Expanded feed density control device

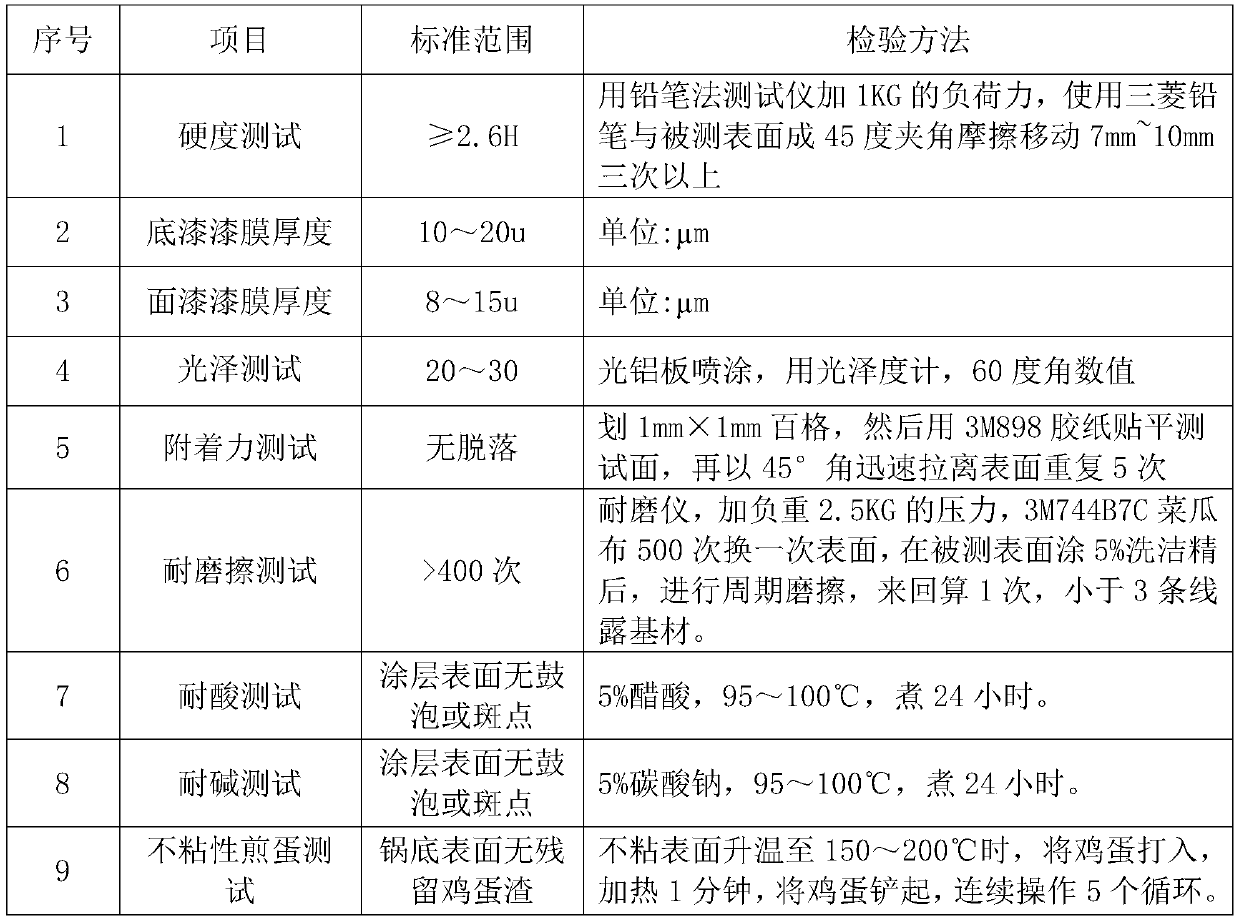

A technology of density control and extruded feed, applied in feed, epoxy resin coating, food science, etc., can solve the problems of poor blanking smoothness, affecting production efficiency, feeding stuck, etc., to improve the speed of unloading, Enhances usability and relieves stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

