Polar polyolefin material and its preparation method and use

A polyolefin and polar technology, applied in the field of new polyolefin materials and their preparation, can solve the problems of reducing the molecular weight of copolymers, unfavorable polymer mechanical properties, etc., and achieve the effect of improving the activity of copolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the preparation method of the present invention, the polymerization temperature is preferably 40-120°C, such as 80°C; the ethylene pressure is preferably 1-15 atmospheres (atm), more preferably 3-9 atm; as the dimerization of the first comonomer The concentration of cyclopentadiene monomer or ethylidene norbornene monomer polar olefin monomer in the reaction solvent can be 0.01~10mol / L, more preferably 0.1~4mol / L; as the pole of the second comonomer The concentration of polar norbornene monomers or polar terminal olefin monomers in the reaction solvent is preferably 0.01-10mol / L, more preferably 0.1-2mol / L; the polymerization time can be 0.1-12h, preferably 1-12 hours, for example about 1 hour.

[0033] In the present invention, the copolymerization reaction can be carried out in the presence of an additionally added organic solvent, that is, the copolymerization reaction is carried out in a solution, which can be called solution polymerization. Preferably, the orga...

Embodiment 1-10

[0040] Example 1-10: Preparation and performance testing of polar polyolefin materials

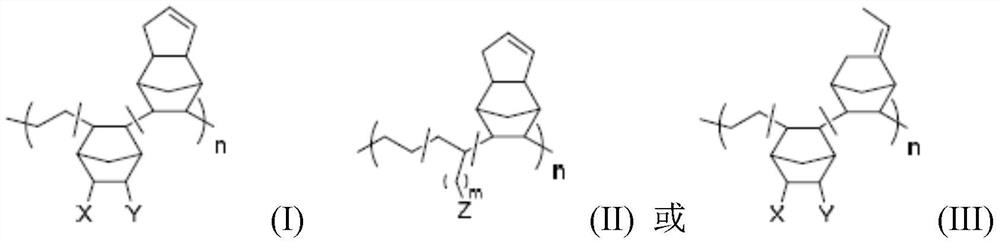

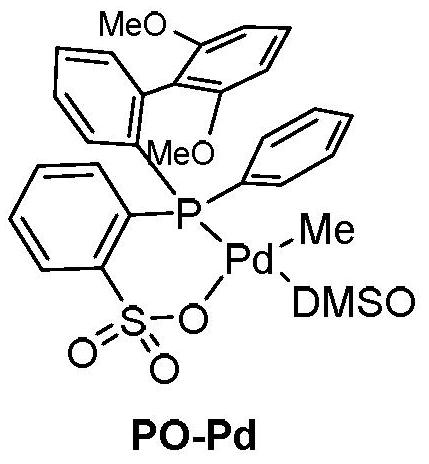

[0041] In the glove box, under a nitrogen atmosphere, the dicyclopentadiene monomer (DCPD) or Ethylidene norbornene monomer (ENB) and polar norbornene monomer or polar olefin monomer (5-norbornen-2-yl acetate (NB OAc ), 5-norbornene-2-methanol (NB OH ) or 10-undecylenic acid methyl ester (O1), 10-undecylenic acid (O2)), the respective molar concentrations are indicated in brackets after the corresponding comonomers. For example, when the total reactant volume is 30mL, for the random copolymer E / DCPD(1.5) / NB obtained in Example 1 OAc (0.5), the molar number of DCPD monomer is 45mmol, and NB OAc The molar number of the monomer is 15 mmol), and 20 μmol of the catalyst PO-Pd dissolved in 1 mL of dichloromethane is added to the reaction kettle. Then, connect the ethylene gas source pipeline to feed ethylene (monomer E) gas into the reactor, and after adjusting the ethylene pressure to 8atm,...

Embodiment 11-14

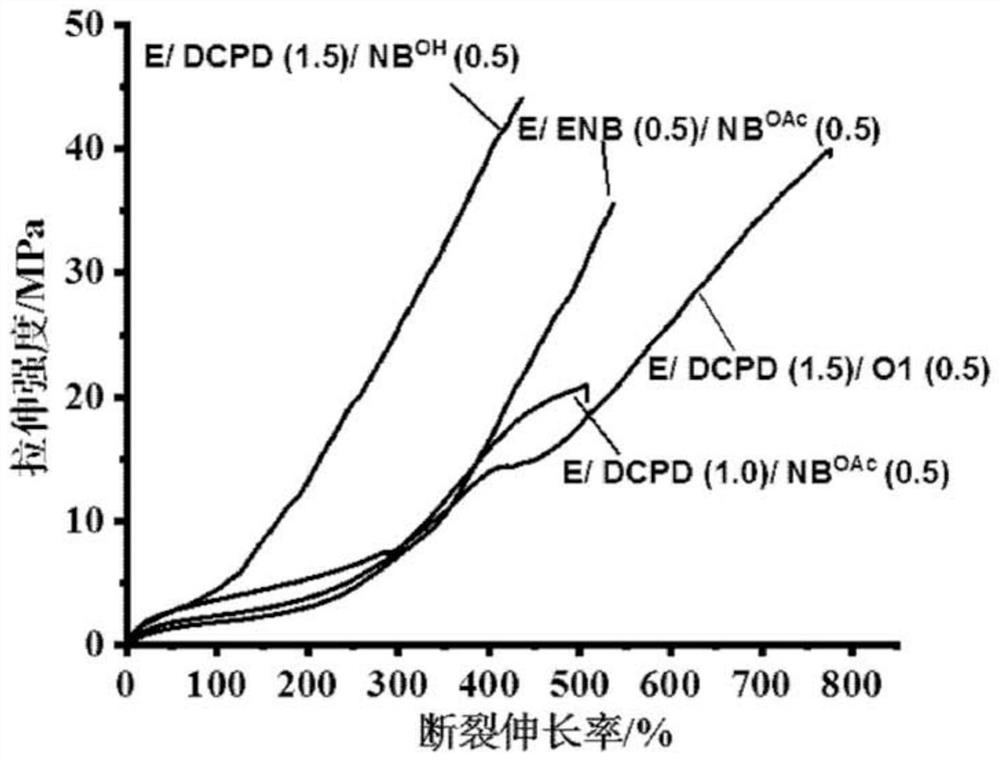

[0055] Examples 11-14: Mechanical property test of polar polyolefin materials

[0056] The polar polyolefin material obtained in the above embodiments 2, 3, 4 and 6 is made into a dumbbell-shaped sample (length 25mm*width 2mm*thickness 0.4mm), and the test of mechanical properties is carried out by a universal testing machine (UTM2502). The tensile strength and elongation at break results were obtained as figure 1 shown. Depend on figure 1 It can be seen that the polar polyolefin material of the present invention has excellent mechanical properties, its tensile strength is above about 20 MPa, even up to 40 MPa, and its elongation at break is above 400%, even up to 700% . Correspondingly, the polar polyolefin material of the present invention can have various applications, for example, it can be used as packaging material, automobile manufacturing material, electrical appliance manufacturing material, medical device manufacturing material or agricultural implement manufactur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com