Preparation method of hydrogenation catalyst for treating dioxins in garbage gasification tail gas

A hydrogenation catalyst, a technology for gasification tail gas, which is applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve problems such as inapplicability, achieve high-efficiency dioxin generation, good adaptability, reduce Effects of Dioxin Components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

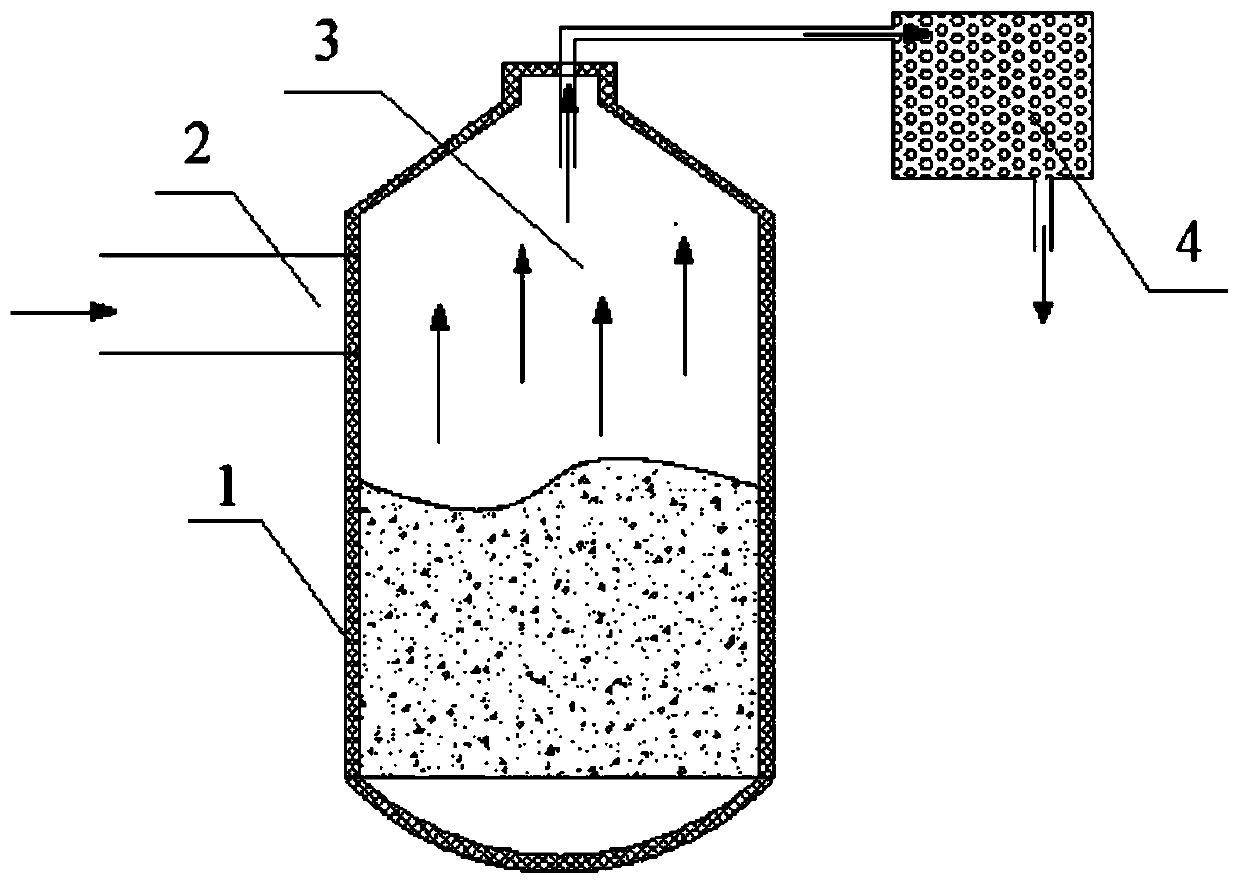

Image

Examples

Embodiment 1

[0032] a) Take 30g of lignite in a 500mL porcelain crucible, add 3mL of water and stir evenly, cover the crucible and place it in a muffle furnace for coking. The heating program of the muffle furnace is as follows: firstly, the temperature is raised to 300°C in 30 minutes, then raised to 1150°C at a rate of 3°C / min, and finally stays at 1150°C for 30 minutes. Finally, the muffle furnace cooling program is set, and the coke is taken out for later use when the temperature drops to room temperature.

[0033] b) Weigh 5 g of the lignite coke prepared in step a) and disperse it in 80 mL of ethylene glycol solvent, ultrasonically make it into a uniform dispersion, and weigh 5 mmol NiSO 4 ·6H 2 O, 5mmol FeSO 4 ·7H 2 O, 10 mmol Na 2 S 2 o 3 ·5H 2 O (sulfur source) was slowly added to lignite coke ethylene glycol turbid liquid, stirred and dissolved by a magnetic stirrer for 10 minutes, the mixture was transferred to a polytetrafluoroethylene-lined autoclave, sealed and placed ...

Embodiment 2

[0036] a) Take 30g of lignite in a 500mL porcelain crucible, add 3mL of water and stir evenly, cover the crucible and place it in a muffle furnace for coking. The heating program of the muffle furnace is as follows: firstly, the temperature is raised to 300°C in 30 minutes, then raised to 1150°C at a rate of 3°C / min, and finally stays at 1150°C for 30 minutes. Finally, the muffle furnace cooling program is set, and the coke is taken out for later use when the temperature drops to room temperature.

[0037] b) Weigh 5 g of the lignite coke prepared in step a) and disperse it in 80 mL of ethylene glycol solvent, ultrasonically make it into a uniform dispersion, and weigh 5 mmol NiSO 4 ·6H 2 O, 5mmol FeSO 4 ·7H 2 O, 10mmol thiourea (sulfur source) was slowly added to lignite coke ethylene glycol turbid liquid, stirred and dissolved by a magnetic stirrer for 10min, the mixture was transferred to a polytetrafluoroethylene-lined autoclave, sealed and placed in an oven at 180°C A...

Embodiment 3

[0039] a) Take 30g of lignite in a 500mL porcelain crucible, add 3mL of water and stir evenly, cover the crucible and place it in a muffle furnace for coking. The heating program of the muffle furnace is as follows: firstly, the temperature is raised to 300°C in 30 minutes, then raised to 1150°C at a rate of 3°C / min, and finally stays at 1150°C for 30 minutes. Finally, the muffle furnace cooling program is set, and the coke is taken out for later use when the temperature drops to room temperature.

[0040] b) Weigh 5 g of the lignite coke prepared in step a) and disperse it in 80 mL of ethylene glycol solvent, ultrasonically make it into a uniform dispersion, and weigh 5 mmol NiSO 4 ·6H 2 O, 5mmol FeSO 4 ·7H 2 O, 10mmol CS 2 (Sulphur source) was slowly added to lignite coke ethylene glycol turbid liquid, stirred and dissolved by a magnetic stirrer for 10min, the mixture was transferred to a polytetrafluoroethylene-lined autoclave, sealed and placed in an oven for 20h at 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com