, and a small amount of solid particles will be entrained at the top of the reactor. Particles, which will cause these solid particles to enter and may clog the filter, or even reduce the life of the filter, and the fine catalyst is less active, theoretically need to be removed. The reactor of this patent adds an expansion section and changes the air intake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com