Preparation method and preparation equipment of shell powder dry powder type coating material taking mesh macromolecules as film-forming material

A technology of film-forming materials and shell powder, which is applied in the field of preparation of shell powder dry powder coatings, can solve the problems of full mixing of shell powder and film-forming polymer mesh materials, so as to enhance exercise strength and activity, and enhance fireproof characteristics , the effect of high self-defense ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

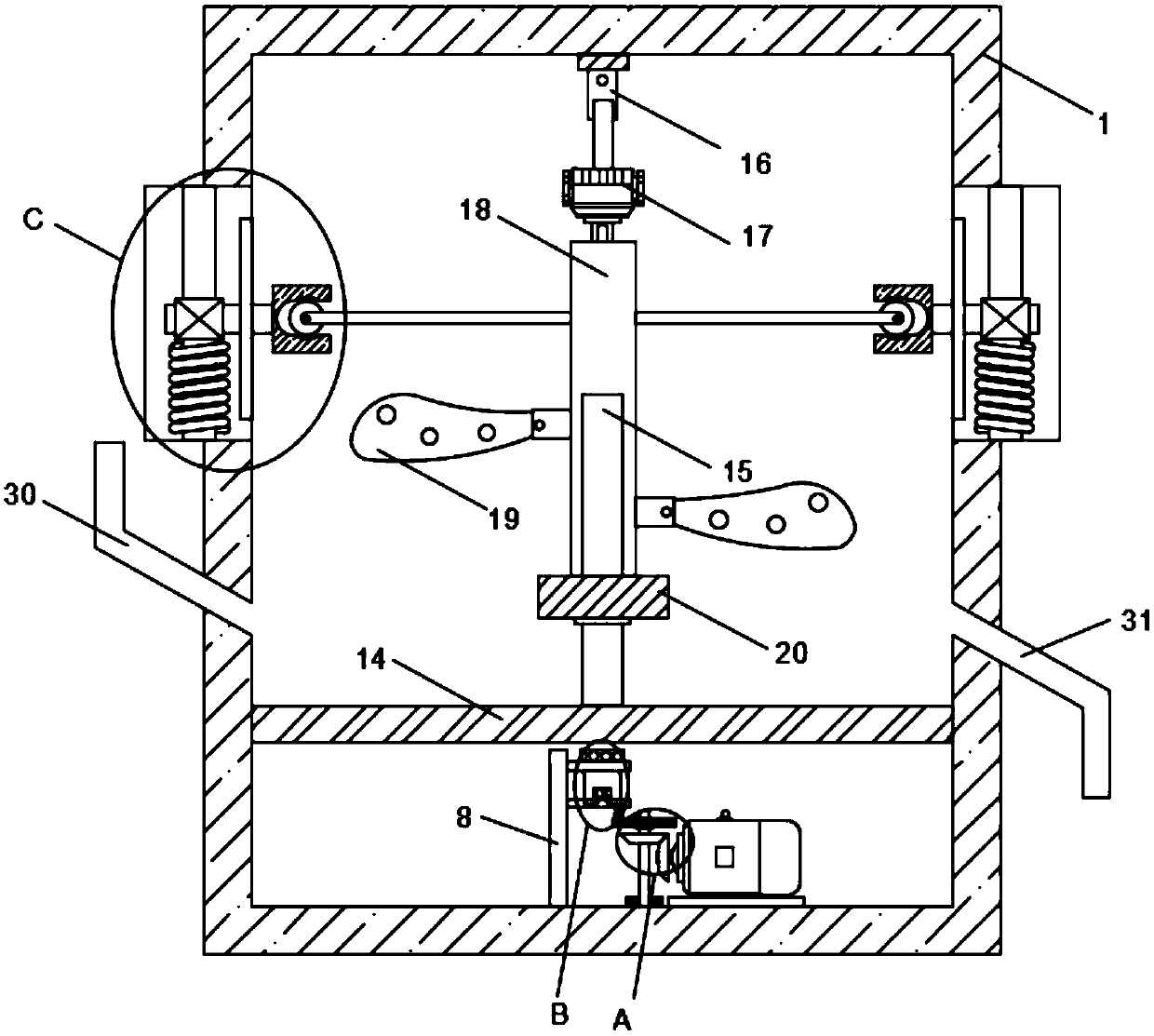

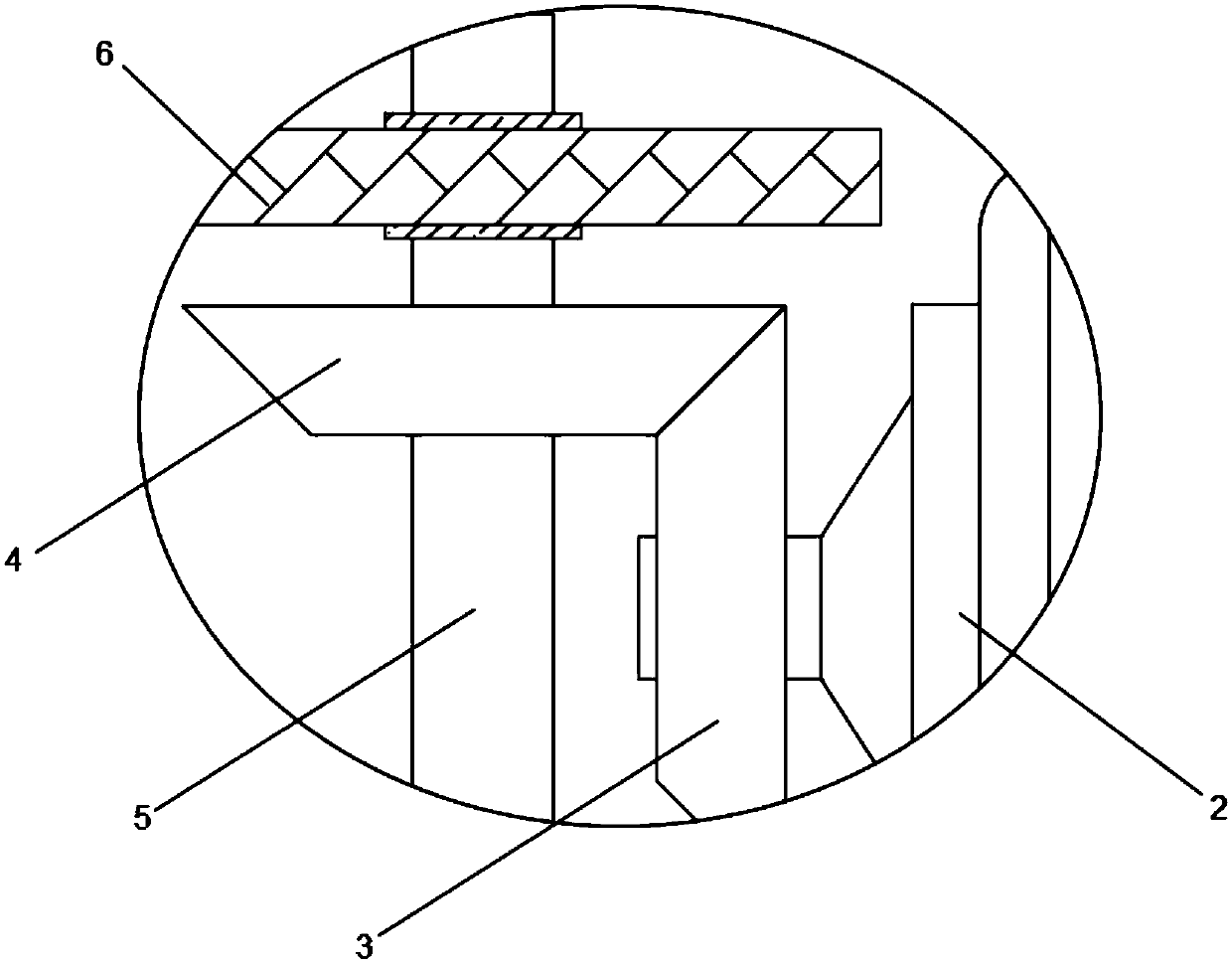

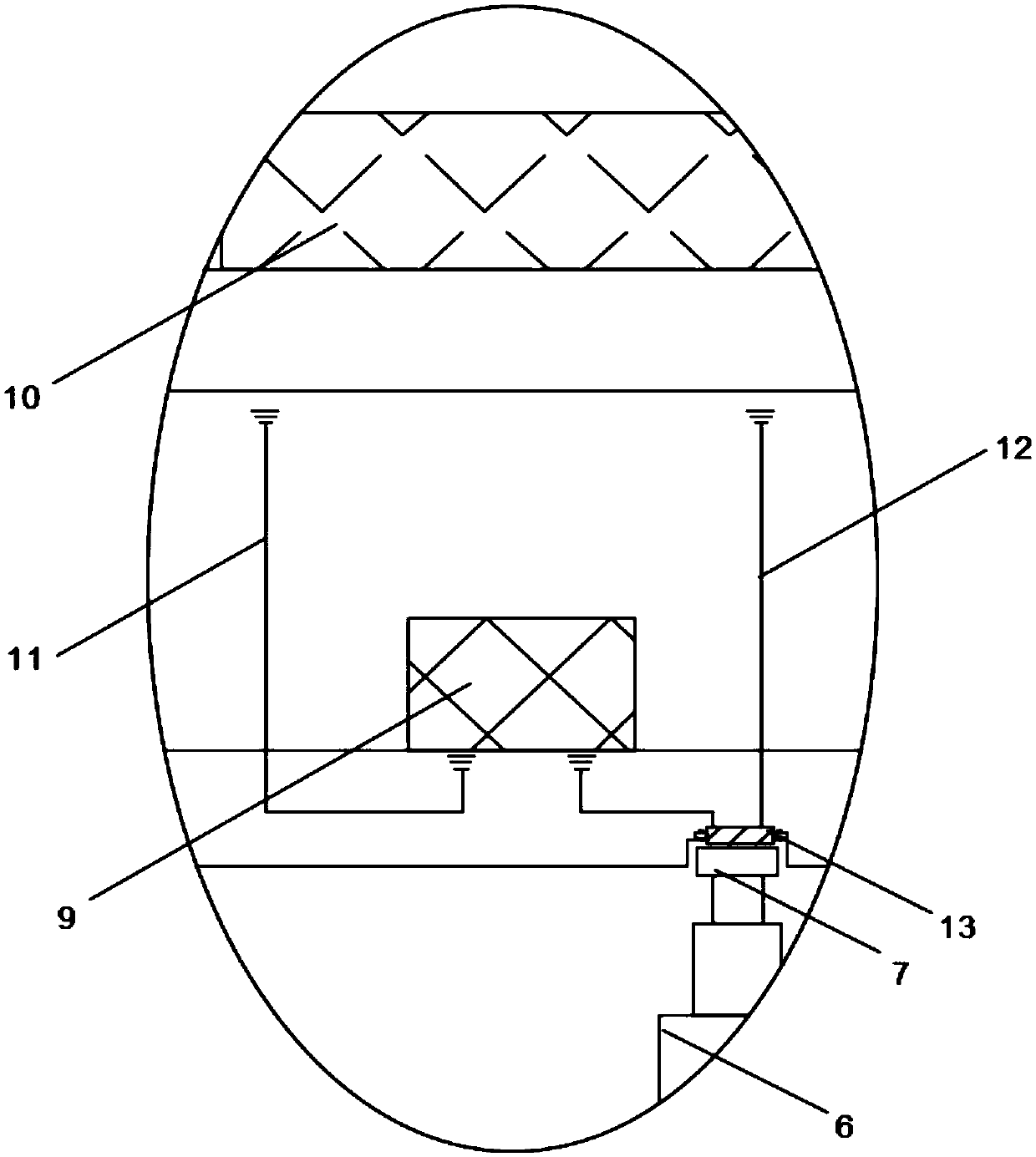

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

[0027] Reference Figure 1-4 , A preparation method of shell powder dry powder coating using mesh polymer as a film-forming material, comprising the following steps:

[0028] Step 1. Selection and configuration of basic raw materials: select a mesh polymer with a thickness of 0.05cm-0.08cm as the film-forming material, select the shell powder fine particles with a porous fibrous double helix structure, and the diameter of the shell powder fine particles is 0.03cm -0.06cm, select kaolin that has been calcined at least 120℃, and the diameter of kaolin particles is less than 0.05cm, select talc with a particle diameter of 0.01cm-0.03cm, and sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com