High sealing performance device for mining drill bit polishing

一种高密封、性能的技术,应用在表面抛光的机床、适用于磨削工件边缘的机床、磨削驱动装置等方向,能够解决很难满足刀具抛光的需要、影响加工效率和质量、易产生大灰尘等问题,达到功能齐全、生产成本低、提高质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

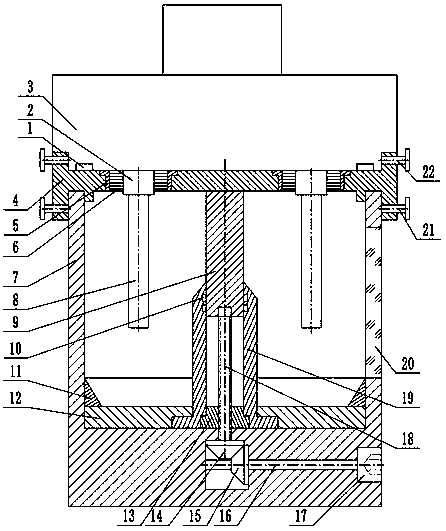

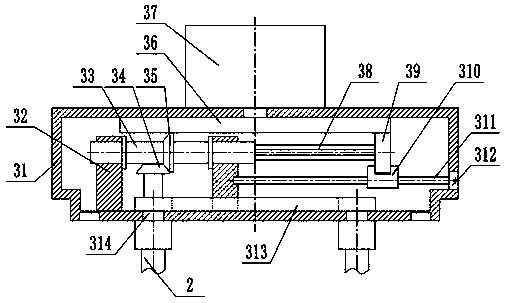

[0019] like figure 1 As shown, this specific embodiment adopts the following technical solutions: a high sealing performance device for mining drill bit polishing, including a sealing gasket 1, a tool holder 2, a driving mechanism 3, a cover 4, a fixed sleeve body 5, and bristles 6 , polishing shell 7, cutter 8, fixed shaft 9, sealing ring 10, cleaning ring 11, movable plate 12, nut seat 13, gear one 14, gear two 15, connecting shaft 16, rotating head 17, screw rod 18, movable sleeve 19. Observation port 20, locking screw 1 21 and locking screw 2 22; the output shaft on the lower side of the driving mechanism 3 is fixedly connected with the tool chuck 2, and the lower side of the driving mechanism 3 passes through several locking screws Two 22 are fixedly connected on the cover 4, and a gasket 1 is arranged on the outside between the bottom surface of the driving mechanism 3 and the top surface of the cover 4; the lower side of the tool holder 2 is fixedly connected with a cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com