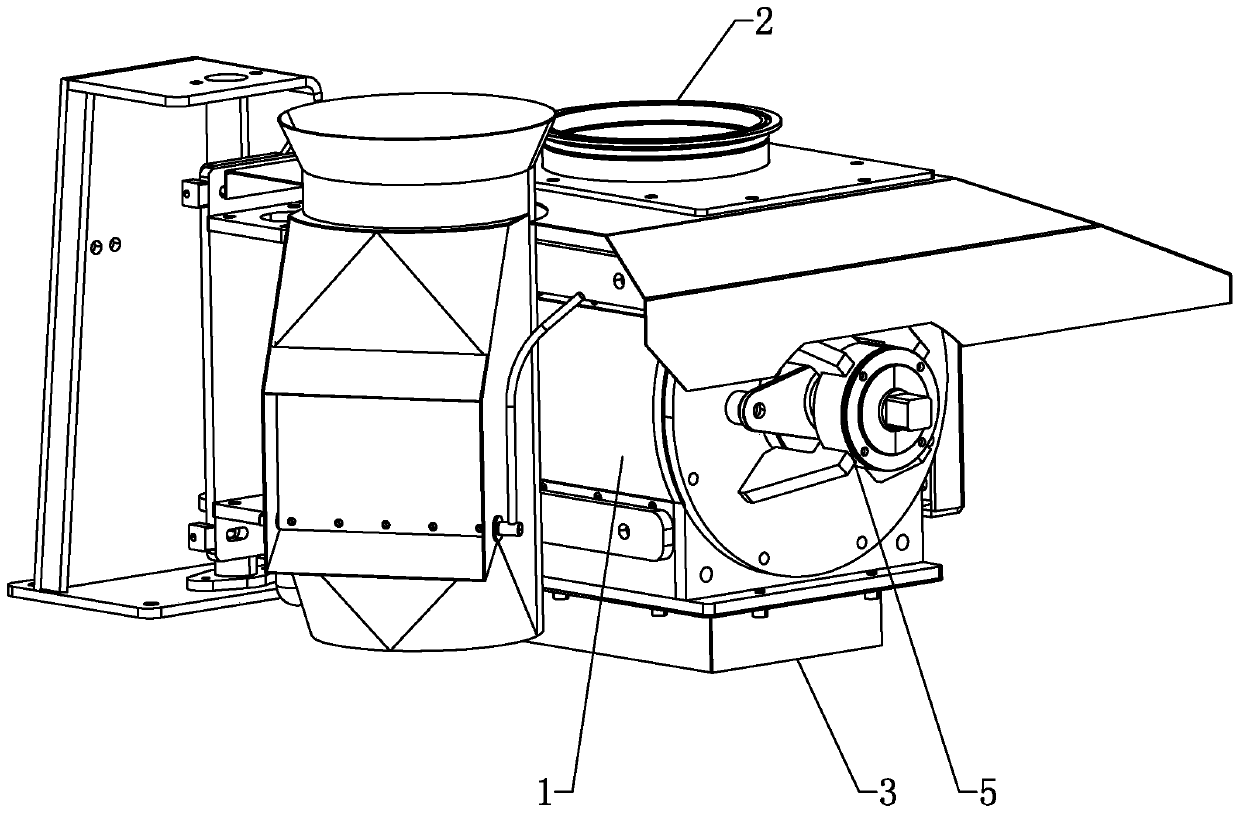

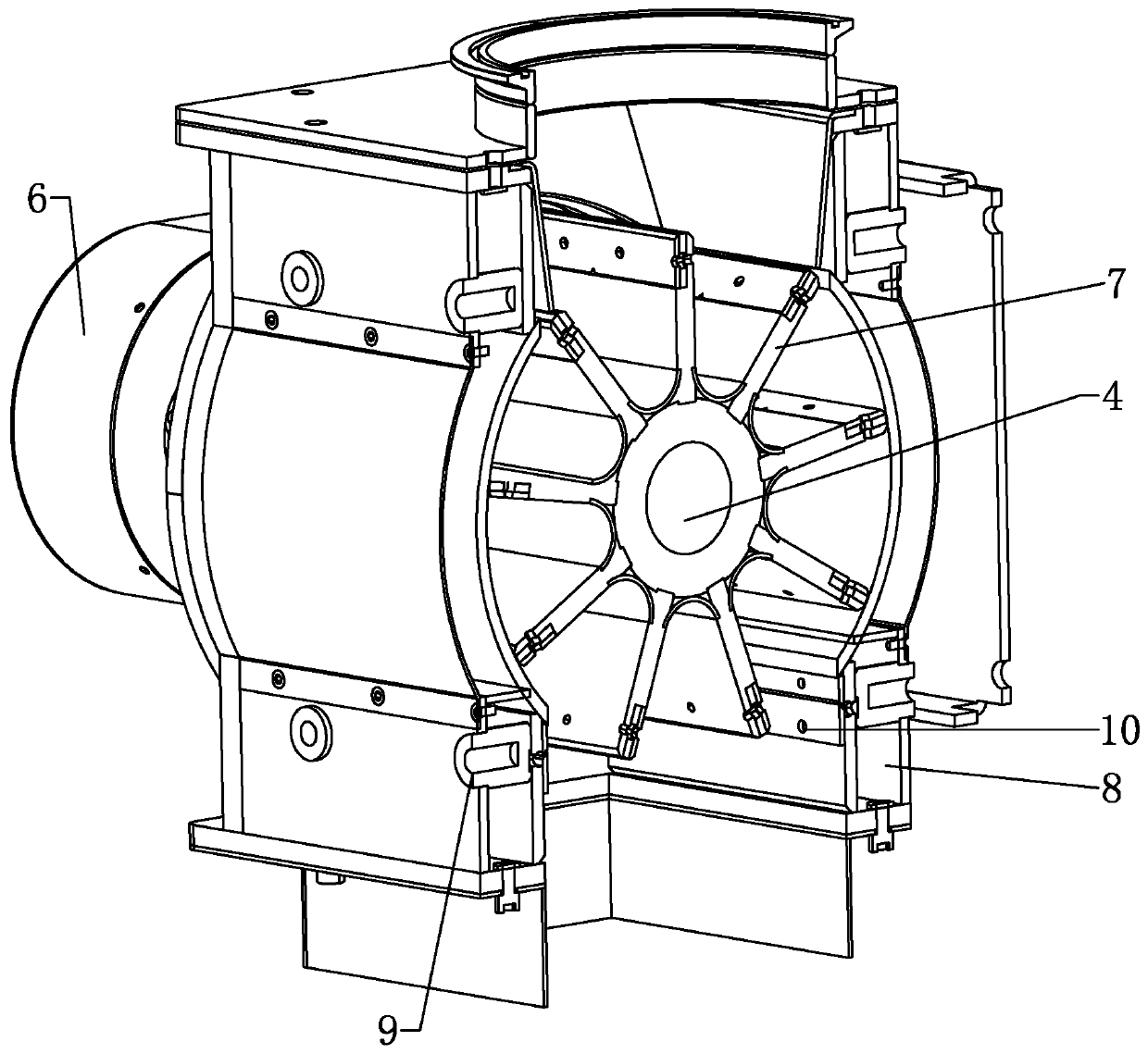

[0021] A device for controlling the density of extruded feed, such as figure 1 as well as figure 2 As shown, it includes a box body 1 , a feed inlet 2 is arranged on the top of the box body 1 , and a discharge outlet 3 is arranged at the bottom of the box body 1 . In addition, a rotating shaft 4 , a bearing 5 , a driving motor 6 and blades 7 are also included. Wherein, the rotating shaft 4 is located inside the box body 1, the number of bearings 5 is provided with two and fixed on both sides of the box body 1, and the two bearings 5 are respectively located at the two ends of the rotating shaft 4 to support the rotating shaft 4; the driving motor 6 and the box body 1 is fixed, and at the same time, the output shaft of the drive motor 6 is connected to the bearing 5 in transmission; the number of blades 7 is provided with several pieces, in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com