Graphene electric heating piece and manufacturing process and application thereof

A production process, graphene technology, applied in the field of reducing environmental pollution, can solve the problems of changing smoking habits of smokers, small heating area of resistance wire, increasing product cost, etc., so as to abandon traditional smoking habits, reduce public health hazards, and meet the needs of users. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

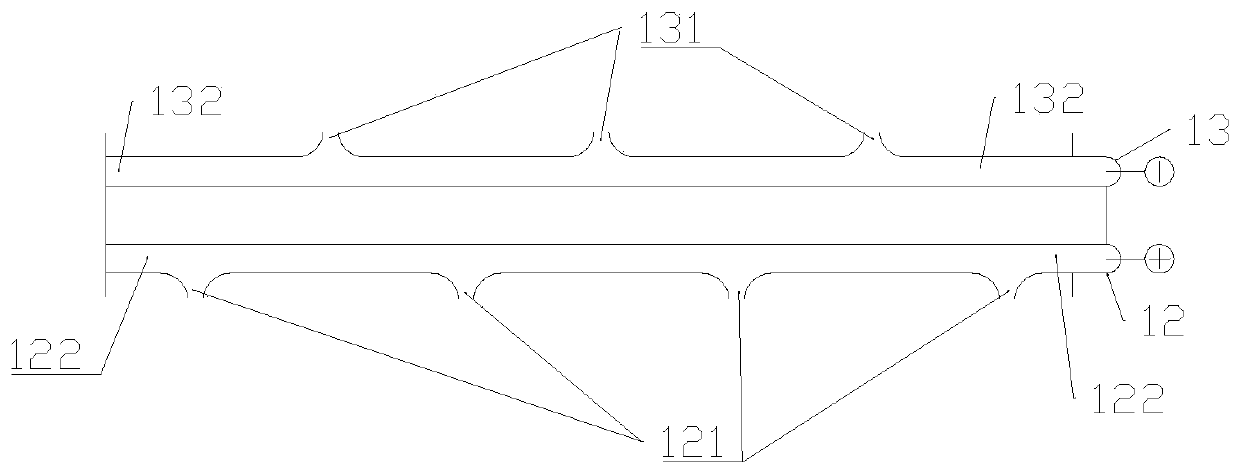

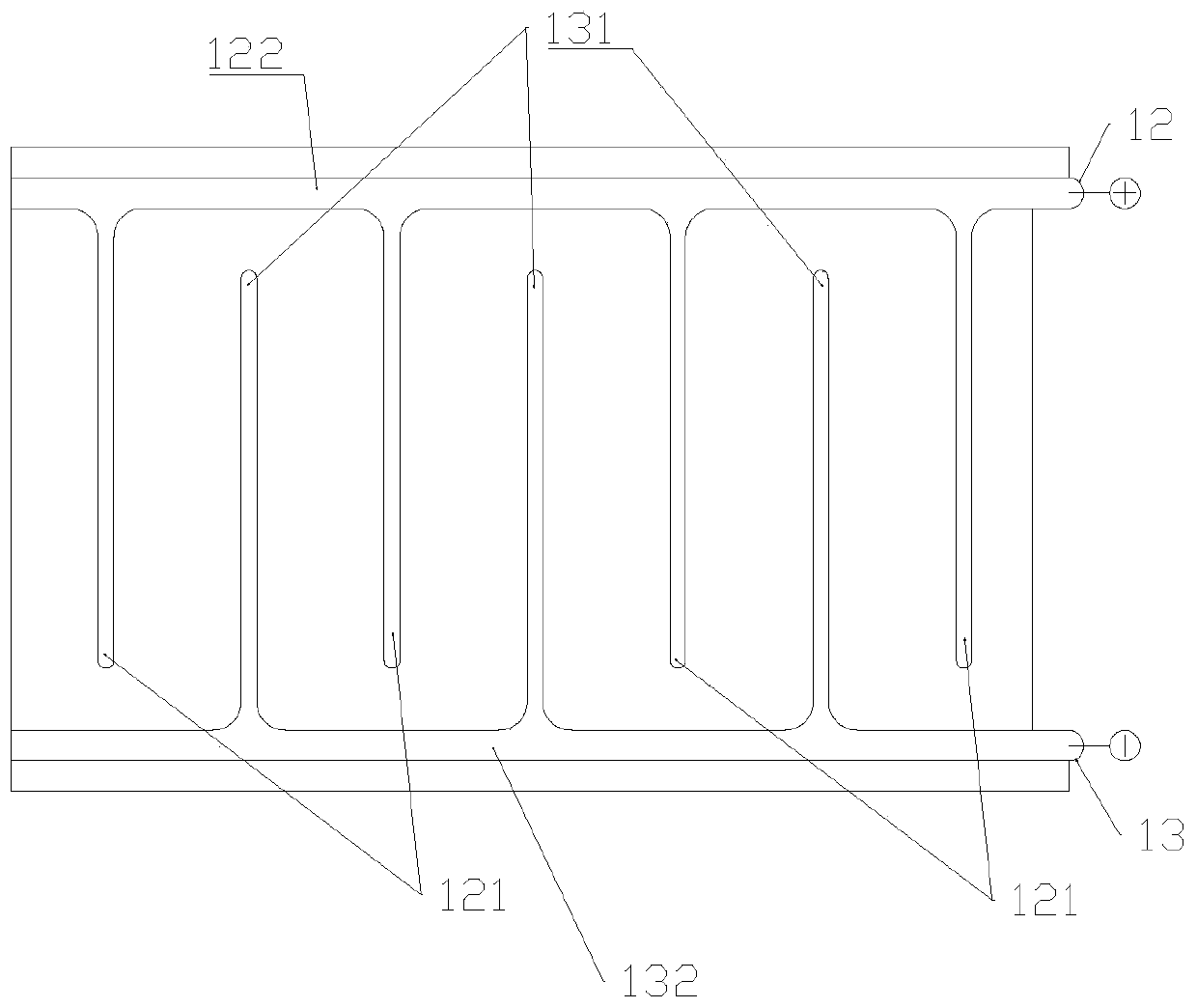

[0037] see figure 1 as well as figure 2 , a graphene electric heating element 1, comprising a positive electrode conductive grid 12, a negative electrode conductive grid 13 and a graphene electrothermal coating 11, the positive electrode conductive grid 12 and the negative electrode conductive grid 13 pass through the graphene electric The thermogenic coating 11 is attached. The graphene electrothermal coating is turned on after being energized by the positive conductive grid and the negative conductive grid.

[0038] As can be seen from the above description, the beneficial effects of the present invention are: the graphene electrothermal coating 11 containing graphene material utilizes the positive electrode conductive grid 12 and the negative electrode conductive grid 13 to form a conductive network, the positive electrode conductive grid 12 and the negative electrode conductive grid 13 Heat is generated when the graphene electrothermal coating 11 is powered. Due to the...

