Gear profile heat treatment device for tank crawler drive gear

A technology for heat treatment devices and driving gears, applied in heat treatment furnaces, heat treatment equipment, motor vehicles, etc., can solve problems such as excessive hardness at the tip and root of the tooth, low surface hardness of the tooth profile, uneven depth of induction hardening of the driving gear, etc., to achieve Energy saving, environmental protection, automation degree, small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

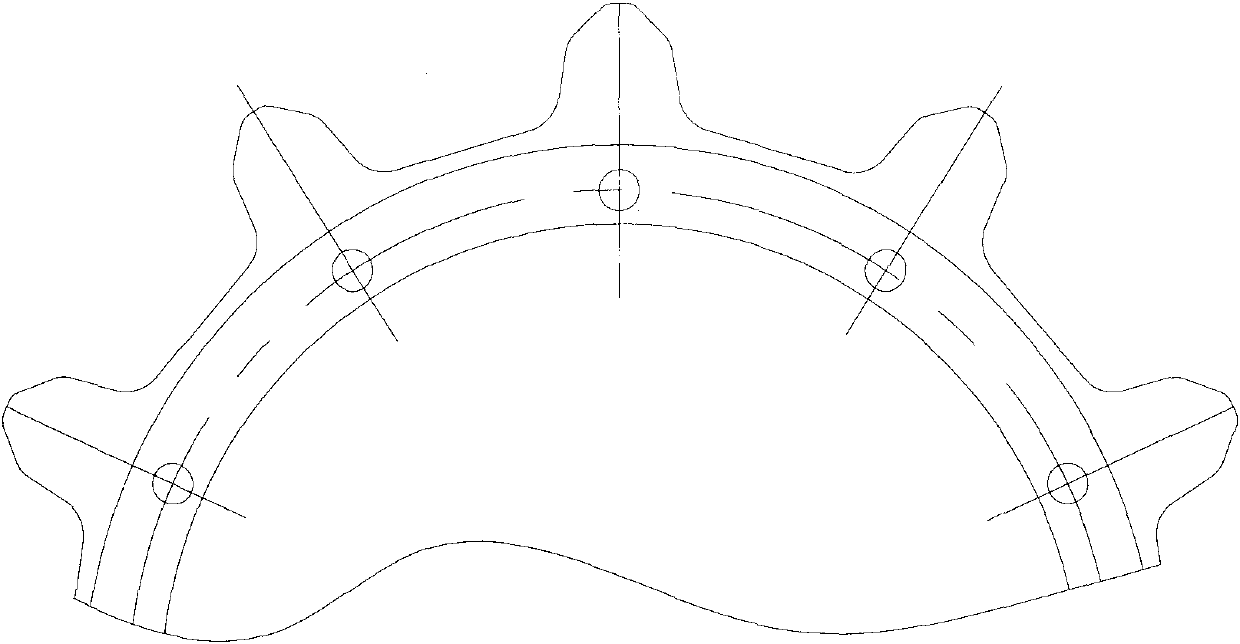

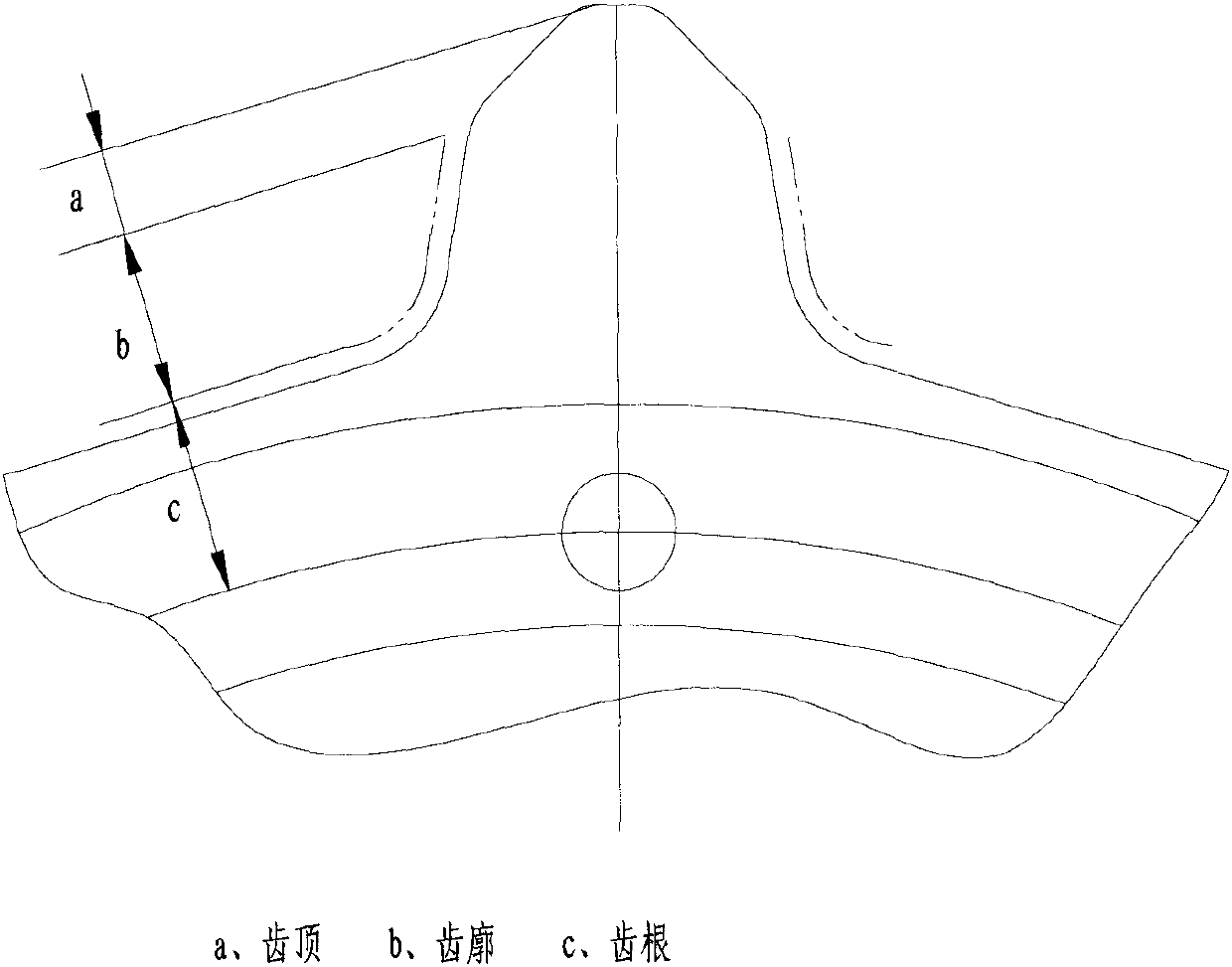

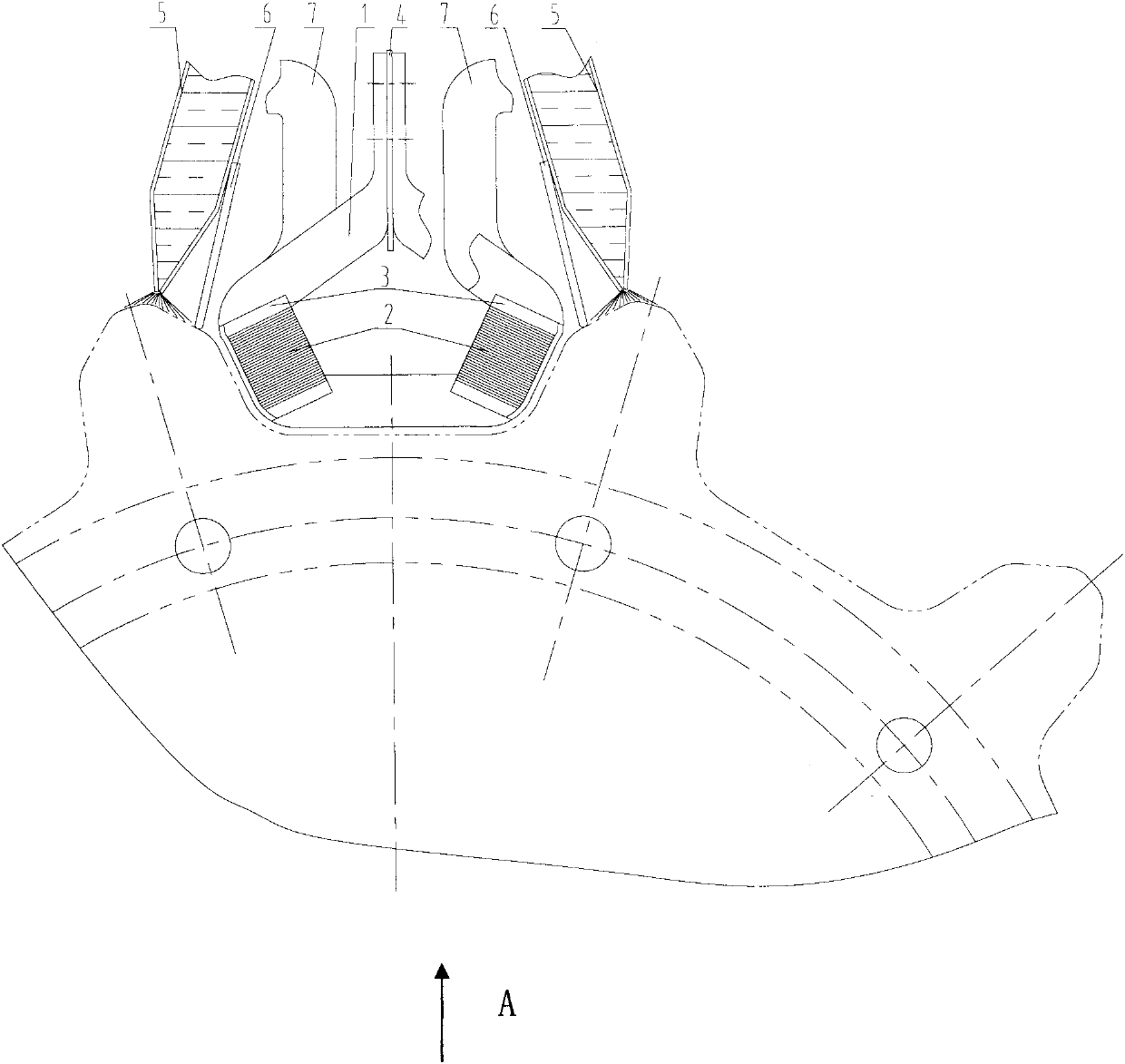

[0019] Such as Figure 1-Figure 7 As shown, the heat treatment device of the present invention essentially utilizes a mode sensor to realize the heat treatment of the active teeth of the track transmission part of the tank vehicle. The mode sensor consists of two parts: induction heating device and separate cooling device (see image 3 , Figure 4 , Figure 5 , Figure 6 ). Induction heating device (see Figure 5 ) consists of a copper billet 1 imitating the shape of the tooth profile, a number of silicon optical sheets 2 of magnetizers (see Figure 7 ), an insulating plate 4 and a water flusher 5 for preventing tooth tops from being heated, and a heat insulating plate 6 to form. The copper billet 1 used as the conductor of the inductor is fixed on the quenching machine with screws, the 0.2mm thick silicon light sheet 2 is not bonded with an adhesive, and is directly inserted into the groove of the conductor copper plate 3, and the water flusher 5 and the heat shield pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com