Embodiment 2

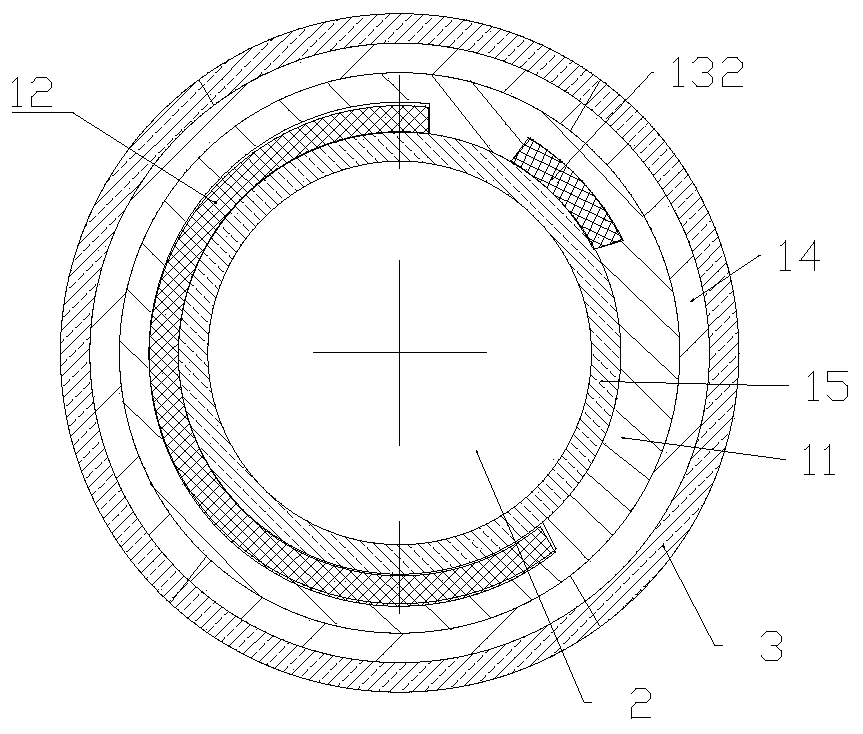

[0040] On the basis of the above embodiments, the graphene electrothermal element 1 further includes a protective film layer 14 for preventing oxidation of the graphene electrothermal coating 11 . The graphene electrothermal coating 11 is easy to oxidize at high temperature and reduces the service life, so a protective film layer 14 is provided to prevent it from oxidizing.

Embodiment 3

[0042] Based on the above examples, please refer to image 3 , Figure 4 as well as Figure 5, the graphene electrothermal element 1 also includes a support substrate 15 for supporting the graphene electrothermal coating 11, and the graphene electrothermal coating 11 is located between the support substrate 15 and the Between the above protective film layers 14. In addition to supporting the graphene electrothermal coating 11 , the supporting substrate 15 also protects the graphene electrothermal coating 11 together with the protective film layer 14 to prevent the graphene electrothermal coating 11 from being oxidized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrier mobility | aaaaa | aaaaa |

| Electron mobility | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com